Process for preparing benzo selenophen compound by catalytic method

A technology of benzoselenophene and compounds, which is applied in the field of preparation of heterocyclic compounds, can solve the problems of low reaction yield, high cost, and expensive Se-containing compounds, and achieve simple operation, short reaction cycle, and good scalability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: the impact of different catalyst additions on synthetic effect

[0035] During the preparation process, we tried a variety of catalysts, and finally determined that silver oxide had the best catalytic effect. Using this catalyst not only improved the reactivity of raw materials, but also promoted the forward progress of the reaction; then we The addition ratio of the catalyst was also tested, see Table 1 for details.

[0036] Table 1 The influence of different catalyst additions on the synthesis effect

[0037] serial number Ag 2 O, mol%

[0038] In the presence of 2-(phenylethynyl)benzoselenide (2mmol) as the raw material, silver oxide as the catalyst, and acetic acid (20ml) as the solvent, stir at room temperature (25°C) for 1.5h, then add 50mL of 1M Sodium hydroxide solution, extracted with 2x30mL dichloromethane, combined the organic phases, dried overnight with anhydrous sodium sulfate or anhydrous magnesium sulfate, spin-dried, and pas...

Embodiment 2

[0039] Embodiment 2: the influence of different acidic solvents on synthetic effect

[0040]In the previous research, we preliminarily characterized the solvent as an acidic solvent, and the acidic solvent can well guide the forward reaction (that is, 2-ethynyl benzoselenide derivative → benzoselenophene compound); In the experiment, we used the same raw materials and reaction time to conduct experiments in solvent systems composed of different acids, and comprehensively considered the indicators such as the time of reaction end point in different systems, the stability of the compound, and the purity of the compound, combined with Table 2 , the results show that: the use of acetic acid and trifluoroacetic acid to guide the effect of the reaction is the best, at this time, the reaction is kept under acidic conditions, silver oxide and raw materials can be fully contacted.

[0041] The influence of table 2 different acidic solvents on synthetic effect

[0042] serial...

Embodiment 3

[0048] Embodiment 3: 2-(phenylethynyl) benzoselenophene (A 1 ) preparation

[0049] Add 2-(phenylethynyl)benzoselenide (542.4mg, 2mmol), silver oxide (23.1mg, 0.1mmol), acetic acid (20mL) in turn to a 25mL round bottom flask, and stir the reaction at room temperature (25°C) for 1.5 hours , then add 50mL of 1M sodium hydroxide solution to the reaction system, extract with 2x30mL dichloromethane, combine the organic phases, dry overnight with anhydrous sodium sulfate or anhydrous magnesium sulfate, spin dry, use petroleum ether: ethyl acetate = 50 : 1 through the column to obtain 473.2 mg of the target compound as a white solid with a yield of 92%.

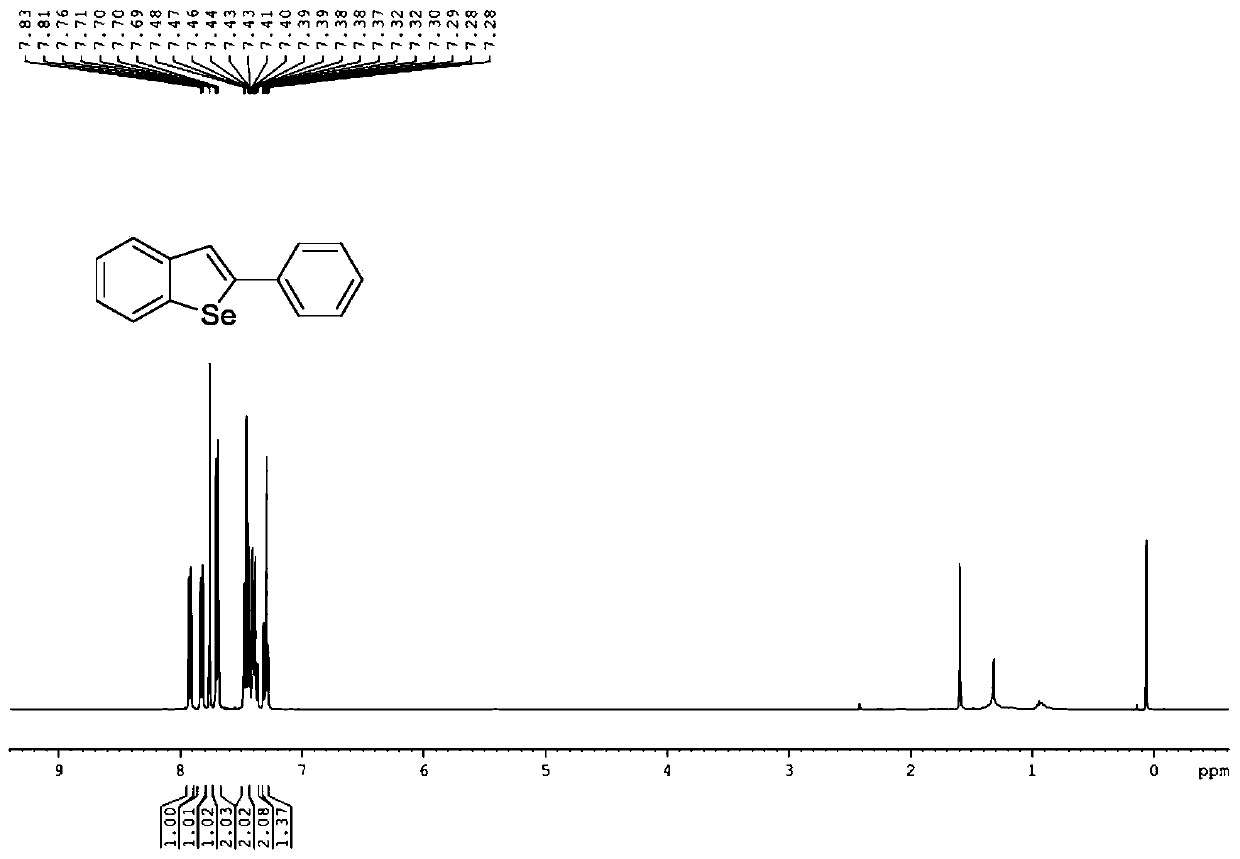

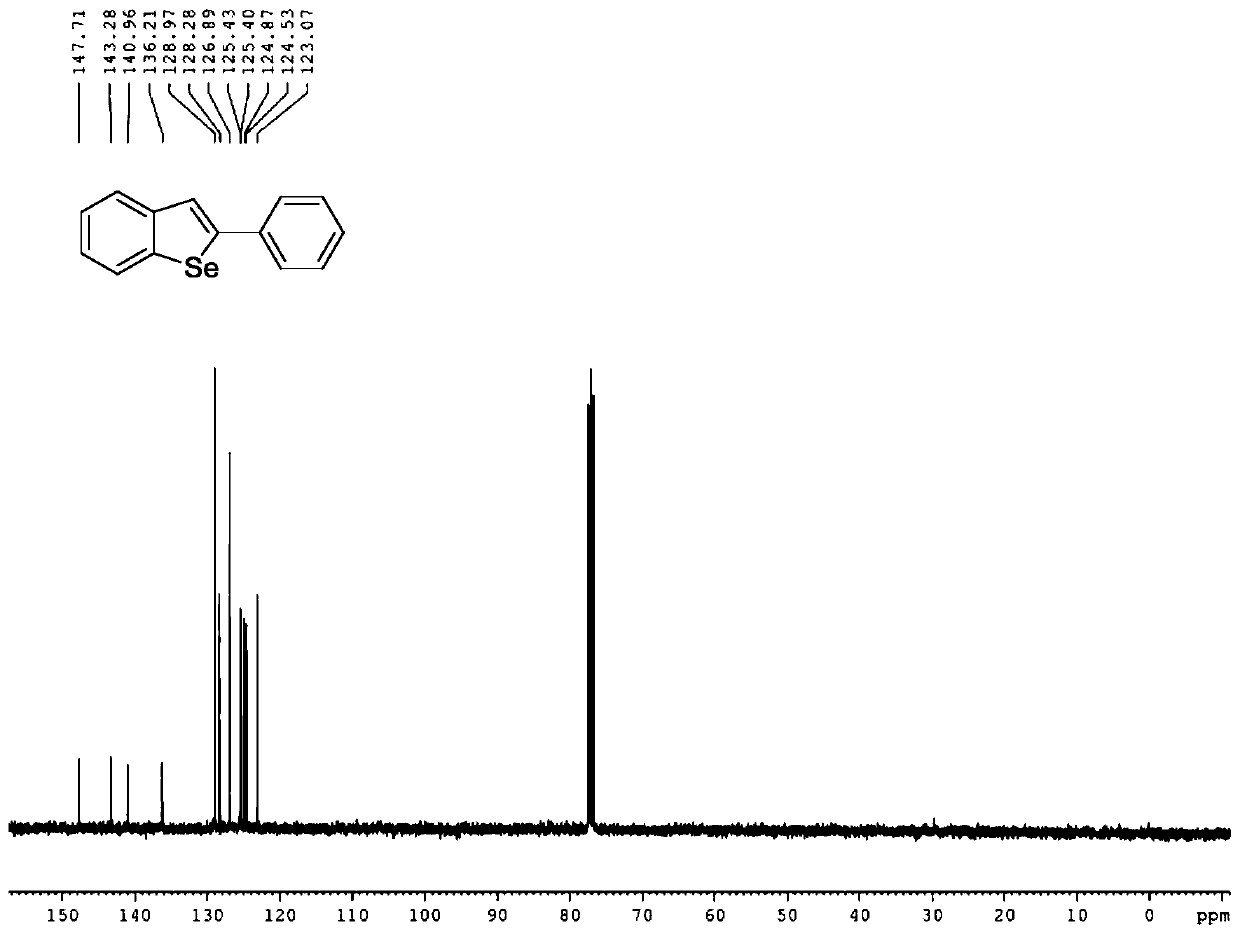

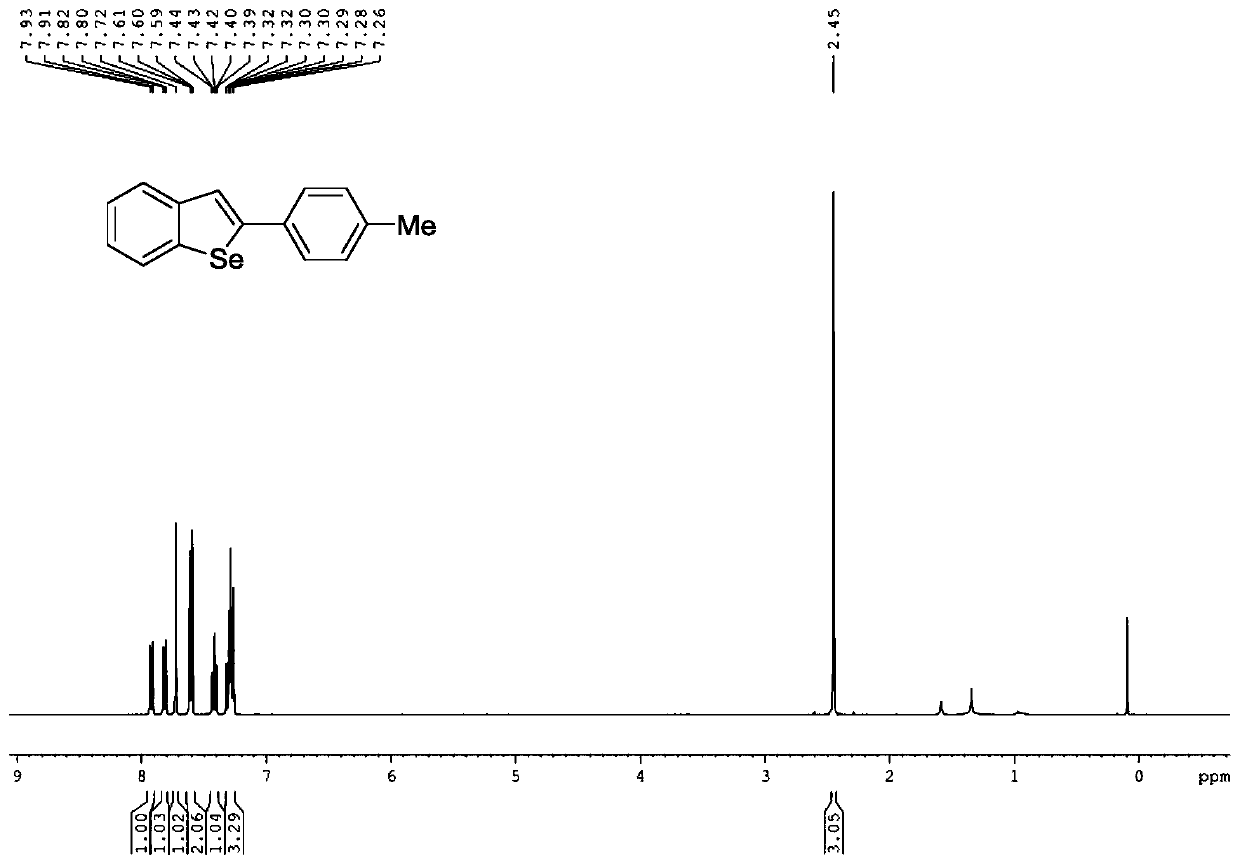

[0050] The product structure is: That 1 H spectrum, 13 C spectrum see Figure 1A , 1B . 2-phenylbenzo[b]selenophene

[0051] 1 H NMR (400MHz, CDCl 3 )δ7.92(dd, J=7.9,1.2Hz,1H),7.82(dd,J=7.9,1.2Hz,1H),7.76(s,1H),7.72–7.66(m,2H),7.48–7.44 (m,2H),7.43–7.38(m,2H),7.33–7.26(m,1H);

[0052] 13 C NMR (101MHz, CDCl 3 )δ147.72...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com