Preparation method for NaV6O15 film and prepared NaV6O15 film

A thin film and substrate technology, applied in the field of NaV6O15 thin film, can solve problems such as the difficulty of preparing thin films of different specifications, and achieve the effects of energy saving, pollution-free reaction conditions, sufficient space, and good reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

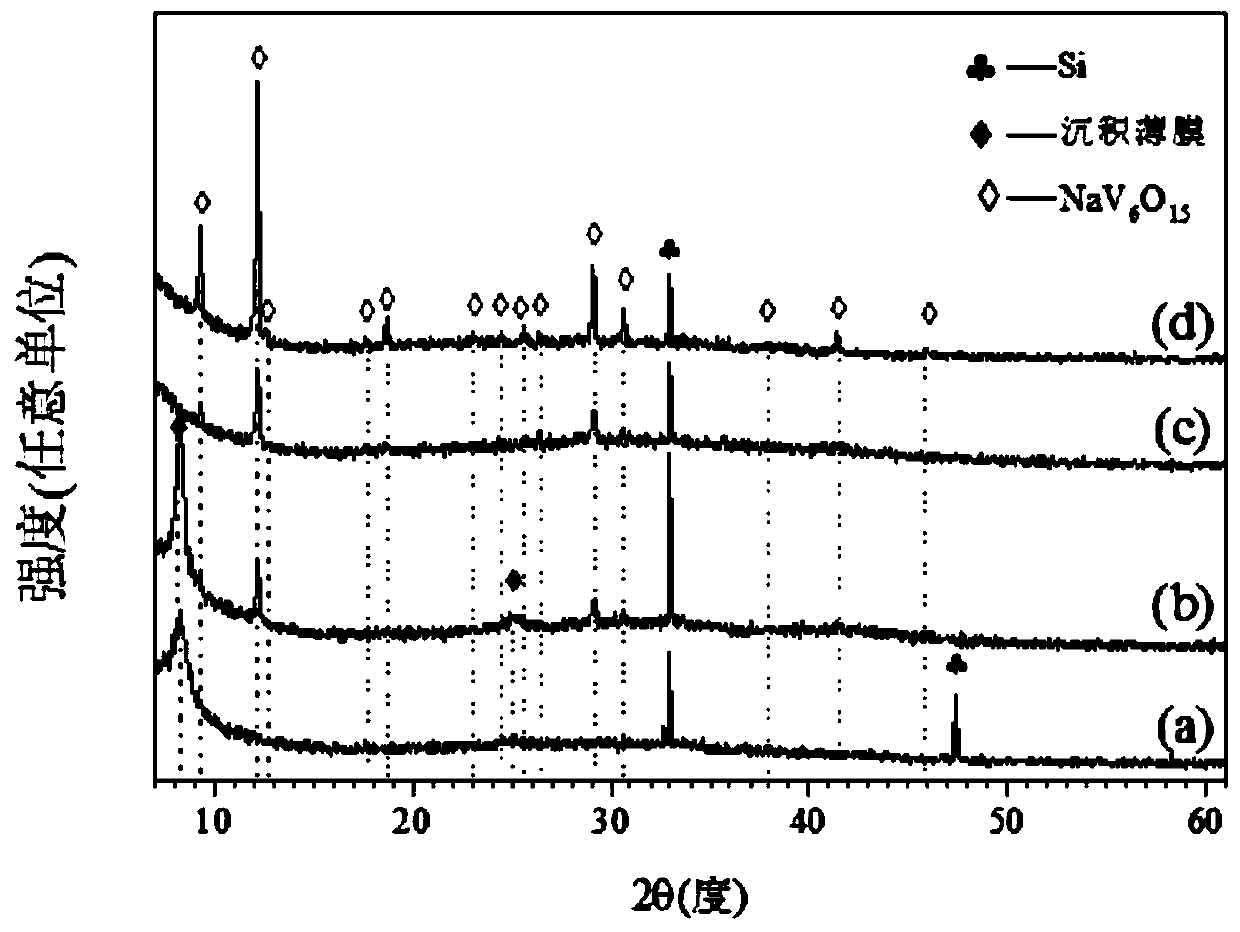

Embodiment 1

[0062] A NaV 6 o 15 The preparation method of thin film, comprises the following steps:

[0063] (1) Weigh 1.6323g VOSO according to the molar concentration ratio of 2:1 4 Prepare a mixed solution with 0.4535g oxalic acid to make it fully complexed;

[0064] (2) Add NaOH solution to adjust pH=3.19, set the volume to 50ml, place the cleaned Si substrate horizontally in the mixed solution prepared in step (1);

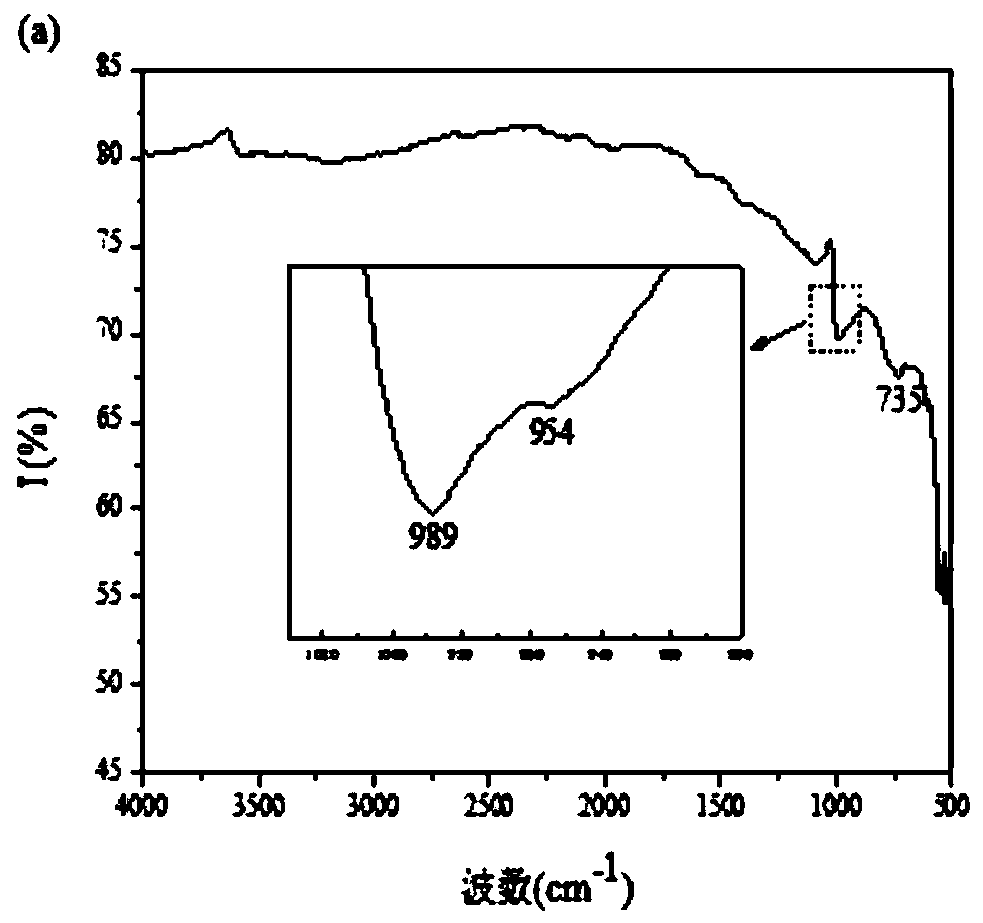

[0065] (3) React the mixed solution put into the substrate in step (2) at a constant temperature of 75° C. for 8 hours, take out the substrate, wash it and dry it to obtain a deposited film, which is named deposited film a;

[0066] (4) Take film a, divide it into two parts, take half of it and anneal at 300°C for 2 hours and cool down to room temperature with the furnace to obtain the product film, which is named product film b.

Embodiment 2

[0068] A NaV 6 o 15 The preparation method of thin film, comprises the following steps:

[0069] (1) Weigh 1.6370g VOSO at the ratio of molar concentration 2:1 4 Prepare a mixed solution with 0.4540g oxalic acid to make it fully complexed;

[0070] (2) Add NaOH solution to adjust the pH=3.13, set the volume to 50ml, and place the cleaned Si substrate horizontally in the mixed solution prepared in step (1);

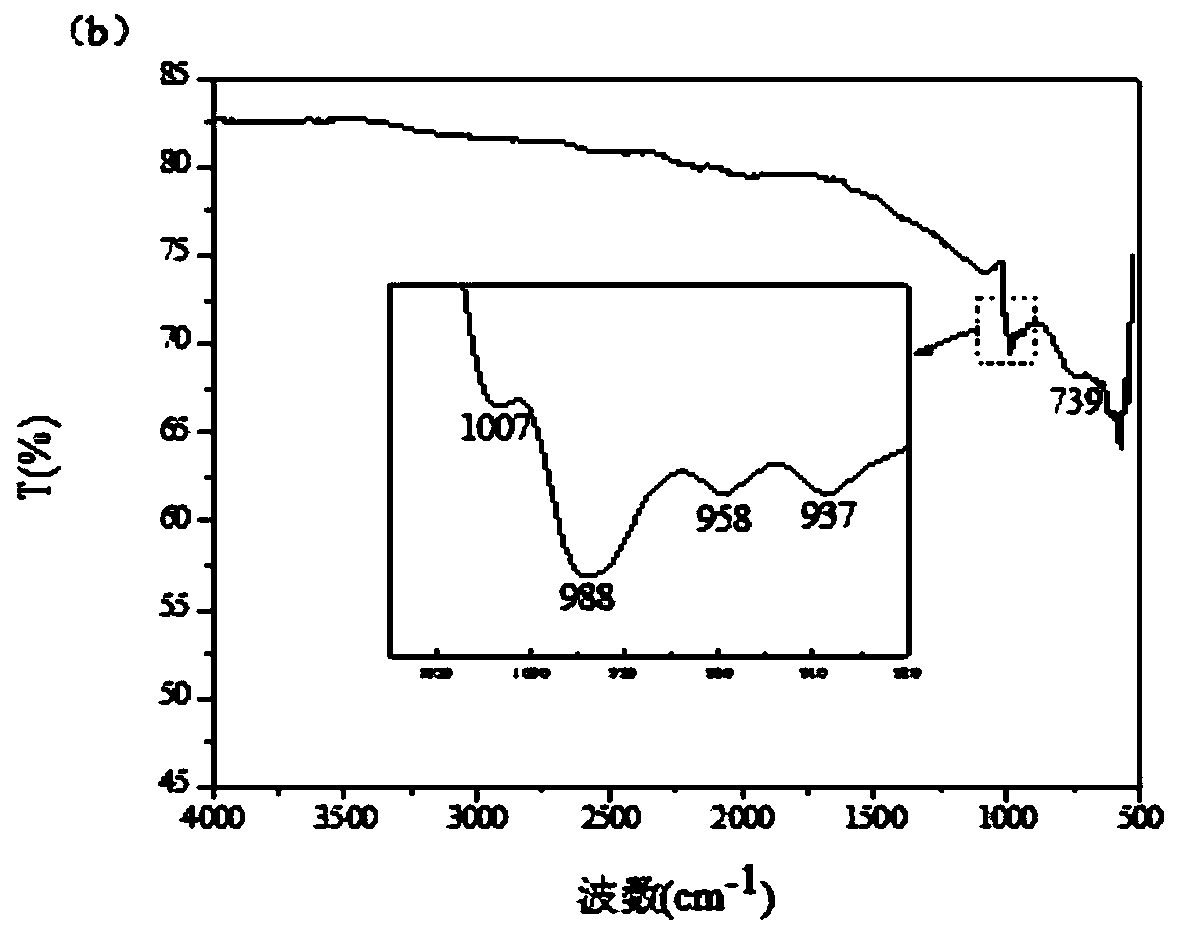

[0071] (3) React the mixed solution put into the substrate in step (2) at a constant temperature of 75° C. for 8 hours, take out the substrate, wash it and dry it to prepare a deposited film;

[0072] (4) Take the deposited film prepared in step (3), divide it into two parts, anneal at 400°C and 500°C for 2h respectively, and cool to room temperature with the furnace to obtain the product film, which is respectively named as product film c and product film d.

Embodiment 3

[0074] A NaV 6 o 15 The preparation method of thin film, comprises the following steps:

[0075] (1) Weigh 1.6362g VOSO according to the ratio of molar concentration 2:1 4 Prepare a mixed solution with 0.4573g oxalic acid to make it fully complexed;

[0076] (2) Add NaOH solution to adjust pH=2.85, set the volume to 50ml, place the cleaned ITO substrate horizontally in the mixed solution prepared in step (1);

[0077] (3) The mixed solution put into the substrate in step (2) was reacted at a constant temperature of 80° C. for 7 hours, and the substrate was taken out, washed and dried to obtain a deposited film, named as deposited film e.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com