Fiber containing compound functional microcapsule with removable shell

A composite function and microcapsule technology, which is applied in the field of fiber composite materials, can solve the problems of inability to resist ultraviolet rays, no removable shell material, and failure to perform as expected, so as to reduce energy consumption and equipment in the process Small modification, improve the effect of latent heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

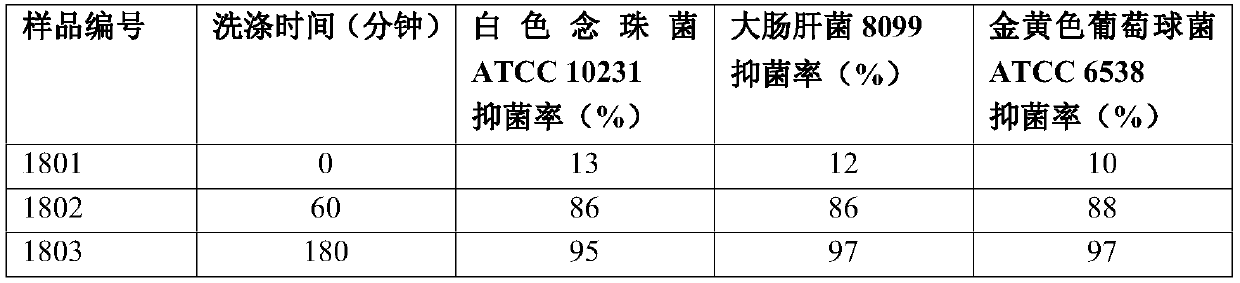

Embodiment 1

[0038] A kind of viscose fiber with antibacterial function and phase change temperature regulation function, its preparation process is:

[0039] A. Raise the temperature of n-octadecane to 40°C, after making it melt completely, add nano-zinc oxide with a particle size of 20-300nm as the second functional material, and mix evenly; wherein, the quality of the added nano-zinc oxide is positive 0.10-5.00% of octadecane mass;

[0040] B. Use the dispersion obtained in step A as the dispersed phase, and deionized water as the continuous phase to obtain an emulsion; wherein, the mass ratio of the dispersed phase to the continuous phase is 0.1-1.2, and the particle size of the emulsion is D90≦2.50 microns;

[0041] C. Add styrene to the emulsion described in step B, then add initiator benzoyl peroxide, heat up to 70° C., and keep warm for 5 hours to obtain a microcapsule suspension with both antibacterial and phase change temperature regulation composite functions; wherein, The qual...

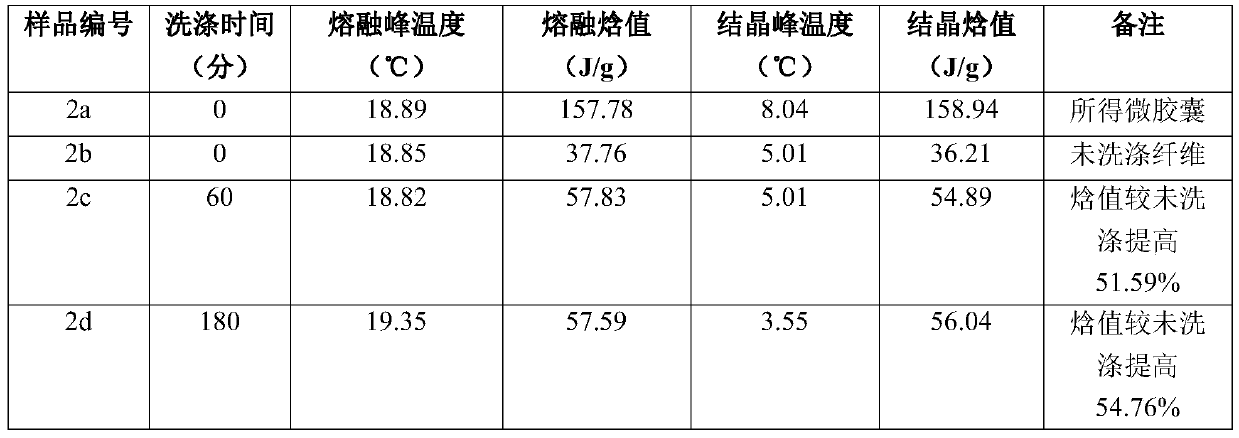

Embodiment 2

[0051] A lyocell fiber containing nano-calcium carbonate and having a phase-change temperature-regulating function, the preparation process of which is as follows:

[0052] A. Heat 20# paraffin wax to 40°C to melt it completely, then add nano-calcium carbonate with a particle size of 20-500nm as the second functional material, mix well, and then add styrene to form a dispersion; among them, add nano-calcium carbonate The quality of calcium carbonate is 0.10-3.50% of 20# paraffin wax quality; Wherein, the quality of described styrene is 5.00%-45.00% of dispersion liquid quality;

[0053] B. using the dispersion obtained in step A as the dispersed phase, the mixed solvent of water and ionic liquid 1-methyl-3-butylimidazolium chloride (wherein the amount of water is 15%, and the ionic liquid is the remainder) is the continuous phase, and the emulsion is obtained; Wherein, the mass ratio of the dispersed phase to the continuous phase is 0.1-1.2, and the particle size of the emulsi...

Embodiment 3

[0065] A kind of viscose fiber with antibacterial function and phase change temperature regulation function, its technical proposal is:

[0066] A. Select 58# paraffin as the heat-sensitive material, heat it up to 65°C, make it melt completely, add nano-zinc oxide with a particle size of 20-300nm as the second functional material, and mix evenly; among them, add nano-zinc oxide The quality of zinc is 0.10-5.00% of the 58# paraffin wax quality;

[0067] B. Use the dispersion obtained in step A as the dispersed phase, and deionized water as the continuous phase to obtain an emulsion; wherein, the mass ratio of the dispersed phase to the continuous phase is 0.1-1.2, and the particle size of the emulsion is D90≦2.50 microns;

[0068] C. Stir the above-mentioned emulsion evenly, slowly cool down to room temperature, make 58# paraffin solidify by cooling, form a shell material, and obtain the described microcapsule suspension with both antibacterial and phase change temperature regu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com