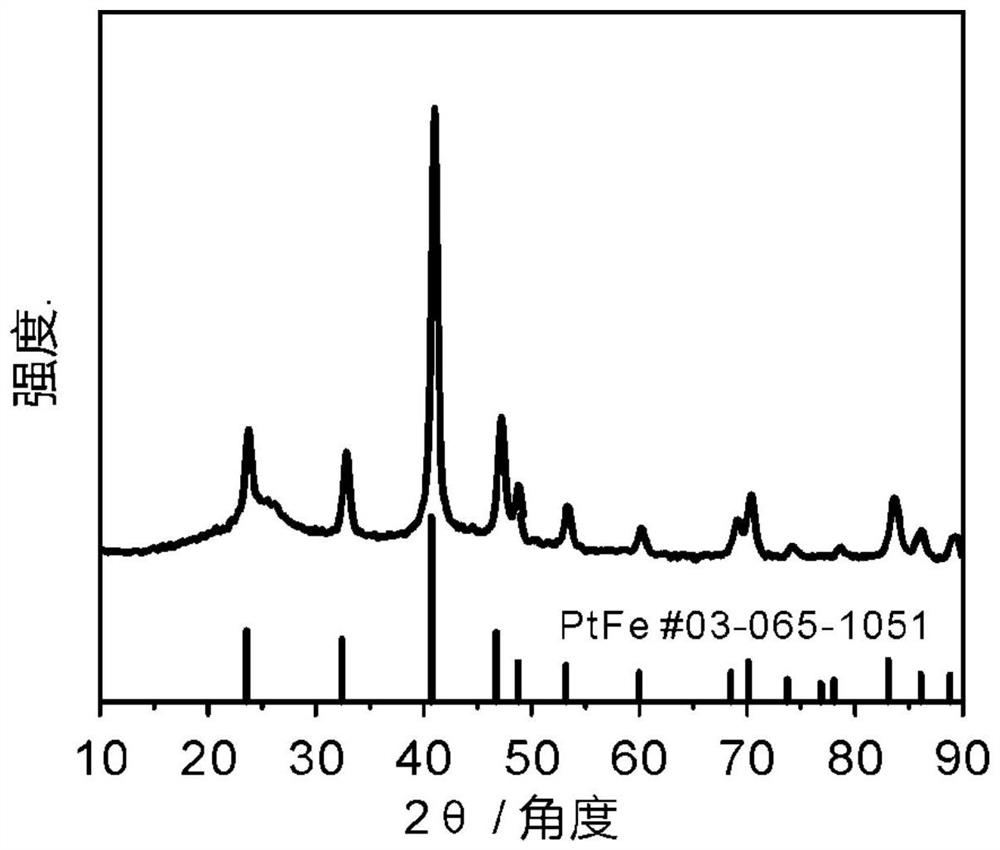

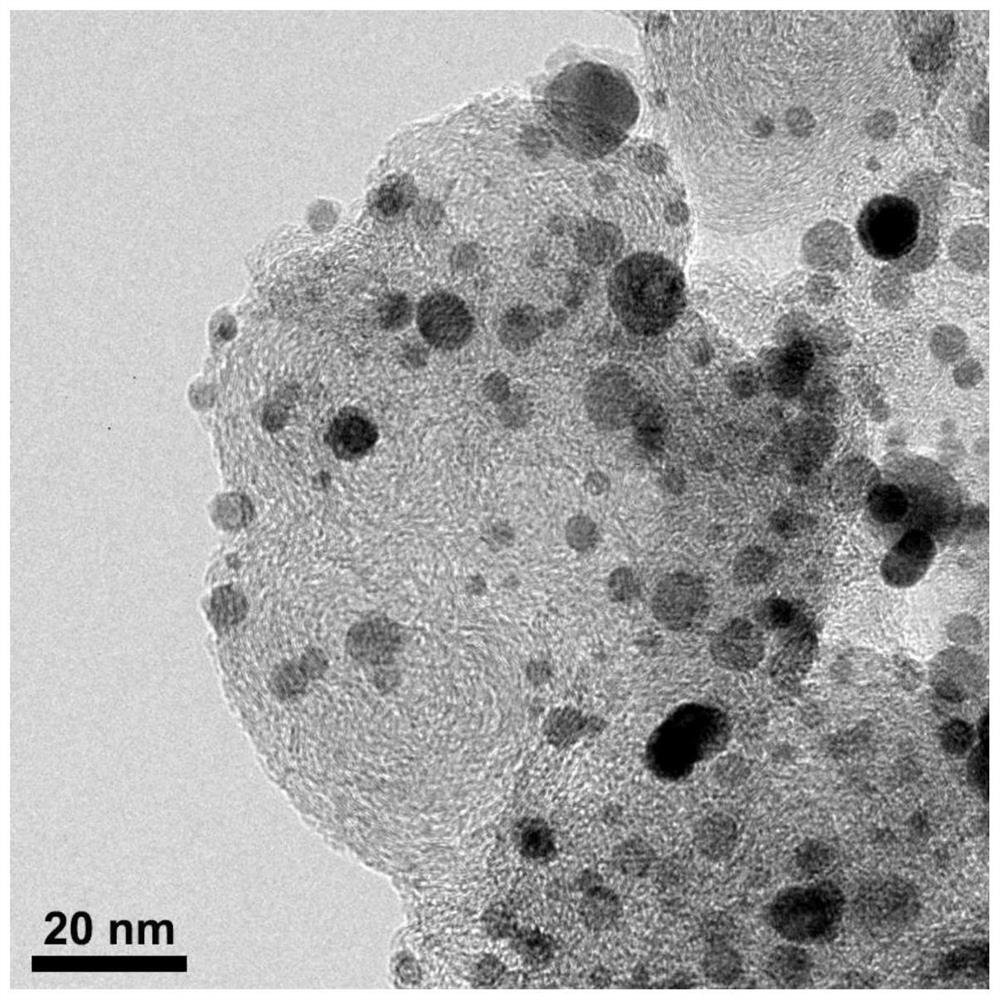

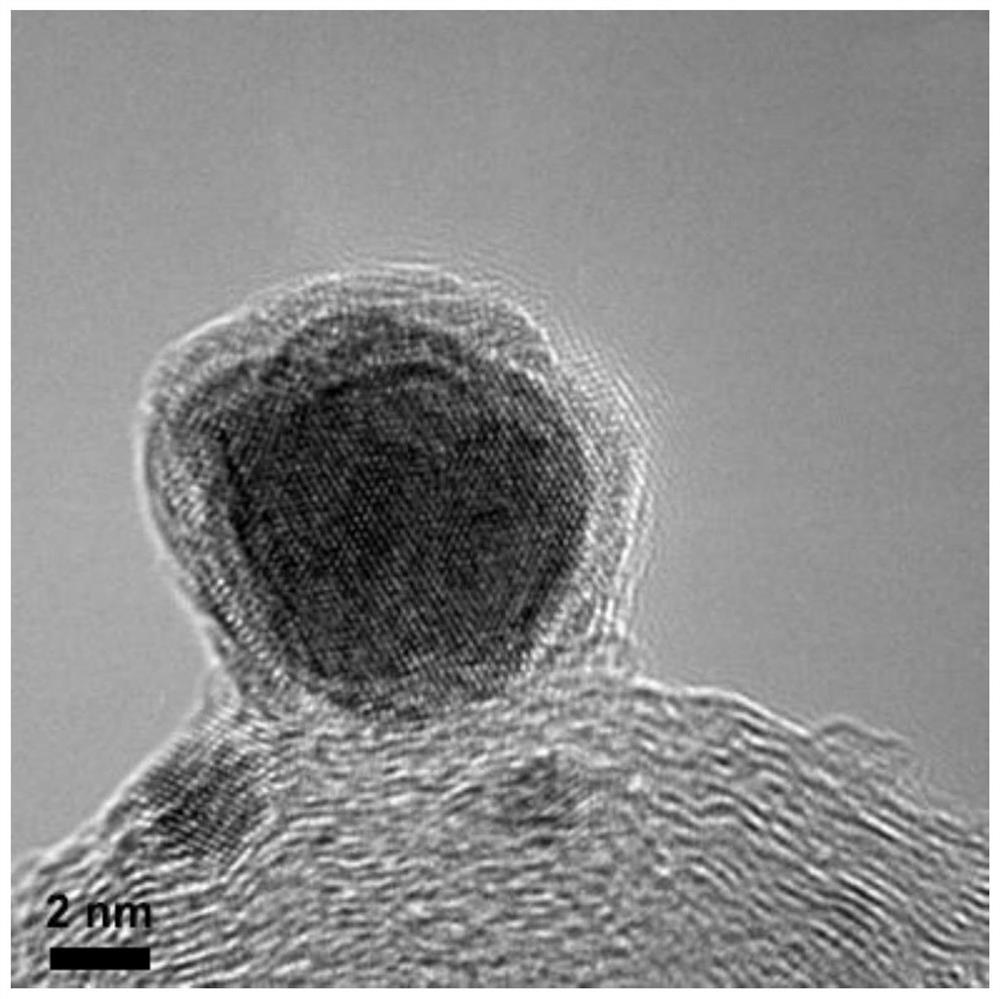

A platinum-iron intermetallic compound coated with nitrogen-doped carbon layer and its preparation and application

An intermetallic compound, nitrogen-doped carbon technology, applied in metal processing equipment, transportation and packaging, structural parts, etc., can solve problems such as poor stability, particle agglomeration, and low catalytic activity for oxygen reduction of intermetallic compounds, and achieve production costs Low, to ensure uniform dispersion, the effect of conducive to oxygen reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041](1) Add 0.05mol chloroplatinic acid, 0.1mol ferrous chloride, 0.1mol dicyandiamide and 35mg conductive carbon black to 20ml of water, stir well to form a mixture, stir and mix well, sonicate for 10min, then incubate at 50°C Heating and evaporating the remaining water to obtain a viscous substance; drying and grinding the obtained product at 100°C to obtain a solid powder containing a mixture of platinum precursor, iron precursor, amino compound and carbon black;

[0042] (2) Place the powder obtained in step (1) in a tube furnace, and perform high-temperature pyrolysis under an inert gas atmosphere; heat up to 900°C at a heating rate of 5°C / min, control the flow rate of the inert gas to 20ml / min, and Insulate at 900° C. for 5 hours, and take it out after the reaction cools down to room temperature, to obtain a small-sized nitrogen-doped carbon-coated PtFe intermetallic compound.

[0043] (3) Electrochemical performance test of nitrogen-doped carbon-coated PtFe intermetal...

Embodiment 2

[0046] (1) Add 0.05mol of chloroplatinic acid, 0.01mol of ferric nitrate, 0.15mol of dicyandiamide and 35mg of conductive carbon black into 50ml of water, stir well to form a mixture, stir and mix well, sonicate for 20min, then heat at 70°C The remaining water was evaporated to dryness to obtain a viscous substance; the obtained product was dried at 120° C. and ground to obtain a solid powder containing a mixture of platinum precursor, iron precursor, amino compound and carbon black.

[0047] (2) Place the powder obtained in step (1) in a tube furnace, and perform high-temperature pyrolysis under an inert gas atmosphere; heat up to 800°C at a heating rate of 10°C / min, control the flow rate of the inert gas to 40ml / min, and Insulate at 800°C for 4 hours, and take it out after the reaction cools down to room temperature, to obtain a small-sized nitrogen-doped carbon-coated PtFe intermetallic compound.

[0048] (3) Electrochemical performance test of nitrogen-doped carbon-coated ...

Embodiment 3

[0051] (1) Add 0.05mol of chloroplatinic acid, 0.1mol of ferrous chloride, 0.2mol of dicyandiamide and 35mg of conductive carbon black into 40ml of water, stir well to form a mixture, stir and mix well, ultrasonic for 30min, then at 60°C Heat and evaporate the remaining water to obtain a viscous substance; dry the obtained product at 150°C and grind it to obtain a solid powder containing a mixture of platinum precursor, iron precursor, amino compound and carbon black.

[0052] (2) Place the powder obtained in step (1) in a tube furnace, and perform high-temperature pyrolysis under an inert gas atmosphere; heat up to 800°C at a heating rate of 2°C / min, control the flow rate of the inert gas to 10ml / min, and Insulate at 800°C for 4 hours, and take it out after the reaction cools down to room temperature, to obtain a small-sized nitrogen-doped carbon-coated PtFe intermetallic compound.

[0053] (3) Electrochemical performance test of nitrogen-doped carbon-coated PtFe intermetalli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com