Billet counting device and method based on machine vision technology

A machine vision and billet technology, which is applied in the field of billet counting devices, can solve the problems of measurement error, unfixed quantity, and difficulty in meeting the cost accounting requirements of steelmaking plants, so as to avoid identification errors and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

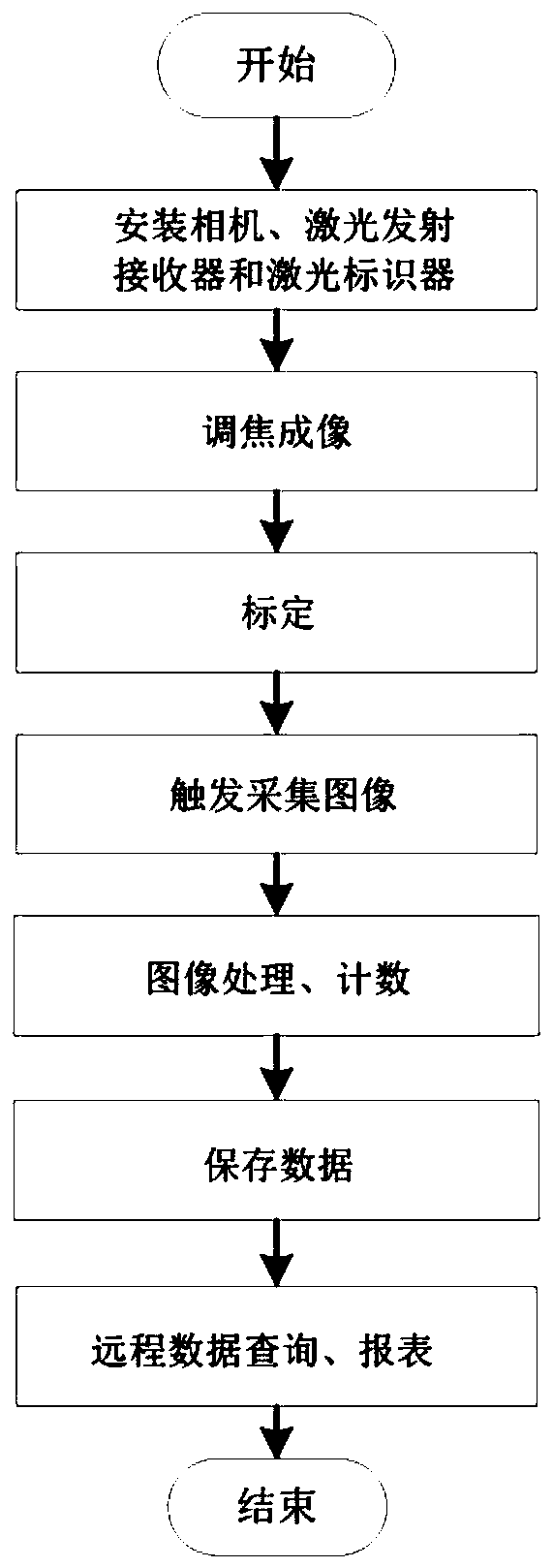

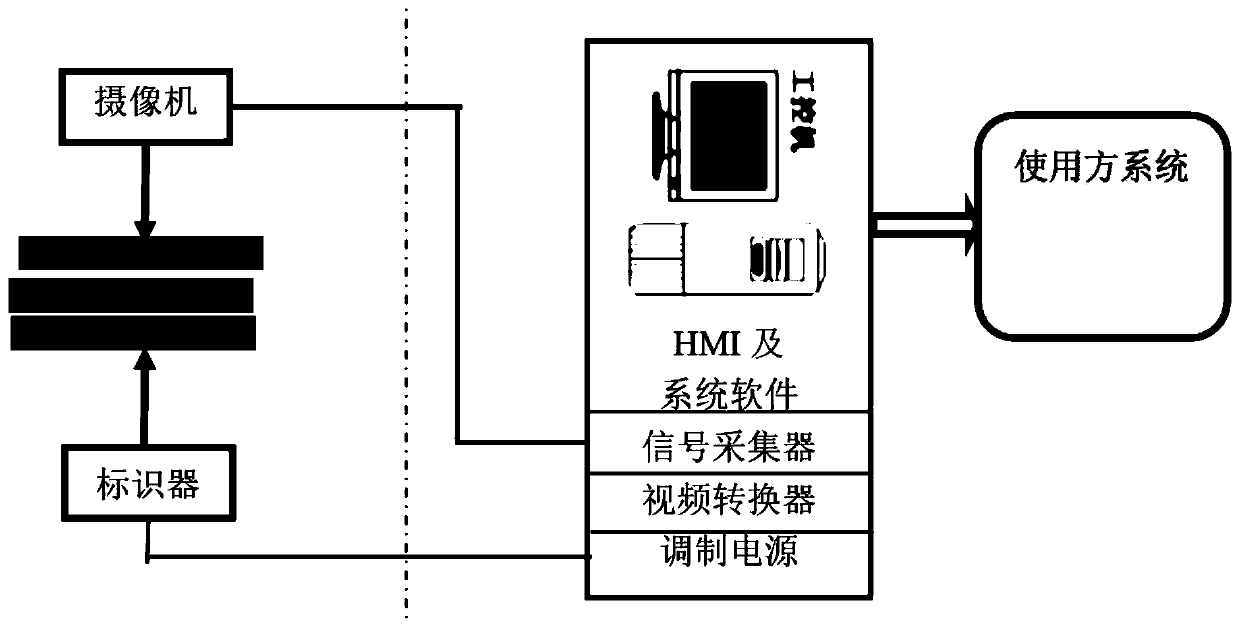

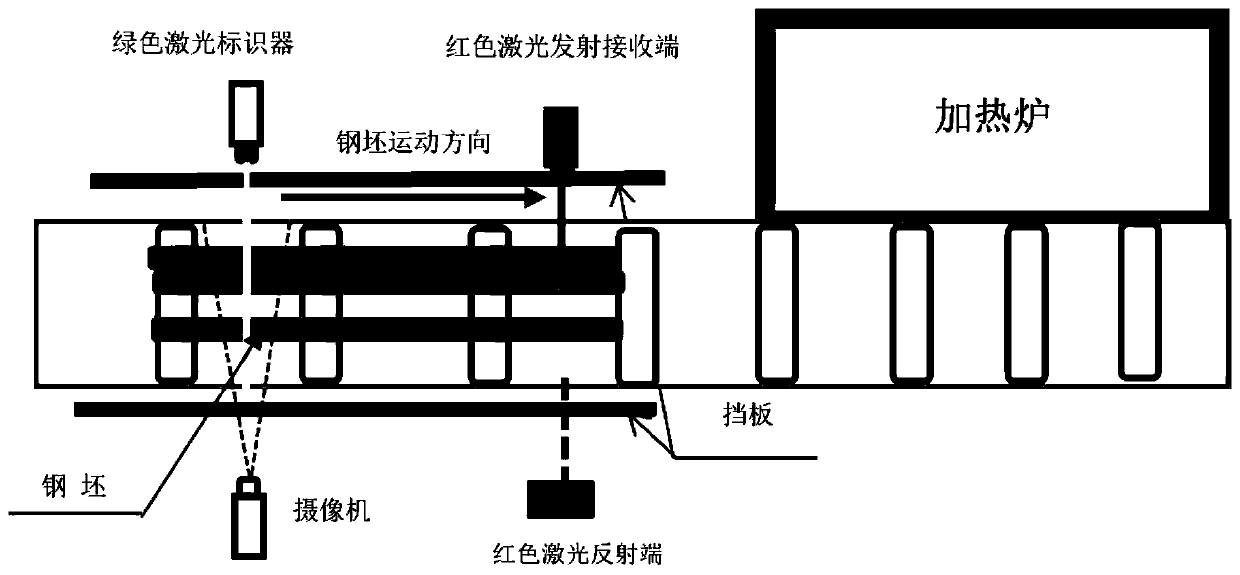

[0037] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0038] Machine vision inspection technology uses image processing to complete industrial measurement and inspection. It has the advantages of simple structure, non-contact, good flexibility, high precision, fast speed, high level of automation and intelligence, and can well meet the inspection requirements and ensure product quality. Through the application of billet counting devices and methods based on machine vision technology, together with powerful data acquisition and processing software, it can meet the requirements of accurate counting of billet counts and steelmaking cost accounting in steelmaking plants, and at the same time reduce the labor intensity of staff And the errors caused by manual calculations, so that the billets can be counted accurately. Through the automatic o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com