Green preparation method and application of spiny spherical TiO2

A thorn-like, green technology, applied in chemical instruments and methods, photosensitive equipment, titanium oxide/hydroxide, etc., can solve problems such as lack of important synthesis methods, improve photoelectric conversion performance, reduce process costs, and simplify the preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: A kind of prickly spherical TiO 2 The preparation method, the steps are as follows:

[0026] (1) Measure 67ml of absolute ethanol in a 200ml beaker to obtain solution A, and put the above solution in an ice-water bath;

[0027] (2) Measure 6ml of titanium tetrachloride solution, add it dropwise to solution A, stir for 5 minutes, add 67ml of secondary water and continue stirring for 10 minutes, and finally get a light yellow titanium tetrachloride solution (solution B);

[0028] (3) Add solution B into a 200ml beaker and react at 80°C for 2 hours to obtain a milky white homogeneous aqueous solution (solution C);

[0029] (4) Put the solution C in the beaker for 4 months, and after centrifugation, washing and drying, TiO 2 .

Embodiment 2

[0030] Embodiment 2: A kind of prickly spherical TiO 2 The green preparation method, the steps are as follows:

[0031] (1) Measure 20ml of absolute ethanol in a 200ml beaker to obtain solution A, and put the above solution in an ice-water bath;

[0032] (2) Measure 20ml of titanium tetrachloride solution, add it dropwise to solution A, stir for 5 minutes, add 114ml of secondary water and continue stirring for 10 minutes, and finally get a light yellow titanium tetrachloride solution (solution B) ;

[0033] (3) Add solution B into a 200ml beaker and react at 80°C for 1 hour to obtain a milky white homogeneous aqueous solution (solution C);

[0034] (4) Put the solution C in the beaker for 4 months, and after centrifugation, washing and drying, TiO 2 .

Embodiment 3

[0035] Embodiment 3: a kind of thorn ball TiO 2 The green preparation method, the steps are as follows:

[0036] (1) Measure 100ml of absolute ethanol in a 200ml beaker to obtain solution A, and put the above solution in an ice-water bath;

[0037] (2) Measure 6ml of titanium tetrachloride solution, add it dropwise to solution A, stir for 5 minutes, add 240ml of secondary water and continue stirring for 10 minutes, and finally obtain a light yellow titanium tetrachloride solution (solution B);

[0038] (3) Add solution B into a 200ml beaker and react at 80°C for 3 hours to obtain a milky white homogeneous aqueous solution (solution C);

[0039] (4) Put the solution C in the beaker for 4 months, and after centrifugation, washing and drying, TiO with the shape of spiny balls can be obtained. 2 .

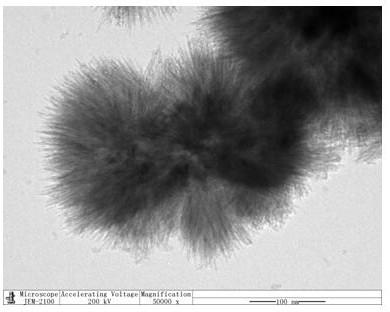

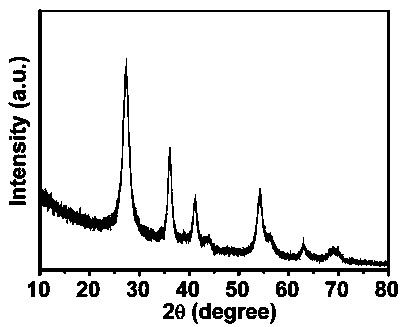

[0040] Depend on figure 1 It can be seen that the TiO designed in the present invention 2 It has the characteristics of a three-dimensional structure, and its particle size is abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com