Preparation method of spherical nano-strontium carbonate

A nano-carbonic acid and spherical technology, applied in the direction of strontium carbonate, calcium carbonate/strontium/barium, nanotechnology, etc., can solve the problems of low-end supply capacity excess, irregular strontium industry, structural imbalance, etc., and achieve uniform and spherical particles Good, narrow particle size range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

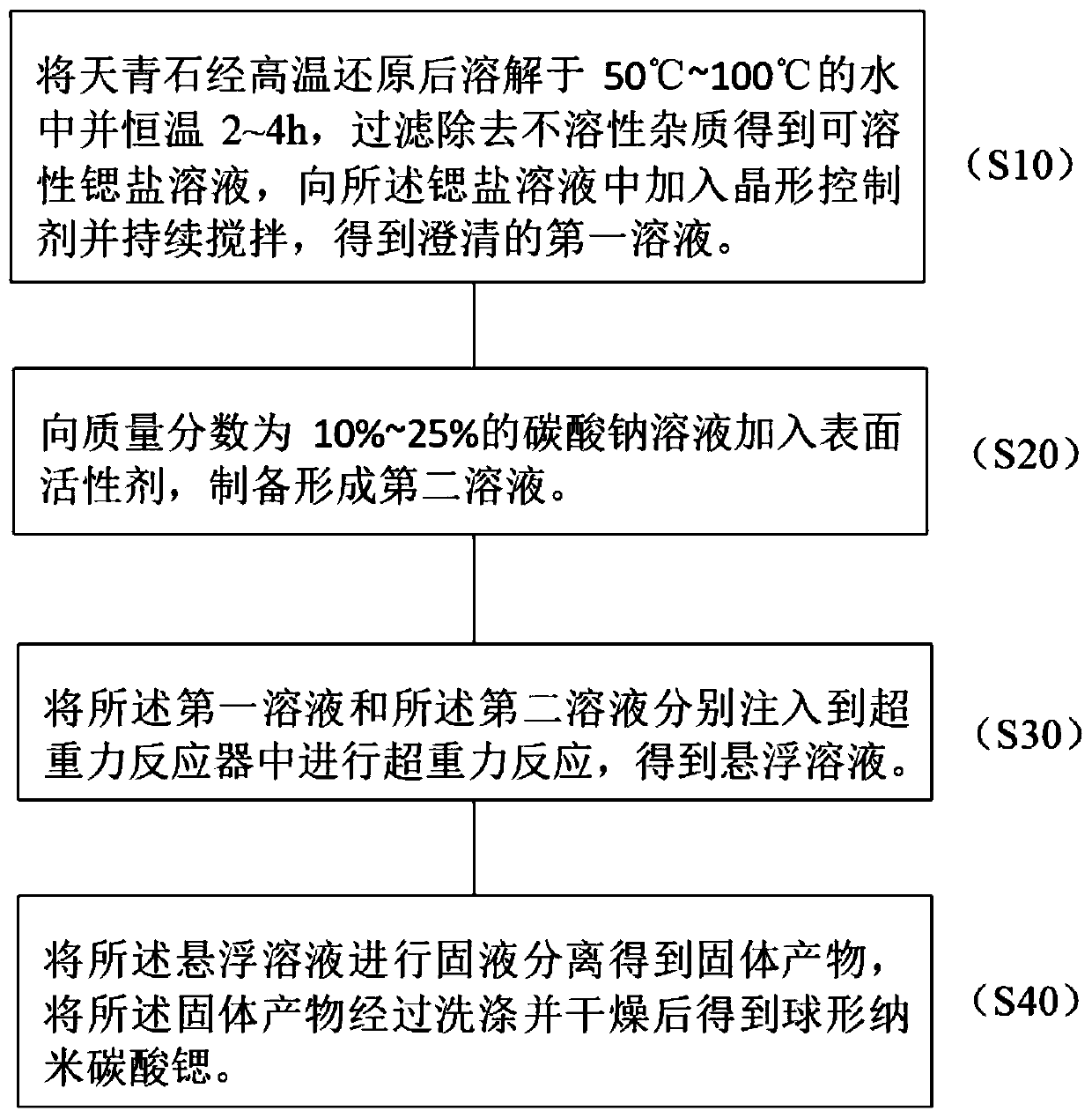

[0025] The invention provides a method for preparing spherical nano-strontium carbonate, see figure 1 , the preparation method comprises the steps of:

[0026] S10. After high-temperature reduction, celestite is dissolved in water at 50° C. to 100° C. and kept at a constant temperature for 2 to 4 hours, and filtered to remove insoluble impurities to obtain a soluble strontium salt solution. Add a crystal form control agent to the strontium salt solution and continue stirring to obtain Clear first solution.

[0027] Specifically, the crystal form control agent is disodium ethylenediaminetetraacetate (EDTA). The molar ratio of the added amount of the crystal form control agent to the strontium ion in the strontium salt solution is 0.4-1.

[0028] S20. Adding a surfactant to the sodium carbonate solution with a mass fraction of 10% to 25% to prepare a second solution.

[0029] Specifically, the surfactant is selected to be cetyltrimethylammonium bromide (CTMAB). The added amo...

Embodiment 1

[0035] (1), dissolve lapis lazuli in water at 85°C after high-temperature reduction and keep it warm for 2 hours to remove insoluble impurities, and add a crystal form control agent (disodium ethylenediaminetetraacetate) to the strontium salt solution at 85°C ), the molar ratio of the amount of the crystal form control agent to the strontium ion in the strontium salt solution is 0.6, and the stirring is continued and mixed to obtain a clear first solution.

[0036] (2), in the sodium carbonate solution that mass fraction is 15%, add cetyl trimethyl ammonium bromide, the cetyl trimethyl ammonium bromide amount that adds is 0.7% of sodium carbonate quality, prepares and forms second solution.

[0037] (3) The first solution and the second solution are respectively injected into a high gravity reactor to carry out a high gravity reaction to obtain a slurry solution. Wherein, the injection flow rate of the first solution is controlled to be 85L / h, the injection flow rate of the s...

Embodiment 2

[0041] (1), dissolve lapis lazuli in water at 95°C after high-temperature reduction and keep it warm for 3.5 hours to remove insoluble impurities, and add a crystal form control agent (disodium ethylenediaminetetraacetate) to the strontium salt solution at 95°C ), the molar ratio of the addition amount of the crystal form control agent to the strontium ion in the strontium salt solution is 1, and the stirring is continued and uniformly mixed to obtain a clear first solution.

[0042] (2), in the sodium carbonate solution that mass fraction is 25%, add cetyl trimethyl ammonium bromide, the cetyl trimethyl ammonium bromide amount that adds is 1% of the quality of sodium carbonate, prepares and forms second solution.

[0043] (3) The first solution and the second solution are respectively injected into a high gravity reactor to carry out a high gravity reaction to obtain a suspension solution. Wherein, the injection flow rate of the first solution is controlled to be 110 L / h, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com