Method for preparing organic flexible screen substrate material

A substrate material and flexible screen technology, applied in the field of OLED, can solve the problems of large fluctuations in production costs, threats to human health, poor market stability, etc., and achieve good thermal stability, excellent dimensional variability and anti-yellowing properties. , the effect of improving the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

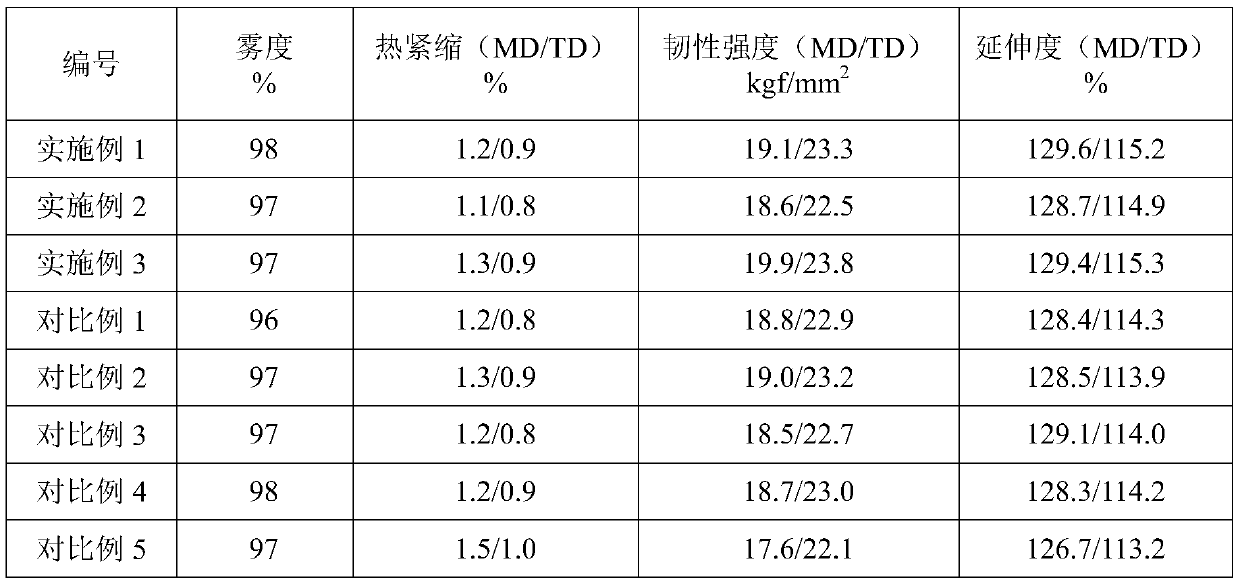

Embodiment 1

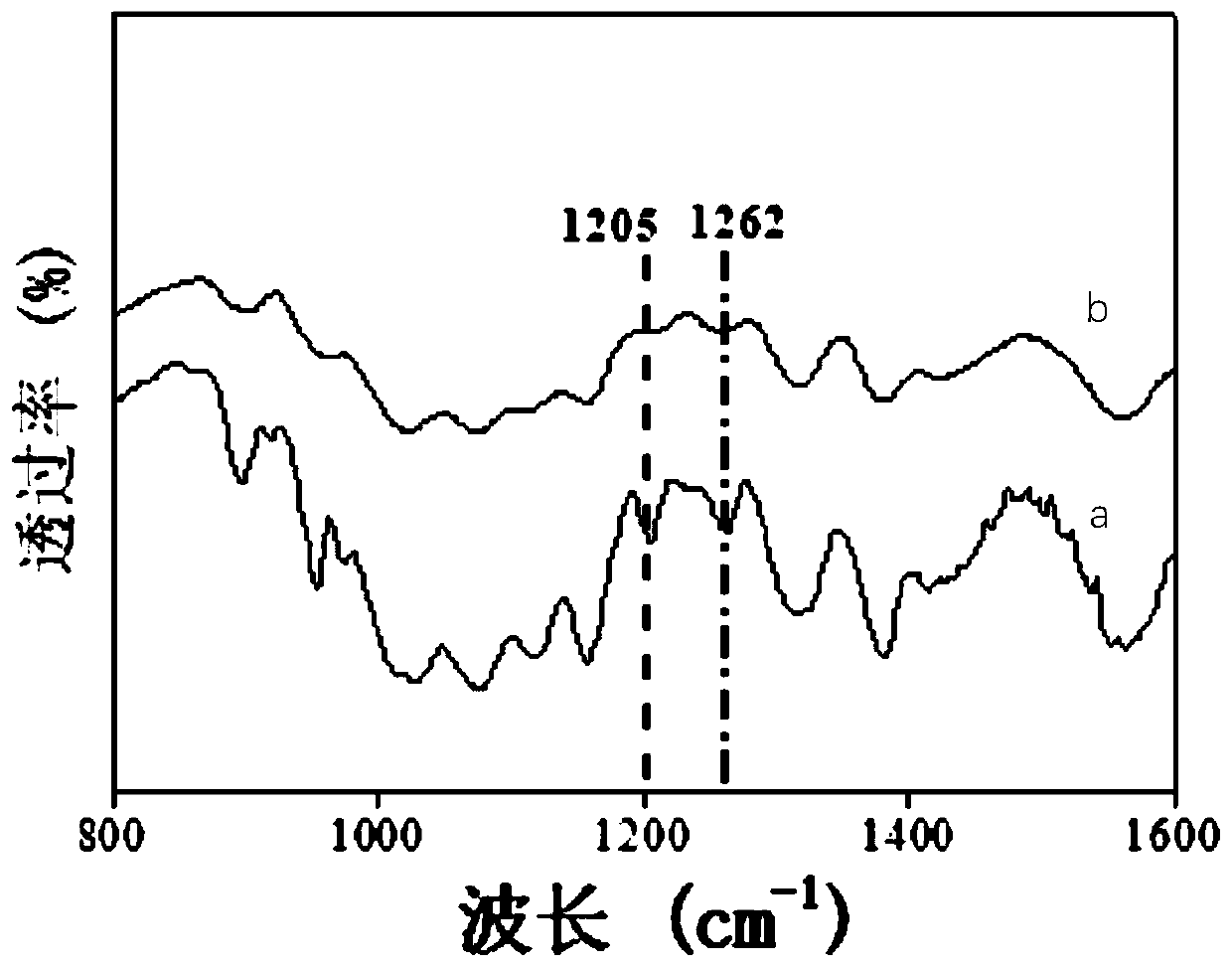

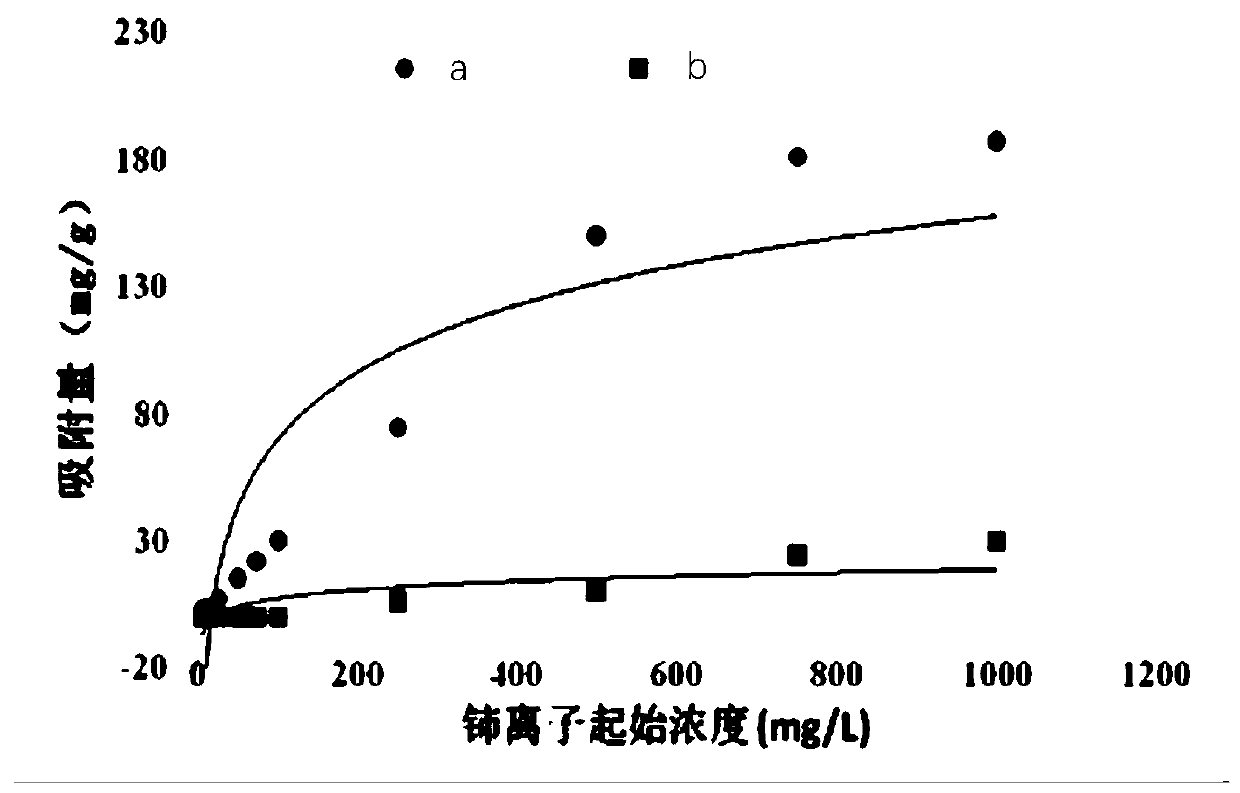

[0031] Dry the Portunus crab shells to constant weight, boil them with 5% NaOH (w:v) for 2 hours, repeat 3 times, filter with neutral filter paper, and obtain the filter residue; transfer the filter residue to 2mol / L nitric acid solution, soak for 10h, repeat After 3 times, filter with neutral filter paper, and wash the filter residue with deionized water until neutral. The filter residue was transferred to DPTA aqueous solution (15%, m / v) (filter residue: solution = 1 (g): 20 (mL)), and N,N-dimethylformamide (3%, v / v) was added successively, followed by Oxidize hydrogen (2%, v / v), adjust the pH value of the solution to alkaline (pH=11), stir continuously at room temperature for 2 days, filter with neutral filter paper, and wash the filter residue with deionized water until neutral. The cleaned filter residue was transferred to an acetic acid solution with pH=3, ultrasonicated (900W, 50Hz, ice bath, 30min); after ultrasonication, centrifuged (12000rpm, 4°C, 30min), the superna...

Embodiment 2

[0033] Dry the Portunus crab shells to constant weight, boil them with 8% NaOH (w:v) for 1 hour, repeat 4 times, filter with neutral filter paper, and obtain the filter residue; transfer the filter residue to 1mol / L nitric acid solution, soak for 11h, repeat After 4 times, filter with neutral filter paper, and wash the filter residue with deionized water until neutral. The filter residue was transferred to DPTA aqueous solution (5%, m / v) (filter residue: solution = 1 (g): 30 (mL)), and N,N-dimethylformamide (1%, v / v) was added successively, followed by Oxidize hydrogen (1%, v / v), adjust the pH of the solution to alkaline (pH=9), stir continuously at room temperature for 1 day, filter with neutral filter paper, and wash the filter residue with deionized water until neutral. The cleaned filter residue was transferred to an acetic acid solution with pH=2.5, ultrasonicated (800W, 40Hz, 4°C water bath, 40min); after ultrasonication, centrifuged (10000rpm, 0°C, 40min), the supernata...

Embodiment 3

[0035]Dry the Portunus crab shells to constant weight, boil them with 10% NaOH (w:v) for 3 hours, repeat twice, filter with neutral filter paper, and obtain the filter residue; transfer the filter residue to 3mol / L nitric acid solution, soak for 12h, repeat After 2 times, filter with neutral filter paper, and wash the filter residue with deionized water until neutral. The filter residue was transferred to DPTA aqueous solution (10%, m / v) (filter residue: solution = 1 (g): 10 (mL)), and N,N-dimethylformamide (5%, v / v) was added successively, followed by Oxidize hydrogen (3%, v / v), adjust the pH of the solution to alkaline (pH=13), stir continuously at room temperature for 3 days, filter with neutral filter paper, and wash the filter residue with deionized water until neutral. The washed filter residue was transferred to an acetic acid solution with pH=3.5, ultrasonicated (1000W, 60Hz, 2°C water bath, 20min); after ultrasonication, centrifuged (14000rpm, 2°C, 20min), the superna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com