Anti-icing wind power generator blade and fabrication process thereof

A technology for wind turbines and manufacturing processes, applied in wind turbines, wind energy power generation, engines, etc., can solve the problems of preventing icing, damage to machines and personnel, and increasing the weight of blades that are not fundamentally solved, so as to improve UV resistance. and hydrophobicity, saving manpower and material resources, and improving the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with specific embodiments.

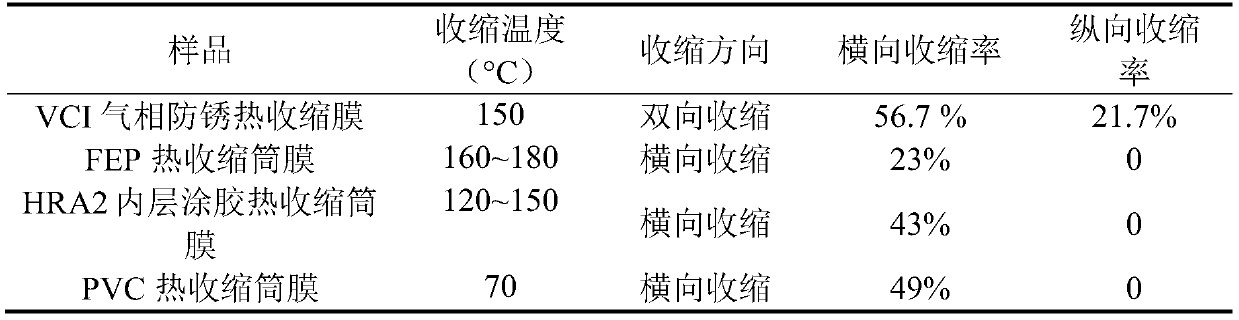

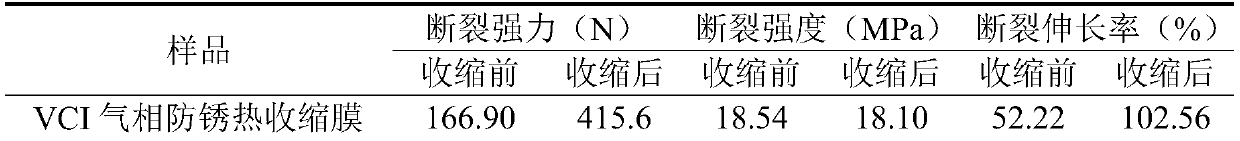

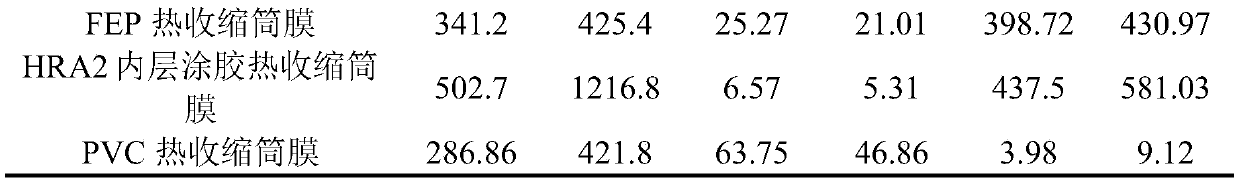

[0032] An anti-icing wind turbine blade, the surface of the PVC heat shrinkable film base material is treated with CF 4 After etching, it becomes a rough surface with multiple grooves and pits, and a PTFE coating is deposited on the rough surface. The grooves, pits and PTFE coating form a tight cross-linked network micro-nano surface structure, CF via ionic body 4 Etching the surface of the PVC heat-shrinkable film substrate provides a premise guarantee for improving the bonding fastness between the coating and the PVC heat-shrinkable film. In addition to roughening the surface of the film, CF4 plasma pretreatment introduces fluorine-containing groups, which provides the possibility for the deposition of fluorine-containing groups in the next step, and then improves the bonding fastness between the two, and strengthens the PTFE coating The combination with the substrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com