A treatment method for reducing heavy metal content in stainless steel table knives

A treatment method, stainless steel technology, applied in the field of reducing heavy metal content in stainless steel table knives, can solve the problems of excessive heavy metal content, endangering human health, and slow precipitation, etc., to reduce heavy metal content and improve antibacterial performance , Improve the effect of bacterial resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

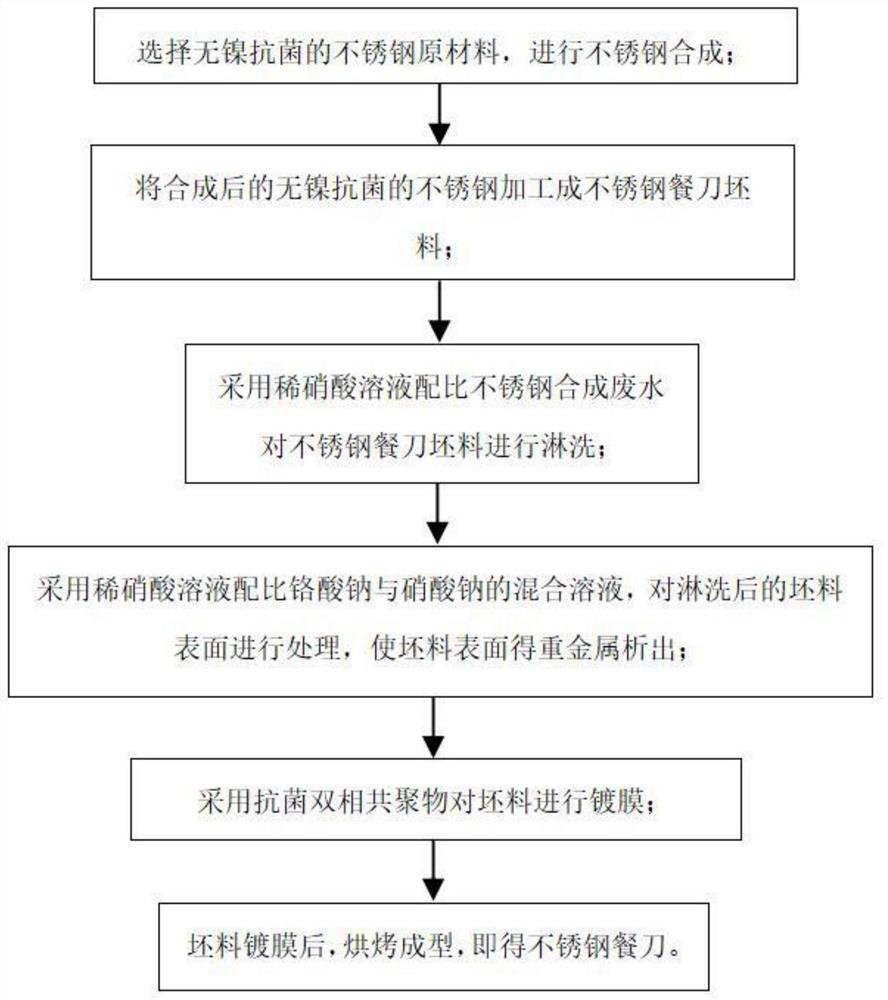

[0077] Such as figure 1 As shown, a kind of processing method that the present embodiment 1 provides reduces the heavy metal content in the stainless steel table knife, comprises the steps:

[0078] Step 1: Raw material selection

[0079] Select nickel-free antibacterial stainless steel raw materials for stainless steel synthesis;

[0080] The nickel-free antibacterial stainless steel raw material includes the following components by mass percentage:

[0081] C: 0.01%;

[0082] Si: 3.1%;

[0083] Mn: 1.00%;

[0084] S: 0.003%;

[0085] P: 0.02%;

[0086] Cr: 9.0%;

[0087] Mo: 0.8%;

[0088] W: 0.7%;

[0089] B: 0.08%;

[0090] Ag: 0.1%;

[0091] Cu: 4.0%;

[0092] Nb: 0.001%;

[0093] N: 0.6%;

[0094] Ba: 0.15%;

[0095] Rare earth: 0.01%;

[0096] Fe balance;

[0097] The rare earth is a lanthanide rare earth, and the content of La in the lanthanide rare earth is 60%.

[0098] Described stainless steel is synthesized, comprises the steps:

[0099] Step 11...

Embodiment 2

[0135] Such as figure 1 As shown, a kind of processing method that the present embodiment 2 provides reduces the heavy metal content in the stainless steel table knife, comprises the steps:

[0136] Step 1: Raw material selection

[0137] Select nickel-free antibacterial stainless steel raw materials for stainless steel synthesis;

[0138] The nickel-free antibacterial stainless steel raw material includes the following components by mass percentage:

[0139] C: 0.015%;

[0140] Si: 3.5%;

[0141] Mn: 2.00%;

[0142] S: 0.005%;

[0143] P: 0.025%;

[0144] Cr: 9.5%;

[0145] Mo: 1.3%;

[0146] W: 1.2%;

[0147] B: 0.13%;

[0148] Ag: 0.12%;

[0149] Cu: 4.5%;

[0150] Nb: 0.003%;

[0151] N: 0.7%;

[0152] Ba: 0.2%;

[0153] Rare earth: 0.1%;

[0154] Fe balance;

[0155] The rare earth is a lanthanide rare earth, and the content of La in the lanthanide rare earth is 65%.

[0156] Described stainless steel is synthesized, comprises the steps:

[0157] Step 11:...

Embodiment 3

[0193] Such as figure 1 As shown, a kind of processing method that the present embodiment 3 provides reduces the heavy metal content in the stainless steel table knife, comprises the steps:

[0194] Step 1: Raw material selection

[0195] Select nickel-free antibacterial stainless steel raw materials for stainless steel synthesis;

[0196] The nickel-free antibacterial stainless steel raw material includes the following components by mass percentage:

[0197] C: 0.02%;

[0198] Si: 3.9%;

[0199] Mn: 3.00%;

[0200] S: 0.006%;

[0201] P: 0.03%;

[0202] Cr: 10.0%;

[0203] Mo: 1.5%;

[0204] W: 1.5%;

[0205] B: 0.16%;

[0206] Ag: 0.13%;

[0207] Cu: 5.0%;

[0208] Nb: 0.05%;

[0209] N: 0.8%;

[0210] Ba: 0.3%;

[0211] Rare earth: 0.2%;

[0212] Fe balance;

[0213] The rare earth is a lanthanide rare earth, and the content of La in the lanthanide rare earth is 70%.

[0214] Described stainless steel is synthesized, comprises the steps:

[0215] Step 11:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com