Anti-stripping agent for asphalt cold paving materials and preparation method of anti-stripping agent

An anti-stripping agent and cold patching technology, which is applied in the field of road engineering materials, can solve problems such as incomplete strength formation, asphalt and mineral material peeling, and reduce the adhesion performance of asphalt and stone materials, so as to improve the bonding performance and enhance the adhesion. The effect of improving the junction performance and improving the water resistance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The asphalt used is No. 70 A-grade road petroleum asphalt, the aggregate is limestone crushed stone, the filler is limestone powder, the diesel is commercially available No. 0 diesel oil, and the cold supplement is fatty acid ammonium cold supplement produced by Xi'an Bowang New Materials Co., Ltd. All other chemical reagents were commercially available.

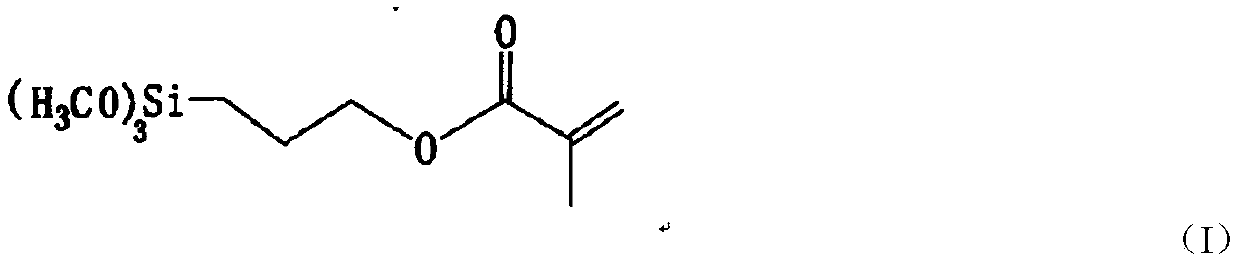

[0028] 1. Synthesize special cold tonic first

[0029] (1) Select and weigh trichlorosilane, allyl methacrylate, N,N'-di(2-naphthyl)-p-phenylenediamine in a molar ratio of 1:1.01:0.4, and mix trichlorosilane and N , N'-bis(2-naphthyl)-p-phenylenediamine is put into the reactor in proportion and stirred evenly, then titrate allyl methacrylate while stirring, the reaction temperature is 90°C, the titration time is 1h, after the titration is completed , the temperature was raised to 115° C., and the reaction was held for 0.5 h to obtain the product A.

[0030] (2) Put the product A into the reactor, add methanol dropwi...

Embodiment 2

[0044] The asphalt used is No. 70 A-grade road petroleum asphalt, the aggregate is limestone crushed stone, the filler is limestone powder, the diesel is commercially available No. 0 diesel oil, and the cold supplement is fatty acid ammonium cold supplement produced by Xi'an Bowang New Materials Co., Ltd. All other chemical reagents were commercially available.

[0045] 1. Synthesize special cold tonic first

[0046] (1) Select and weigh trichlorosilane, allyl methacrylate, N,N'-di(2-naphthyl)-p-phenylenediamine in a molar ratio of 1:1.005:0.6, and mix trichlorosilane and N , N'-bis(2-naphthyl)-p-phenylenediamine is put into the reactor according to the proportion and stirred evenly, then titrate allyl methacrylate while stirring, the reaction temperature is 100°C, the titration time is 1.3h, and the titration is completed Afterwards, the temperature was raised to 120° C., and the reaction was kept for 0.8 h to obtain the product A.

[0047] (2) Put the product A into the re...

Embodiment 3

[0061] The asphalt used is No. 70 A-grade road petroleum asphalt, the aggregate is limestone crushed stone, the filler is limestone powder, the diesel is commercially available No. 0 diesel, and the cold supplement is a fatty acid ammonium cold supplement produced by Xi'an Bowang New Materials Co., Ltd. All other chemical reagents were commercially available.

[0062] 1. Synthesize special cold tonic first

[0063] (1) Select and weigh trichlorosilane, allyl methacrylate, N,N'-di(2-naphthyl)-p-phenylenediamine in a molar ratio of 1:1.02:0.8, and mix trichlorosilane and N , N'-bis(2-naphthyl)-p-phenylenediamine is put into the reactor according to the proportion and stirred evenly, then titrate allyl methacrylate while stirring, the reaction temperature is 110°C, the titration time is 1.5h, and the titration is completed Afterwards, the temperature was raised to 125° C., and the reaction was kept for 1 h to obtain the product A.

[0064] (2) Put the product A into the reactor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com