Non-porous breathable film as well as preparation method and application thereof

A film and surface structure technology, applied in applications, chemical instruments and methods, building components, etc., can solve the problems of film separation, high production cost, poor film flexibility, etc., to reduce elastic modulus, improve adhesion performance, The effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

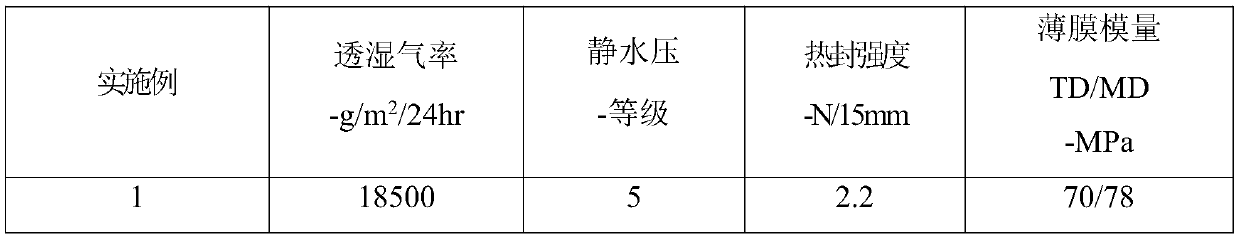

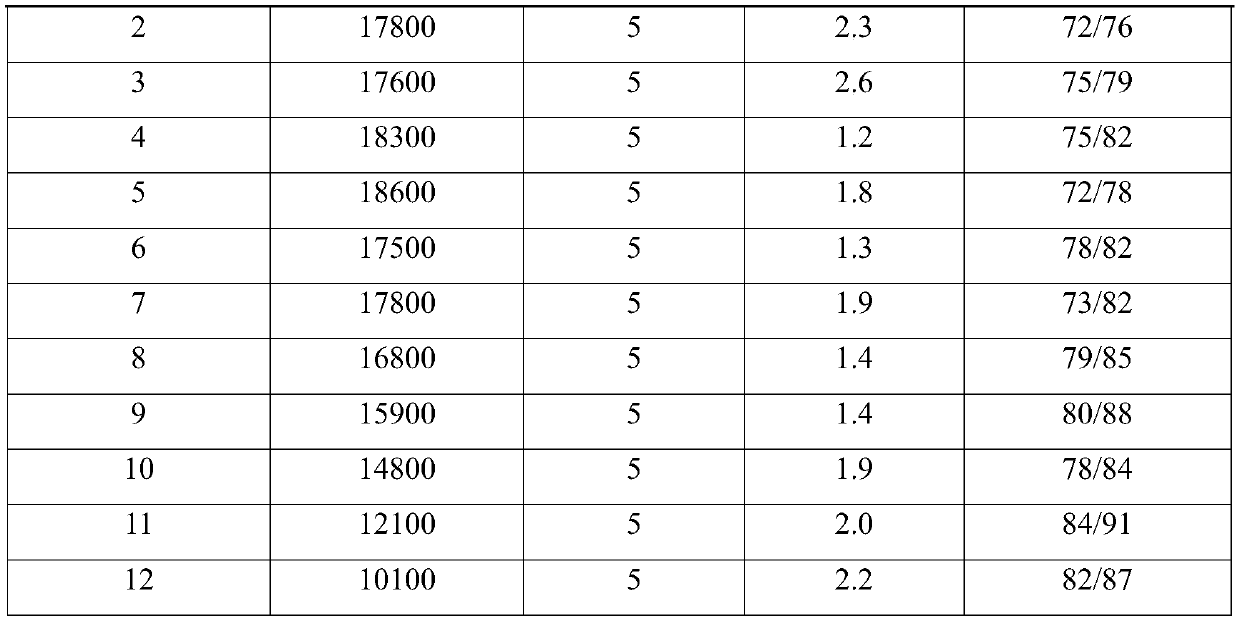

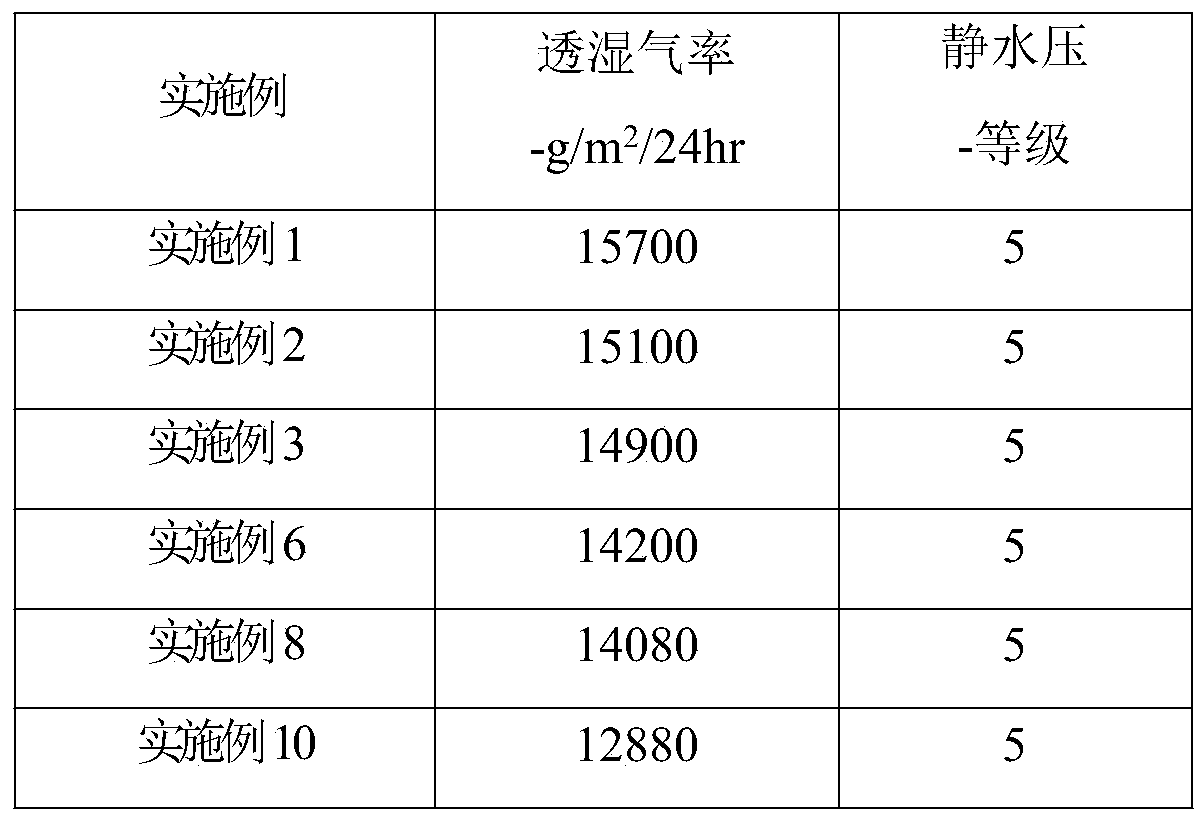

Examples

Embodiment 1

[0041] A non-porous and breathable film comprising an upper layer, a middle layer and a lower layer, the middle layer is a core layer structure, the upper layer and the lower layer are different surface layer structures, the thickness of the film is 20 μm, and the width is 500-2600 mm; wherein, the thickness of the middle layer is 12.0 μm , the thickness of the upper layer is 3.0 μm, and the thickness of the lower layer is 5.0 μm.

[0042] The carrier resin used in the core structure is copolyether ester, and the melting point of the resin is 220°C. The copolyether ester is composed of hard segment ester resin and soft segment ether resin. The weight ratio is 80:20; wherein, the hard-segment ester resin is benzoate, and the soft-segment ether resin is fatty ether. Functional additives including an anti-UV agent and an anti-adhesive agent are also added to the core layer structure, wherein the weight of the anti-UV agent accounts for 0.5% of the film weight, and the weight of t...

Embodiment 2

[0048] A non-porous and breathable film, comprising an upper layer, a middle layer and a lower layer, the middle layer is a core layer structure, the upper layer and the lower layer have the same surface layer structure, the thickness of the film is 30 μm, and the width is 500-2800 mm; wherein, the thickness of the middle layer is 22.0 μm , the thickness of the upper and lower layers is 4.0 μm.

[0049] The carrier resin used in the core structure is copolyether ester, the melting point of which is 220°C. The copolyether ester is composed of hard segment ester resin and soft segment ether resin. The weight of hard segment ester resin and soft segment ether resin is The ratio is 80:20; wherein, the hard segment ester resin is benzoate, and the soft segment ether resin is fatty ether. Functional additives including an anti-UV agent and an anti-adhesive agent are also added to the core layer structure, wherein the weight of the anti-UV agent accounts for 0.4% of the weight of the...

Embodiment 3

[0055] A non-porous and breathable film comprising an upper layer, a middle layer and a lower layer, the middle layer is a core layer structure, the upper layer and the lower layer are different surface layer structures, the thickness of the film is 30 μm, and the width is 500-2800 mm; wherein, the thickness of the middle layer is 20.0 μm , the thickness of the upper layer is 4.0 μm, and the thickness of the lower layer is 6.0 μm.

[0056] A non-porous and breathable film, the film has a three-layer structure in the shape of "A / B / C", the thickness of the film is 30 μm, and the width is 500-2800 mm; among them, the "B" layer is the core layer with a thickness of 20.0 μm The "A" layer is the surface structure with a thickness of 4.0 μm, and the "C" layer is the surface structure with a thickness of 6.0 μm.

[0057] The carrier resin used in the core layer structure is copolyether ester, the melting point of which is 230°C. The copolyether ester is composed of hard segment ester ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com