Convex hot-melt marking line and preparation method thereof

A hot-melt and marking technology, applied in the field of marking, can solve the problems of wear resistance, poor film-forming stability, and marking lines that cannot meet the needs of use, etc., to achieve reduced entanglement, increased fluidity, and enhanced durability. The effect of grinding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

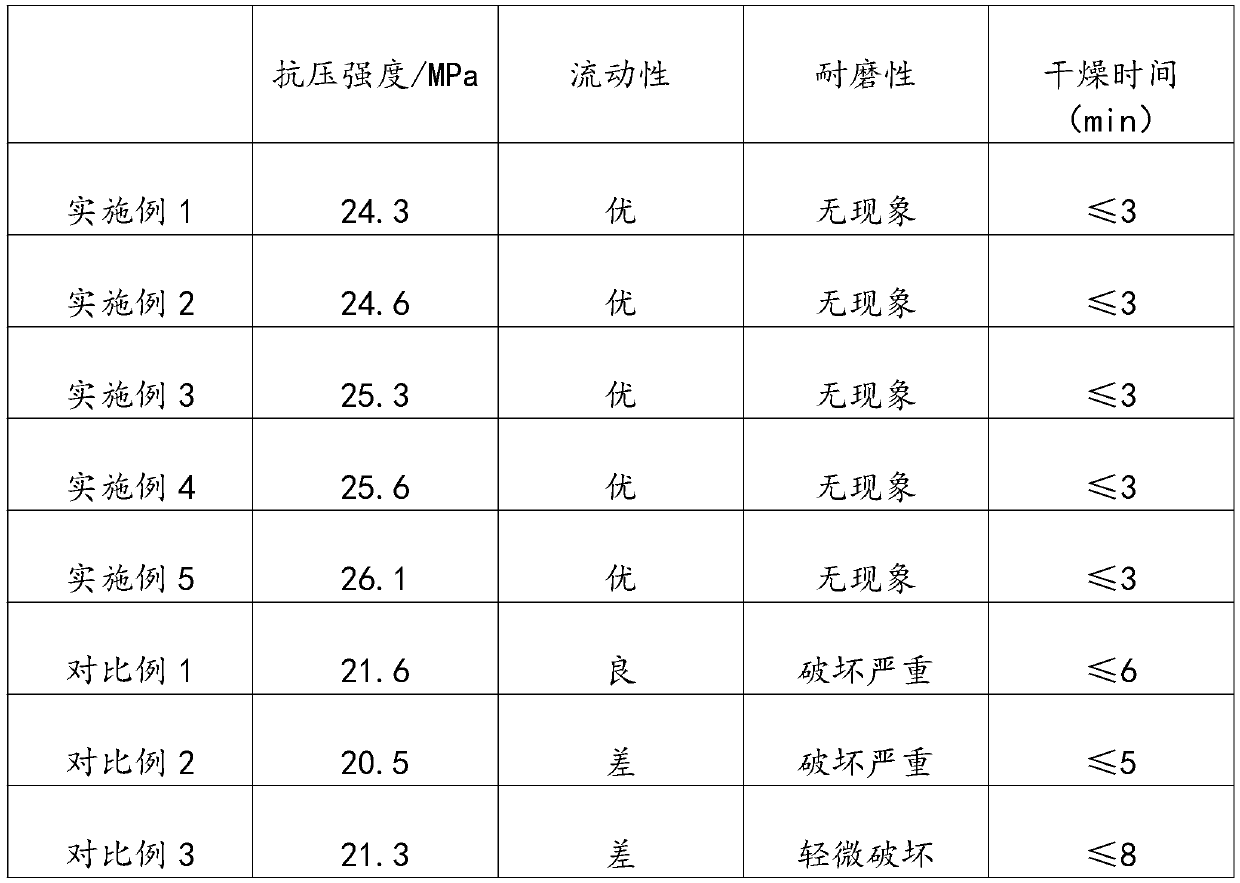

Examples

Embodiment 1

[0032] Raised hot-melt marking line, made of the following raw materials by weight: 10 parts of modified C5 petroleum resin, 5 parts of polyurethane, 30 parts of glass beads, 30 parts of nano-silica, 10 parts of calcium carbonate, 10 parts of titanium dioxide, 3 parts polypropylene wax, 2 parts stearic acid, 1 part glyceryl stearate, 1 part polydimethylsiloxane, 2 parts dioctyl terephthalate;

[0033] The raised hot-melt marking line is made by the following methods:

[0034] Step S1, mixing polypropylene wax, stearic acid and glyceryl stearate, heating to 120°C, stirring at a constant speed for 15 minutes, cooling, grinding and pulverizing, passing through a 200-300 mesh sieve to obtain a compound additive;

[0035]Step S2, mixing and grinding nano-silica, calcium carbonate, polyurethane, dioctyl terephthalate and titanium dioxide, then adding modified C5 petroleum resin, compounding additives and polydimethylsiloxane and heating to 70°C , to prepare a mixture;

[0036] Ste...

Embodiment 2

[0042] Raised hot-melt marking line, made of the following raw materials by weight: 12 parts of modified C5 petroleum resin, 6 parts of polyurethane, 33 parts of glass beads, 32 parts of nano-silica, 12 parts of calcium carbonate, 12 parts of titanium dioxide, 3 parts polypropylene wax, 2 parts stearic acid, 1 part glyceryl stearate, 1 part polydimethylsiloxane, 2 parts dioctyl terephthalate;

[0043] The raised hot-melt marking line is made by the following methods:

[0044] Step S1, mixing polypropylene wax, stearic acid and glyceryl stearate, heating to 120°C, stirring at a constant speed for 15 minutes, cooling, grinding and pulverizing, passing through a 200-300 mesh sieve to obtain a compound additive;

[0045] Step S2, mixing and grinding nano-silica, calcium carbonate, polyurethane, dioctyl terephthalate and titanium dioxide, then adding modified C5 petroleum resin, compounding additives and polydimethylsiloxane and heating to 70°C , to prepare a mixture;

[0046] St...

Embodiment 3

[0048] Raised hot-melt marking line, made of the following raw materials by weight: 14 parts of modified C5 petroleum resin, 8 parts of polyurethane, 40 parts of glass beads, 35 parts of nano-silica, 13 parts of calcium carbonate, 13 parts of titanium dioxide, 4 parts of polypropylene wax, 2 parts of stearic acid, 1 part of glyceryl stearate, 1 part of polydimethylsiloxane, 4 parts of dioctyl terephthalate;

[0049] The raised hot-melt marking line is made by the following methods:

[0050] Step S1, mix polypropylene wax, stearic acid and glyceryl stearate, heat to 120°C until it becomes completely liquid, stir at a constant speed for 15 minutes, cool, grind and pulverize, and pass through a 200-300 mesh sieve to obtain a composite Auxiliary;

[0051] Step S2, mixing and grinding nano-silica, calcium carbonate, polyurethane, dioctyl terephthalate and titanium dioxide, then adding modified C5 petroleum resin, compounding additives and polydimethylsiloxane and heating to 70°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com