A flexible copper-based chalcogenide semiconductor thin film solar cell window layer structure

A thin-film solar cell and semiconductor technology, applied in the field of solar cells, can solve the problems of reducing the cost of solar cells, poor bending resistance of the film layer, and large physical damage, and achieve the effects of avoiding battery short circuit, small reflection loss, and small physical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

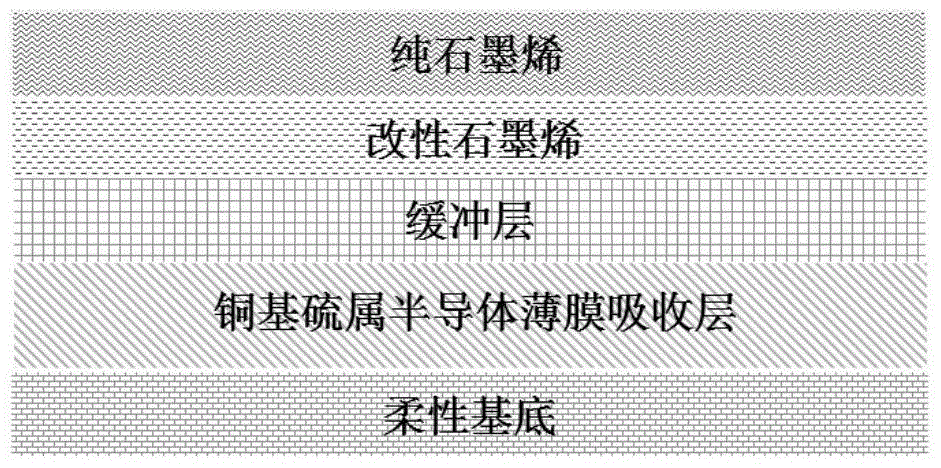

[0024] Design and fabricate the window layer structure of flexible copper-based chalcogenide semiconductor thin film solar cells (as shown in the schematic figure 1shown). The oxidation-reduction method is used to add 4g of flake graphite, 72mL of concentrated sulfuric acid and 36mL of concentrated nitric acid into a beaker in an ice-water bath and stir until it is dispersed. Then slowly add 44g of potassium chlorate. After reacting for 100 hours, add dilute hydrochloric acid solution to dilute and suction filter several times. The filtered product was diluted with deionized water and sonicated for 1 h, then added with sodium hydroxide for flocculation, filtered with suction, washed with absolute ethanol until neutral and then dried to obtain graphene oxide. After the prepared graphene oxide and ammonium chloride are mixed at a mass ratio of 1:2, they are first pyrolyzed at 150-300°C for 1 hour under negative pressure, so that N atoms are doped in the graphene skeleton, and th...

Embodiment 2

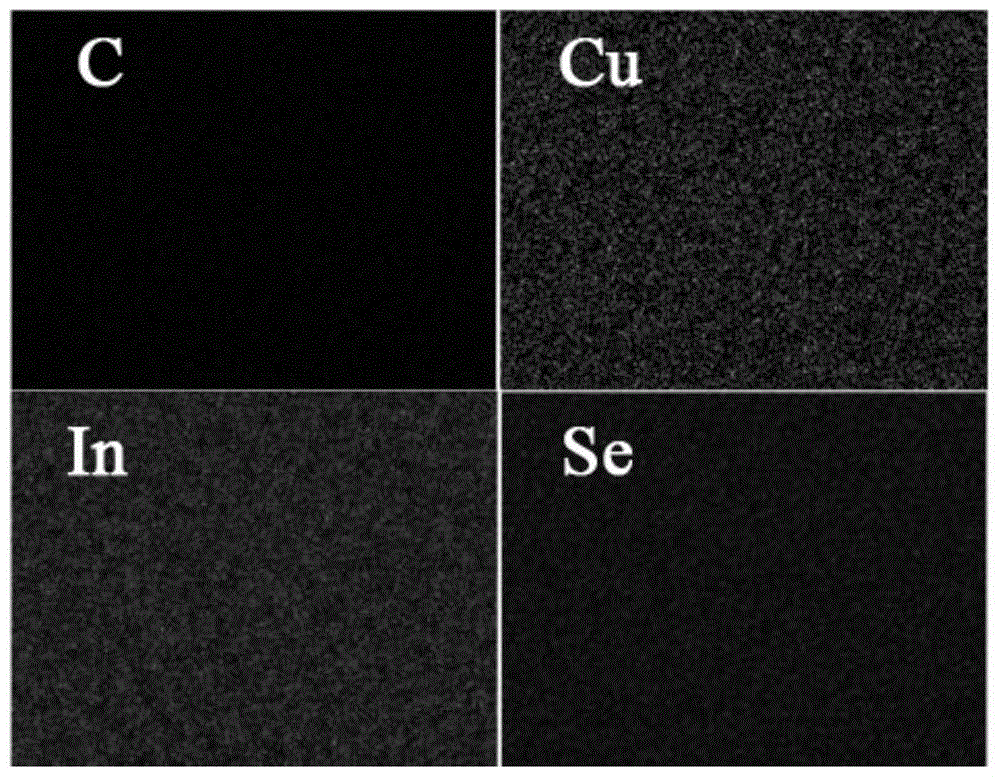

[0026] Design and fabricate the window layer structure of flexible copper-based chalcogenide semiconductor thin film solar cells. Using high-purity Cu foil (purity >99%) as the growth substrate, using methane as the carbon source in a tube furnace, and the carrier gas as the reducing gas H 2 , Graphene was prepared by CVD growth at 1000 °C, and polymethyl methacrylate (PMMA) was coated on the copper foil with graphene and then put into FeCl 3 In the solution to remove metal copper foil, obtain graphene (square resistance is 9Ωsq -1 , light transmittance of 97%) PMMA. Then the graphene on PMMA was covered with CdS / Cu(Ga,In)Se 2 / Mo, and remove PMMA with acetone, and then CdS / Cu(Ga,In)Se covered with graphene 2 CdS / Cu(Ga,In)Se covered with modified graphene 2 / Mo (i.e. modified graphene / CdS / Cu(Ga,In)Se 2 / Mo), the square resistance of modified graphene is 1500kΩsq -1 , The light transmittance is 86%. Then vapor-deposit Ni / Al / Ni top electrode on the modified graphene, and ...

Embodiment 3

[0028] Design and fabricate the window layer structure of flexible copper-based chalcogenide semiconductor thin film solar cells. CdS / CuBiSe 2 / Mo / SS (stainless steel) is the growth substrate, acetylene is used as the carbon source in the tube furnace, and the carrier gas is the reducing gas H 2 , Graphene was prepared by CVD growth at 400°C, and then placed in an ammonia atmosphere at 400°C for 4 hours and then hydrogenated in a 300Hz radio frequency plasma apparatus at 1 mbar for 2 hours to obtain a surface covered with modified graphene CdS / CuBiSe 2 / Mo / SS (stainless steel) (i.e. modified graphene / CdS / CuBiSe 2 / Mo / SS (stainless steel)), the square resistance of modified graphene is 1100kΩsq -1 , The light transmittance is 83%. Then prepare the graphene dispersion in the same way as in Example 1 and drop-coat it on the modified graphene, and dry it at 80° C. for 30 min to obtain a flexible graphene window layer copper-bismuth-selenium thin-film solar cell, and obtain a tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com