Synthesis method of silicone fluoride-free water-proofing agent modified with polyurethane and acrylic acid and water-proofing agent

A technology of polyurethane acrylic and fluorine-free water repellent, which is applied in the direction of improved hand-feeling fibers, liquid-repelling fibers, textiles and papermaking, etc. It can solve problems such as hardening and inconspicuous improvement in durability, and achieve selectivity improvement, Excellent waterproof effect, good hand feeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

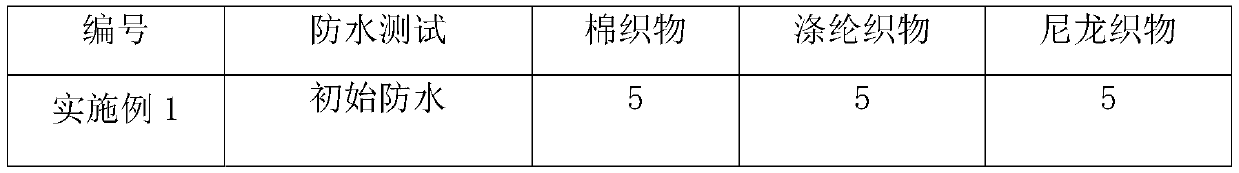

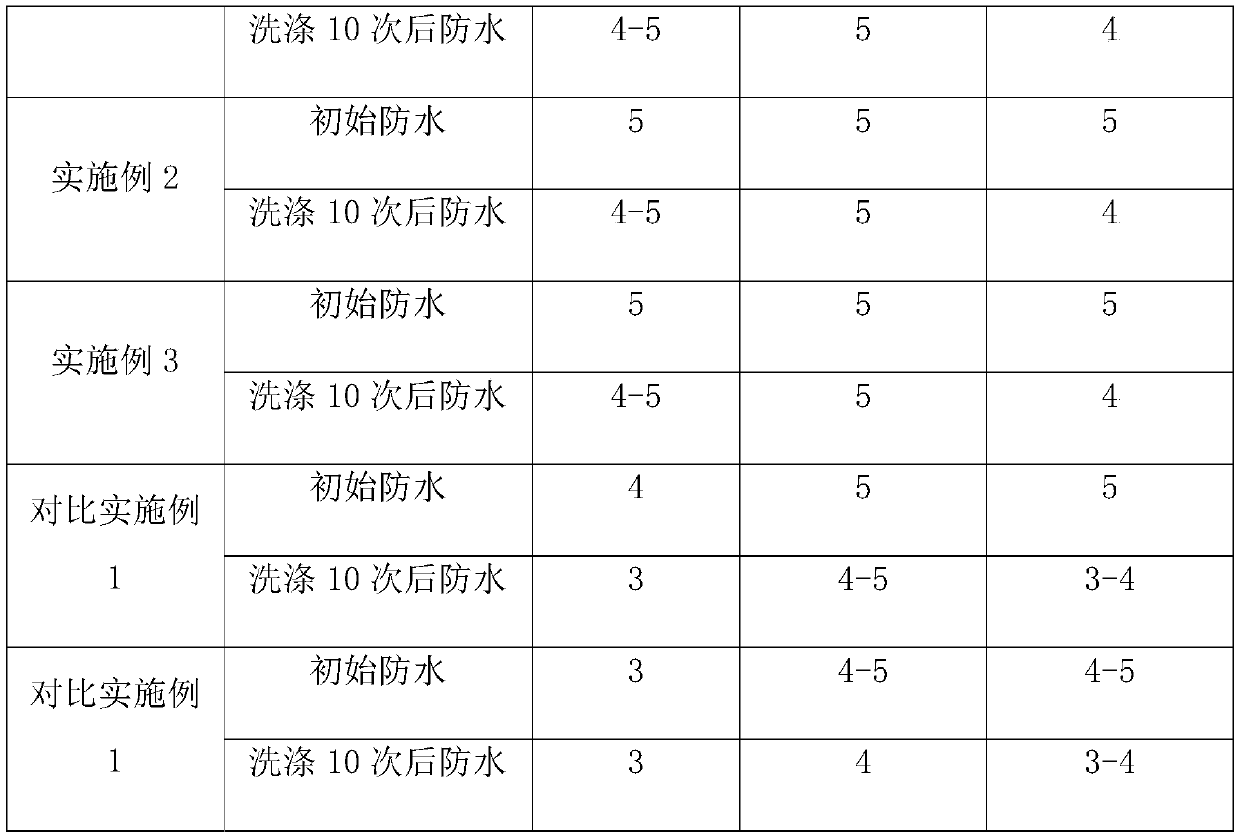

Examples

Embodiment 1

[0035] Synthesis of single-ended aminoalkyl silicone: (1) 6.41 parts (parts by mass, the same below) of n-butyllithium and 70 parts of toluene are prepared into a solution; 289.2 parts of hexamethylcyclotrisiloxane are added and dissolved in an equal mass of toluene Then add 290 parts of tetrahydrofuran, and react for 6 hours at 30°C; then add 10 parts of dimethyl monochlorosilane, and react for 1 hour at 30°C; filter, and remove the low boilers under reduced pressure to obtain mono Hydrogen-terminated polydimethylsiloxane, yield 98%; (2) 500 parts of toluene, 9.2 parts of allyl chloride, 0.01 part of isopropanol solution of chloroplatinic acid (chloroplatinic acid concentration 2%), heat up 100 ℃, add 300.8 parts of single-ended hydrogen polydimethylsiloxane dropwise; after adding, react at 100℃ for 8 hours; remove low boilers and unreacted substances under reduced pressure to obtain chloropropyl-terminated polysiloxane with a yield of 96% (3) 308.6 parts of chloropropyl-term...

Embodiment 2

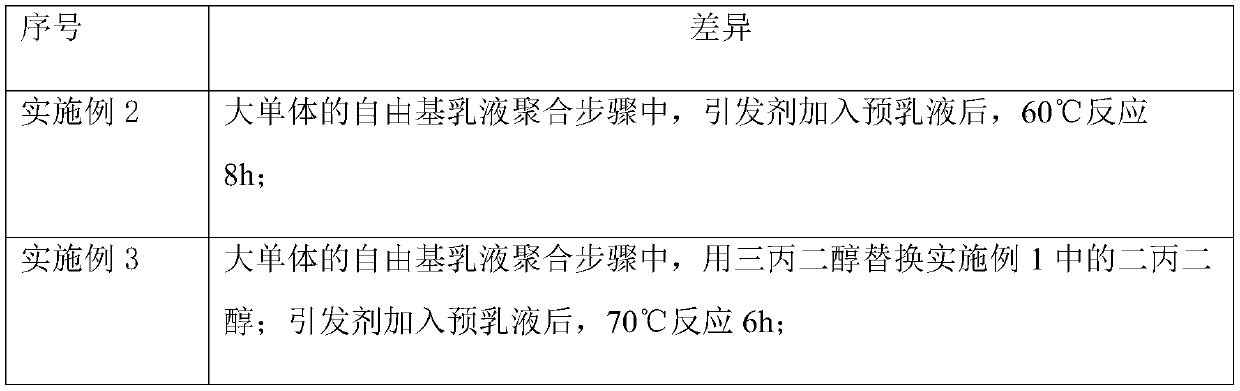

[0040] Embodiment 2 and embodiment 3 all are on the basis of embodiment 1 to make fine-tuning to formula or process, and the place that two embodiments differ from embodiment 1 are listed below in the form of attached table:

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com