Graphene/epoxy zinc powder heavy duty anticorrosion paint, and preparation method thereof

A technology of epoxy zinc and graphene, which is applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of easy agglomeration and dispersion stability of graphene, coating layering, expansion tanks, etc., and achieves simple and easy preparation methods control, excellent water resistance, and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] On the other hand, the embodiments of the present invention provide a method for preparing a graphene / zinc epoxy powder heavy-duty anti-corrosion coating, comprising the following steps:

[0039] S01. take each component according to the formula of above-mentioned graphene / zinc epoxy powder heavy anticorrosion coating;

[0040] S02. Evenly disperse the graphene, epoxy resin, dispersant, coupling agent, anti-sedimentation agent, and zinc powder in the formula of component A, and then perform grinding treatment to obtain a liquid slurry;

[0041] S03. Add stabilizers, fillers, and thickeners to the liquid slurry, continue grinding, and filter through 80-100 mesh gauze to obtain component A;

[0042] S04. Disperse the curing agent, epoxy resin, accelerator, and solvent formulated in component B to obtain component B.

[0043] In the preparation method of the graphene / epoxy zinc powder heavy-duty anti-corrosion coating provided by the embodiment of the present invention, c...

Embodiment 1

[0050] A kind of graphene / zinc epoxy powder heavy-duty anticorrosion paint, comprises A component and B component, wherein,

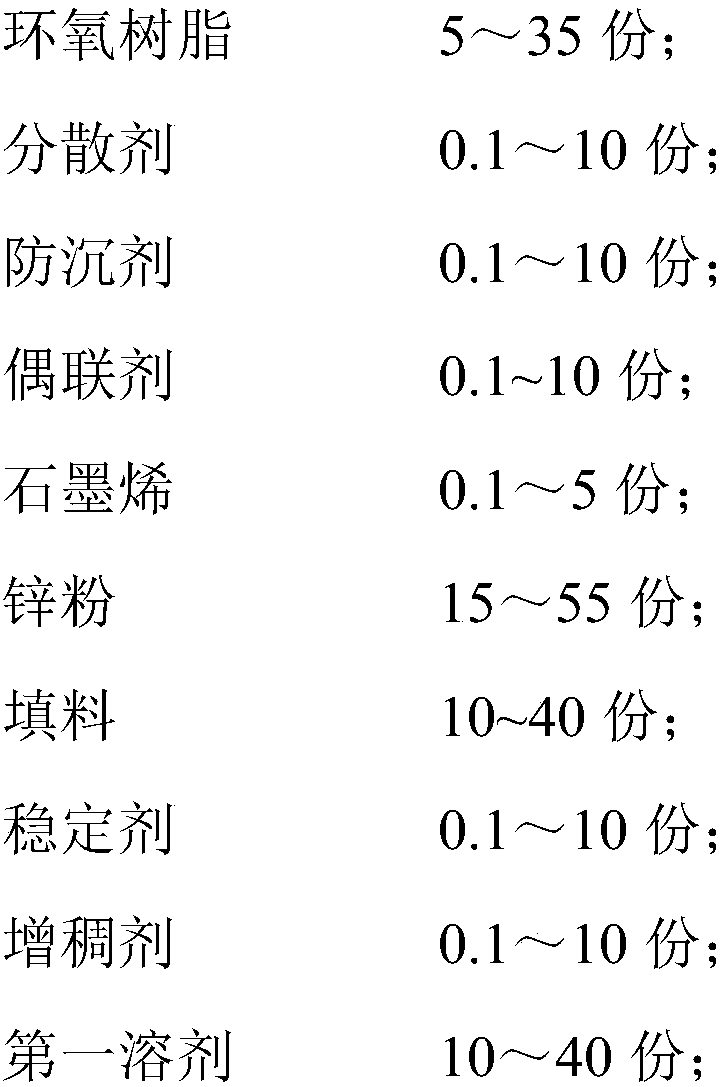

[0051] Described A component comprises the raw material component of following parts by weight:

[0052]

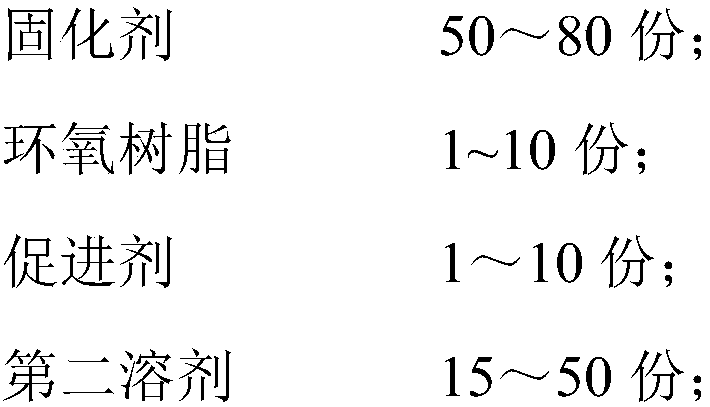

[0053] The B component includes the following raw material components in parts by weight:

[0054]

[0055]

[0056] The preparation method of described graphene / zinc epoxy powder heavy-duty anticorrosion coating, comprises the following steps:

[0057] Take each component according to the formula of above-mentioned graphene / epoxy zinc powder heavy-duty anticorrosion coating;

[0058] Put the graphene, epoxy resin, dispersant, coupling agent, anti-sedimentation agent, and zinc powder in the formula of A component into the container to disperse evenly; put the obtained liquid slurry into the sand mill for grinding, and the speed 3000r / min, time 50min;

[0059] Put the stabilizers, fillers, and thickeners formulated in component A into th...

Embodiment 2

[0063] A kind of graphene / zinc epoxy powder heavy-duty anticorrosion paint, comprises A component and B component, wherein,

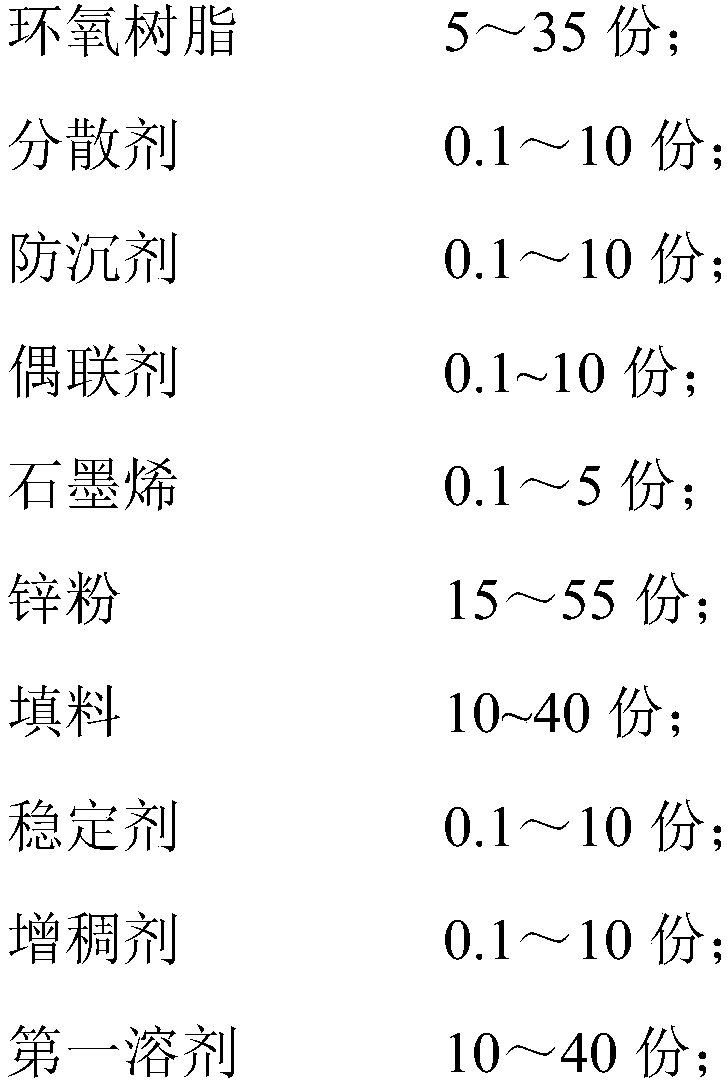

[0064] Described A component comprises the raw material component of following parts by weight:

[0065]

[0066] The B component includes the following raw material components in parts by weight:

[0067]

[0068] The preparation method of described graphene / zinc epoxy powder heavy-duty anticorrosion coating, comprises the following steps:

[0069] The preparation method of described graphene / zinc epoxy powder heavy-duty anticorrosion coating is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com