Method for preparing ganoderma lucidum extract

A technology of Ganoderma lucidum extract and Ganoderma lucidum, which is applied in the field of plant solid beverage production, can solve the problems of incomplete flavor retention, high pressure on environmental protection, poor practicability, etc., and achieve the effects of improving energy utilization rate, improving hygiene level and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

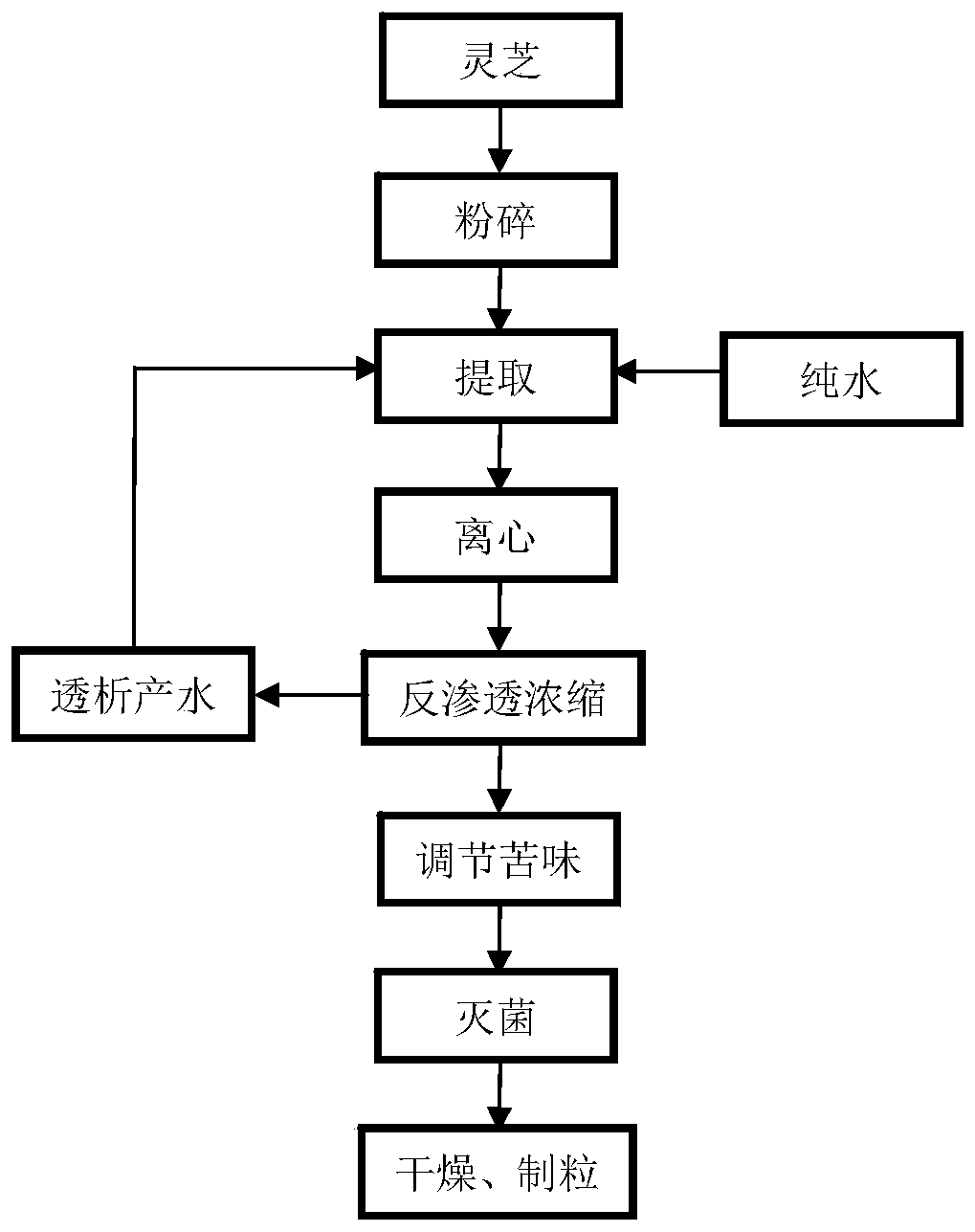

[0056] Such as figure 1 Shown, a kind of preparation method of Ganoderma lucidum extract comprises the following steps:

[0057] (1) Ganoderma lucidum crushed:

[0058] Ganoderma lucidum medicinal materials were first coarsely pulverized to 5 mesh with a pulverizer, and then rolled and pulverized to ultrafine powder, and the pulverization time was 30 minutes. The particle size distribution was determined by sampling as D90<43.5 μm.

[0059] (2) Extraction:

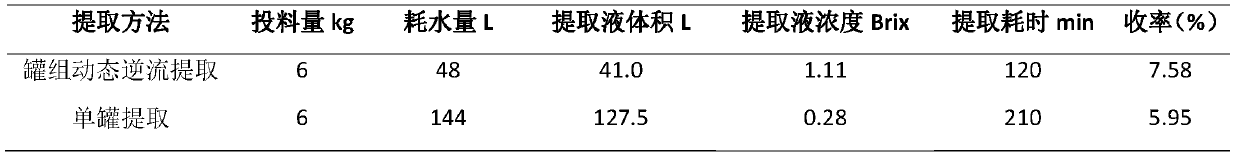

[0060] Tank group dynamic countercurrent extraction

[0061] Put 6.0kg of Ganoderma lucidum wall-breaking powder into the first, second and third stage tanks of the dynamic countercurrent tank group at a rate of 2kg per can, add 28.0L pure water to the first stage tank, raise the temperature to 85°C, and cycle for 20 minutes; then the first stage tank Extract the extract to the secondary tank as the extraction solvent, heat up to 85°C, and the cycle time is 20 minutes; continue to pump the extract from the secondary ta...

Embodiment 2

[0077] Such as figure 1 Shown, a kind of preparation method of Ganoderma lucidum extract comprises the following steps:

[0078] (1) Ganoderma lucidum crushed:

[0079] Ganoderma lucidum fruiting bodies are coarsely pulverized to 15 mesh with a pulverizer, and then crushed to ultrafine powder by low-temperature rolling. The pulverization time is 60 minutes, and the particle size distribution D90<45.0 μm.

[0080] (2) Extraction:

[0081] Put 9.0kg of Ganoderma lucidum wall-breaking powder into the first, second and third stage tanks of the dynamic countercurrent tank group according to 3kg, 3kg, and 3kg respectively. ℃, cycle for 30 minutes; then use the extract of the first tank as the extraction solvent of the second tank, heat up to 95 °C, and circulate for 30 min; continue to use the extract of the second tank as the extraction solvent of the third tank and heat to 95 °C , circulated for 30 minutes, the extract was filtered through the plate and frame, and the extract w...

Embodiment 3

[0093] Such as figure 1 Shown, a kind of preparation method of Ganoderma lucidum extract comprises the following steps:

[0094] (1) Ganoderma lucidum crushed:

[0095] Ganoderma lucidum fruiting bodies are coarsely pulverized to 20 mesh with a pulverizer, and then crushed to ultrafine powder by low-temperature rolling. The pulverization time is 45 minutes, and the particle size distribution D90<45.0 μm.

[0096] (2) Extraction:

[0097] Put 6.0kg of Ganoderma lucidum wall-breaking powder into the first, second and third stage tanks of the dynamic countercurrent tank group according to 2kg, 2kg and 2kg per can respectively, add 28.0L pure water and 2.0L centrifugal dialysis water to the first level tank, and raise the temperature to 90°C , circulate for 25 minutes; then use the extract from the first-stage tank as the extraction solvent of the second-stage tank, heat up to 85°C, and circulate for 25 minutes; continue to use the extract from the second-stage tank as the extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com