Method for treating activated carbon by chemical flocculation of radioactive waste liquid from nuclear facilities

A technology of radioactive waste liquid and chemical flocculation, applied in chemical instruments and methods, radioactive pollutants, inorganic chemistry, etc., can solve the problems of high difficulty in removal, large proportion of colloidal/granular corrosion products, etc., and meet the needs of engineering applications , The effect of waste minimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the above objectives, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

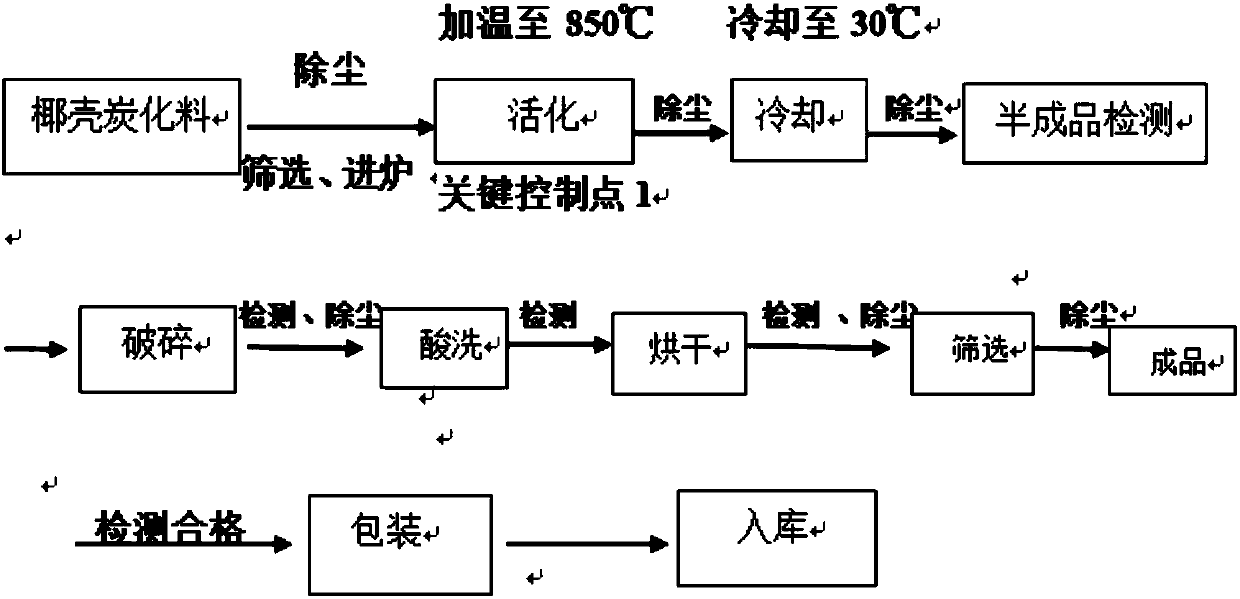

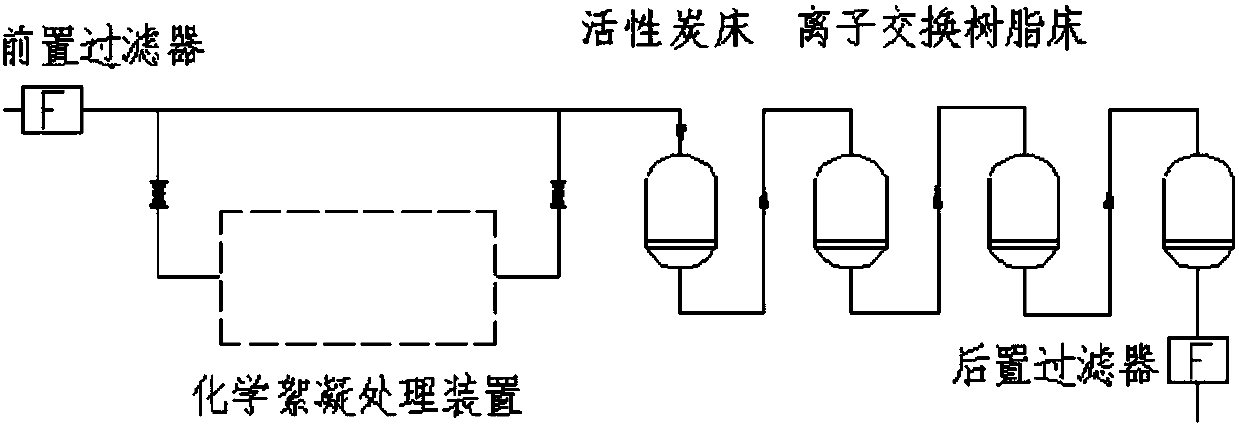

[0022] Such as figure 1 As shown, the method for chemical flocculation treatment of activated carbon from radioactive waste liquid of a nuclear facility provided by an embodiment of the present invention includes the following steps:

[0023] 1. Material selection:

[0024] Activated carbon substrates on the market mainly include coal, wood and coconut shell. In order to meet the special requirements of engineering applications on the mechanical strength and chemical stability of activated carbon, the present invention selects high fixed carbon content, thick wood layer, and inorganic salt content. And imported coconut shell with less ash to ensure that the ash content of the finished product is less than 4% and the strength...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com