Automatic control system for operation and protection of electrodialysis system

An automatic control system, electrodialysis technology, applied in water treatment parameter control, water/sludge/sewage treatment, filtration treatment, etc., can solve the problem of ion migration speed reduction, blockage of membrane stack water flow channel, membrane matrix corrosion damage, etc. problems, to achieve the effect of reducing the probability of equipment damage or pollution, reducing labor intensity, and reducing operating accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below through specific embodiments and accompanying drawings.

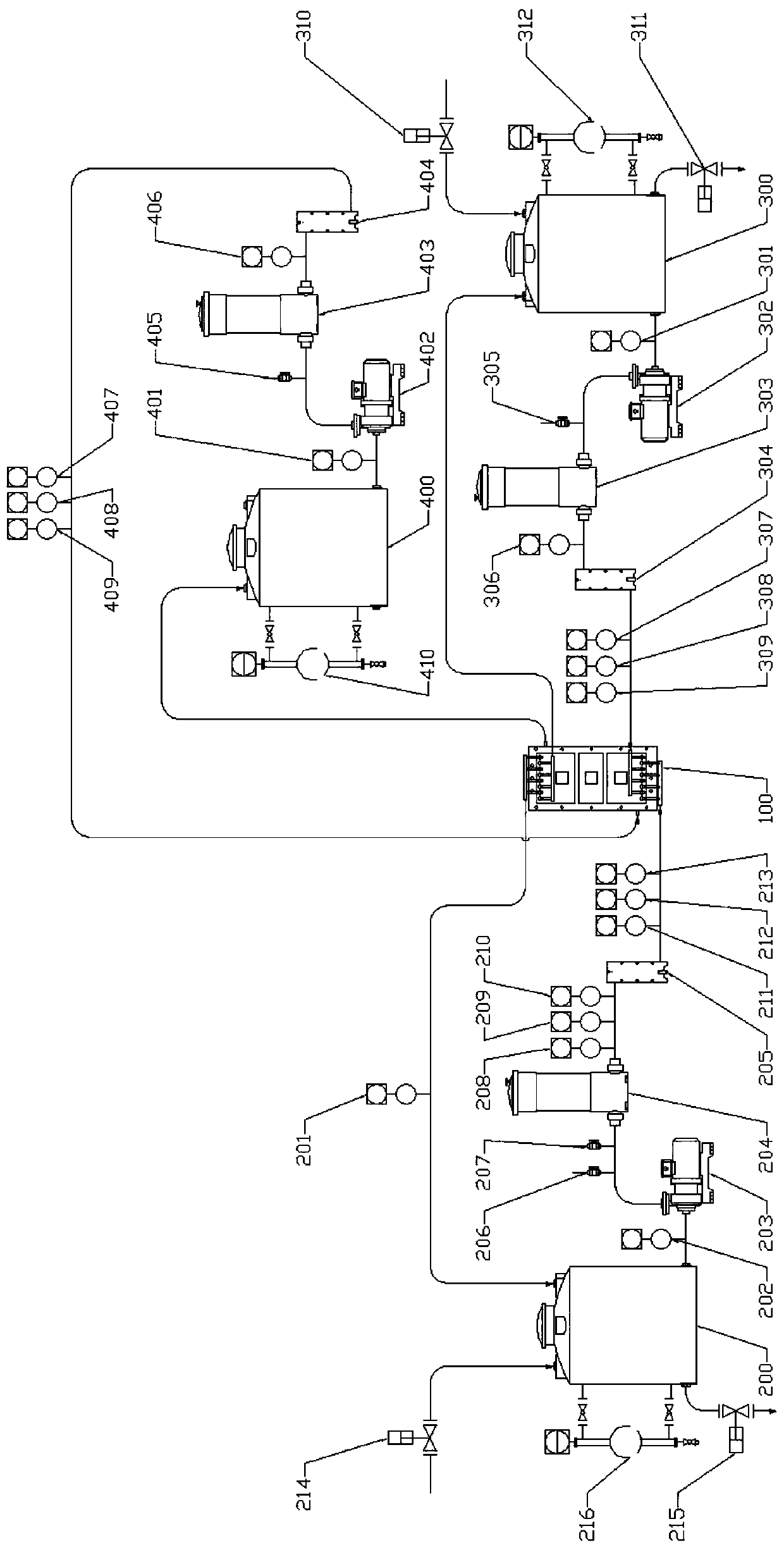

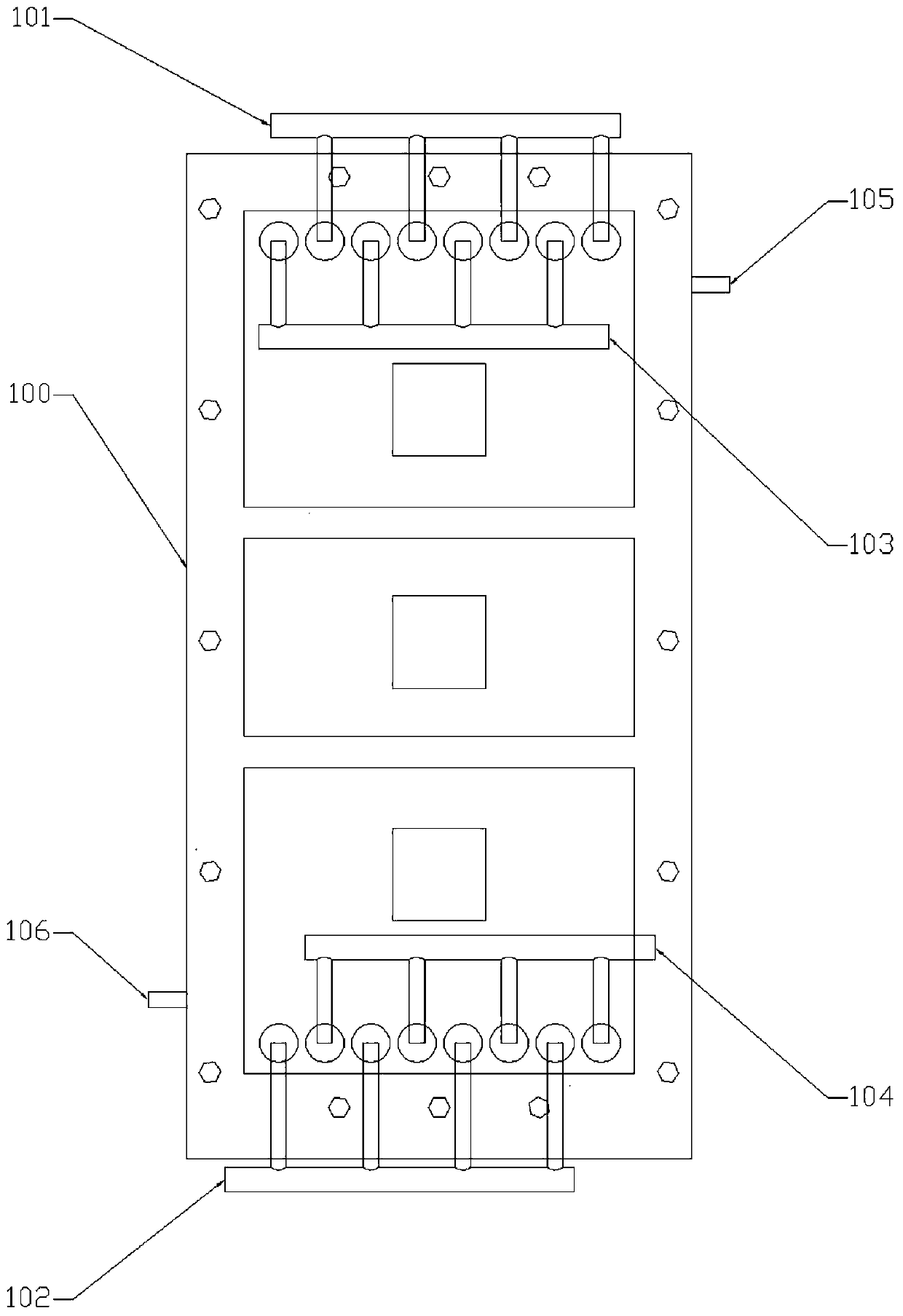

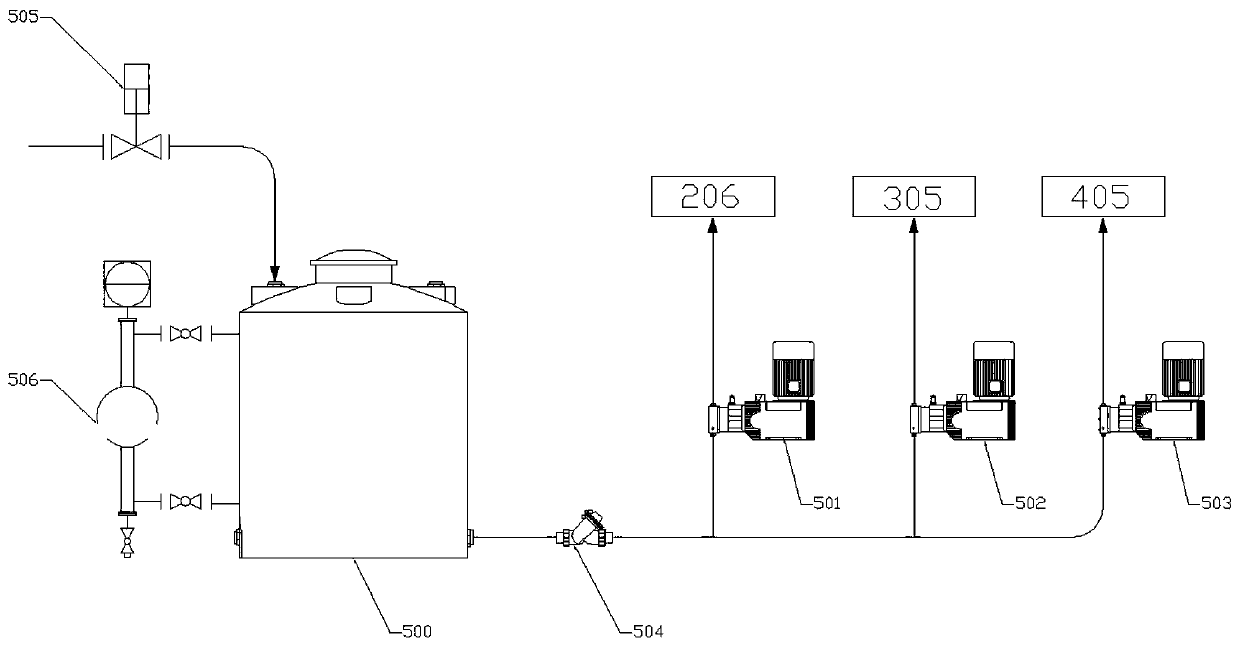

[0039] The implementation method is as follows: Figure 1-2 As shown, an automatic control system for the operation and protection of an electrodialysis system includes an electrodialysis unit, a dosing unit and an automatic control unit. The automatic control unit includes a PLC control module and a human-machine interface HMI. The electrodialysis unit includes an electrodialysis membrane stack 100 , a fresh water storage tank 200 , a concentrated water storage tank 300 and an extreme water storage tank 400 , and forms a dilute chamber circulation pipeline, a concentrated chamber circulation pipeline and an electrode chamber circulation pipeline.

[0040] The circulation pipeline of the fresh water chamber is as follows: the outlet water collection pipe 101 of the fresh water chamber of the electrodialysis membrane stack 100 is connected to the water inlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com