Reactor, reaction system and phenolic wastewater treatment method based on supercritical water oxidation

一种超临界水氧化、反应器的技术,应用在氧化水/污水处理、水/污水处理、化学仪器和方法等方向,能够解决有机废水难以实现反应自热、系统高能耗输入、腐蚀结垢过热等问题,达到保证稳定和可靠、实现自热、加速氧化降解的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] In this embodiment, waste water containing phenol is selected, and the emission standard of phenol after the system treatment of the present application is required to be lower than 0.5 mg / L.

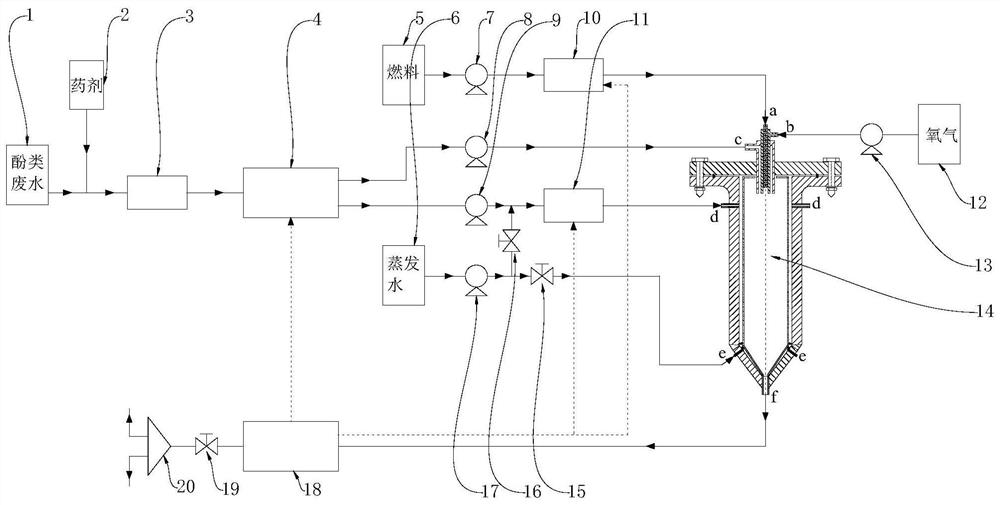

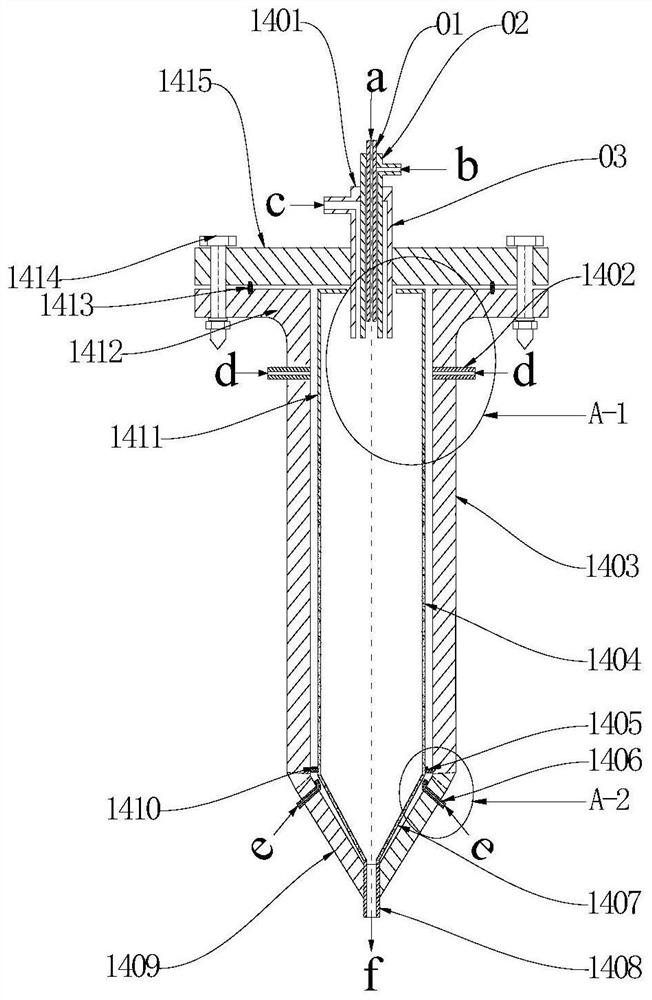

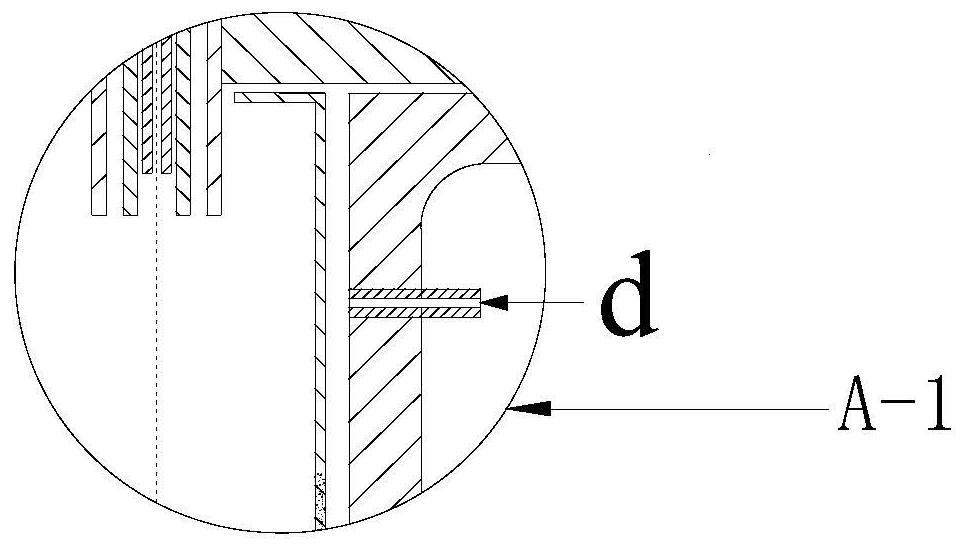

[0063] Such as figure 1 The reaction system based on supercritical water oxidation of the present invention shown includes: waste water branch, fuel branch, evaporated water branch, oxygen branch and reactor 14;

[0064] The waste water branch includes a waste water pool 1, a pretreatment device 3, and a concentration system 4 connected in sequence; the concentrated waste liquid outlet of the concentration system 4 is connected to the concentrated waste water inlet c of the reactor 14; the fuel branch is passed through After the first heat exchange device 10, it is connected to the fuel inlet a of the reactor 14;

[0065] The evaporating water branch includes an evaporating water tank 6. After the outlet of the evaporating water tank 6 is pressurized by an evaporating water pump...

Embodiment 2

[0102] In this embodiment, waste water containing phenol is selected, and the emission standard of phenol after the system treatment of the present application is required to be lower than 0.5 mg / L. In the phenol-containing wastewater treatment process of the present embodiment, the added alkaline agent is sodium carbonate.

[0103] The difference between this embodiment and the treatment system of Embodiment 1 is that the concentration system 4 and the energy recovery device 18 are arranged in different ways.

[0104] Such as Figure 6 As shown, the concentration system 4 of this embodiment includes: a wastewater booster pump 0042 and a reverse osmosis membrane module 0043 connected in sequence. The energy recovery device 18 includes a first heat exchanger 1801 and a pressure energy recovery device 1804 connected in sequence; the pressure energy recovery device 1804 is arranged on the pipeline between the wastewater booster pump 0042 and the pretreatment device 3 .

[0105]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com