Textile surface adhesive staining nuclide detergent and preparation method thereof

A technology of surfactants and composite surfactants, applied in the direction of surface active detergent compositions, non-ionic surface active compounds, chemical instruments and methods, etc., can solve the problems of high price, single product, long delivery cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

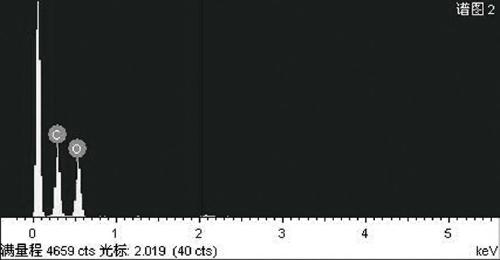

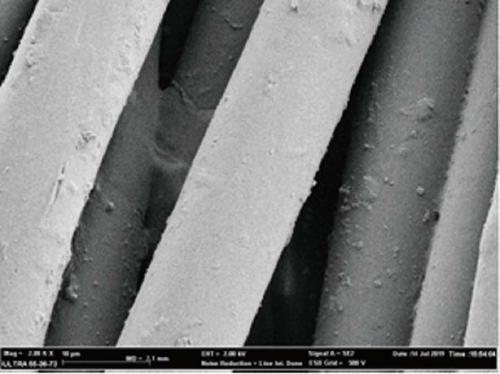

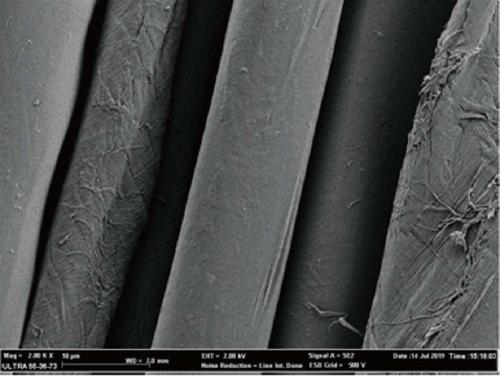

Image

Examples

Embodiment 1

[0040] A textile surface adhesive nuclide decontamination agent and a preparation method thereof are made of the following raw materials: 35 g of propylene glycol block polyether, 85 g of fatty alcohol polyoxyethylene ether AEO-9, 20 g of fatty alcohol ether sodium sulfate, Fatty alcohol polyoxyethylene ether carboxylic acid 5g, alkylbenzenesulfonic acid 5g, trisodium methyl glycine diacetate 50g, diethylenetriaminepentaacetic acid 50g, sodium iminodisuccinate 100g, protease 95g, lipase 5g, boric acid 60g, trehalose 15g, deionized water 475g.

[0041] Use potassium hydroxide or citric acid to adjust the pH value to 9.0, dilute this example with deionized water to a content of 5 g / L, and stir for 45 minutes at 50°C to decontaminate. The decontamination test results are shown in Attached Table 1.

Embodiment 2

[0043] A textile surface adhesive nuclide decontamination agent and a preparation method thereof, which are made of the following raw materials: 35g of propylene glycol block polyether, 90g of fatty alcohol polyoxyethylene ether AEO-9, 35g of fatty alcohol ether sodium sulfate, Fatty alcohol polyoxyethylene ether carboxylic acid 5g, alkylbenzenesulfonic acid 10g, trisodium methylglycine diacetate 40g, diethylenetriaminepentaacetic acid 40g, sodium iminodisuccinate 70g, protease 80g, lipase 40g, boric acid 40g, trehalose 10g, deionized water 505g.

[0044] Use potassium hydroxide or citric acid to adjust the pH value to 9.2, dilute the sample with deionized water to a content of 5 g / L, and stir for 45 minutes at 50°C to decontaminate. The decontamination test results are shown in Attached Table 1.

Embodiment 3

[0046] A textile surface adhesive nuclide decontamination agent and a preparation method thereof, made of the following raw materials, 25g of propylene glycol block polyether, 70g of fatty alcohol polyoxyethylene ether AEO-9, 10g of fatty alcohol ether sodium sulfate, Fatty alcohol polyoxyethylene ether carboxylic acid 20g, alkylbenzenesulfonic acid 10g, trisodium methylglycine diacetate 45g, diethylenetriaminepentaacetic acid 45g, sodium iminodisuccinate 50g, protease 40g, lipase 100g, boric acid 50g, trehalose 12.5g, deionized water 522.5g.

[0047] Use potassium hydroxide or citric acid to adjust the pH value to 9.5. Dilute this example with deionized water to a content of 5 g / L, decontaminate at 50°C for 45 minutes, see attached table 1 for the decontamination test results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com