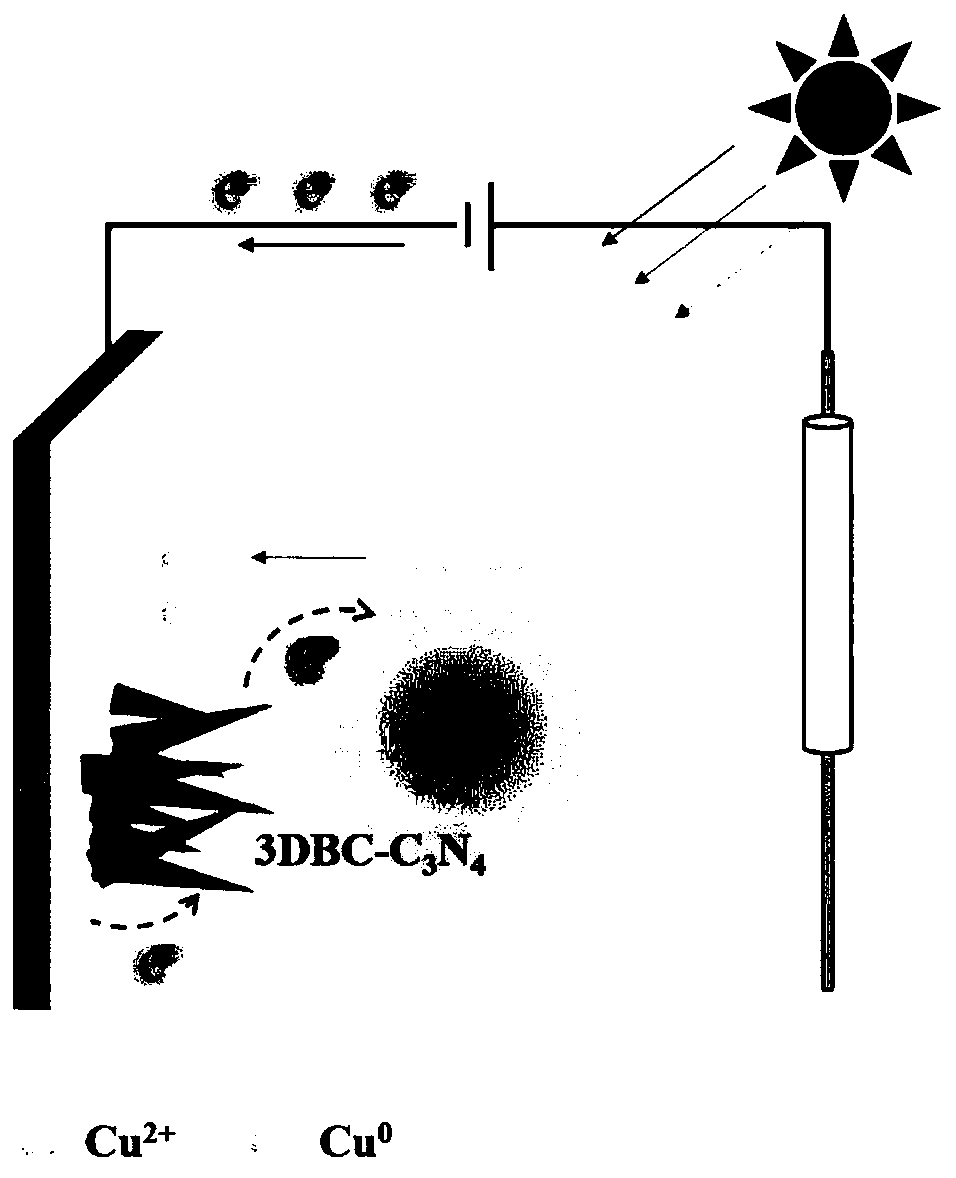

Trace copper ion photoelectrochemistry detection method based on three-dimensional needle point type carbon nitride

A carbon nitride and photoelectrochemical technology, which is applied in the field of photoelectrochemical sensing and detection of trace copper ions based on three-dimensional needle-shaped carbon nitride, can solve the problems of complex processing, poor anti-interference, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

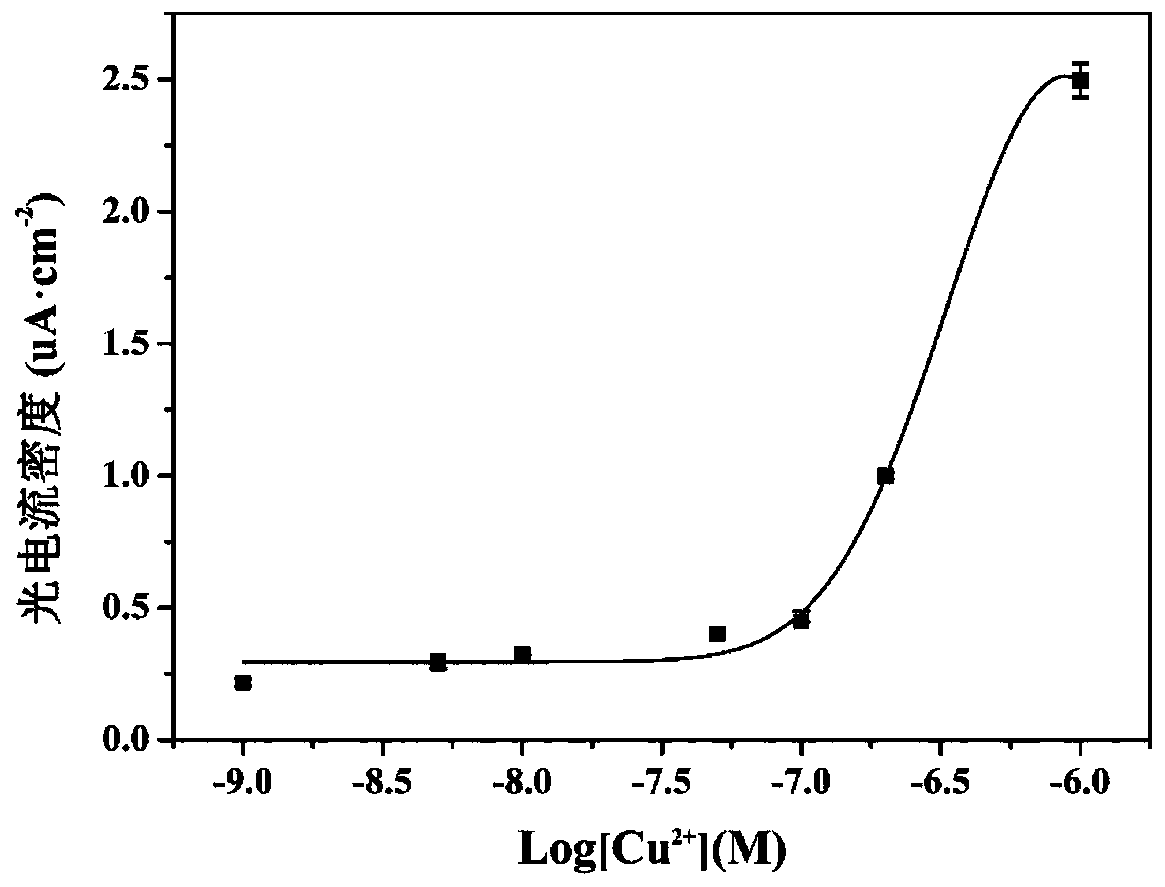

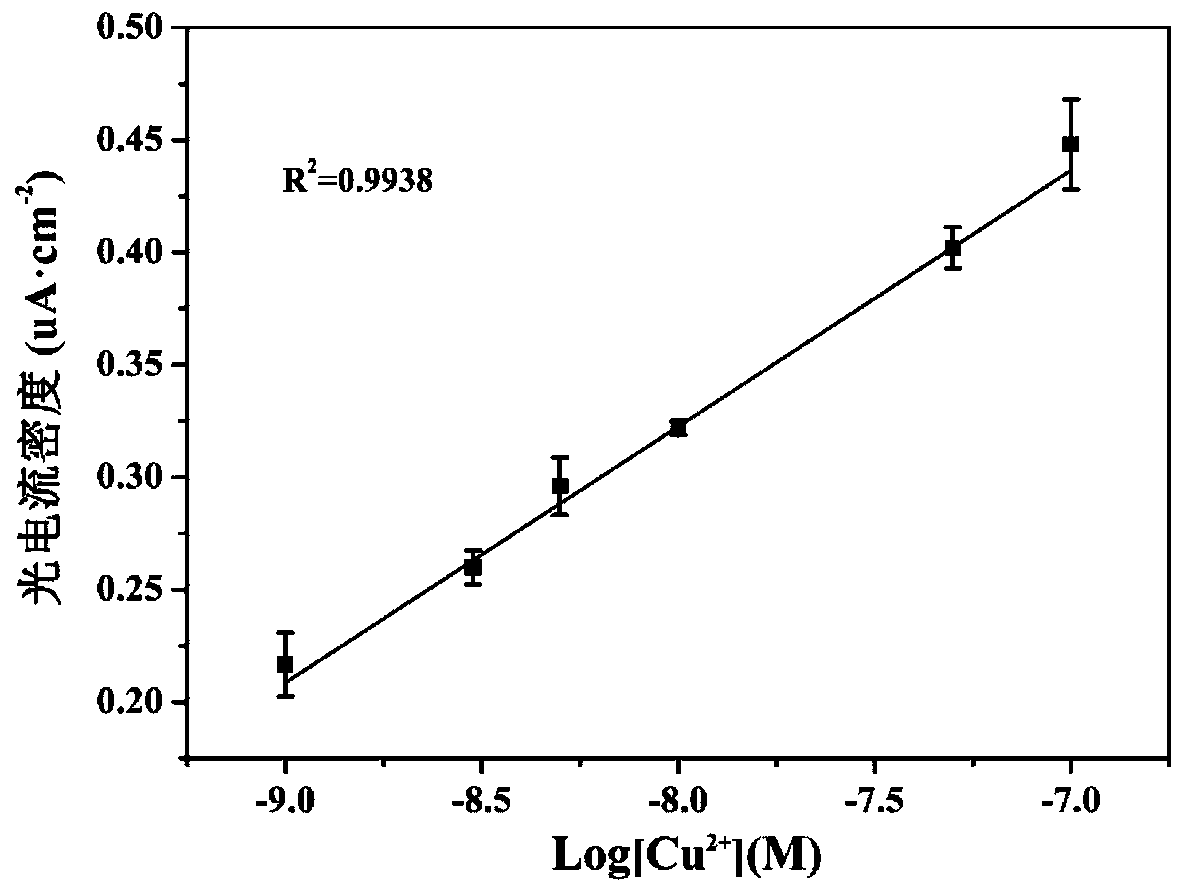

Examples

Embodiment 1

[0022] Determination of copper content in configuration water samples:

[0023] (1) Preparation of three-dimensional needle-shaped carbon nitride: a two-step method was used to prepare three-dimensional needle-shaped carbon nitride. The steps are as follows: Take 10g of melamine in a 50mL crucible with a lid, put it into a muffle furnace, raise the temperature to 550°C at a rate of 10°C per minute, and then keep it warm for 4 hours. After the sample is cooled to room temperature, the obtained yellow powder is the original carbon nitride. Next, take 1 g of the above yellow powder sample and mix it with 6 g of LiCl and KCl two eutectic salts (mass ratio is 9:11), grind it thoroughly, and place it in another crucible. Heating was performed using a vacuum tube furnace under an argon atmosphere. The heating rate was 5°C per minute, and the temperature was maintained for 4 hours after reaching 550°C. When the sample is cooled to a specific temperature, it is taken out immediately...

Embodiment 2

[0031] Determination of copper ion content in tap water samples:

[0032] (1) Preparation of three-dimensional needle-shaped carbon nitride: a two-step method was used to prepare three-dimensional needle-shaped carbon nitride. The steps are as follows: Take 10g of melamine in a 50mL crucible with a lid, put it into a muffle furnace, raise the temperature to 550°C at a rate of 10°C per minute, and then keep it warm for 4 hours. After the sample is cooled to room temperature, the obtained yellow powder is the original carbon nitride. Next, take 1 g of the above yellow powder sample and mix it with 6 g of LiCl and KCl two eutectic salts (mass ratio is 9:11), grind it thoroughly, and place it in another crucible. Heating was performed using a vacuum tube furnace under an argon atmosphere. The heating rate was 5°C per minute, and the temperature was maintained for 4 hours after reaching 550°C. When the sample is cooled to a specific temperature, it is taken out immediately and q...

Embodiment 3

[0040] Determination of copper ion content in river samples:

[0041] (1) Preparation of three-dimensional needle-shaped carbon nitride: a two-step method was used to prepare three-dimensional needle-shaped carbon nitride. The steps are as follows: Take 10g of melamine in a 50mL crucible with a lid, put it into a muffle furnace, raise the temperature to 550°C at a rate of 10°C per minute, and then keep it warm for 4 hours. After the sample is cooled to room temperature, the obtained yellow powder is the original carbon nitride. Next, take 1 g of the above yellow powder sample and mix it with 6 g of LiCl and KCl two eutectic salts (mass ratio is 9:11), grind it thoroughly, and place it in another crucible. Heating was performed using a vacuum tube furnace under an argon atmosphere. The heating rate was 5°C per minute, and the temperature was maintained for 4 hours after reaching 550°C. When the sample is cooled to a specific temperature, it is taken out immediately and quenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com