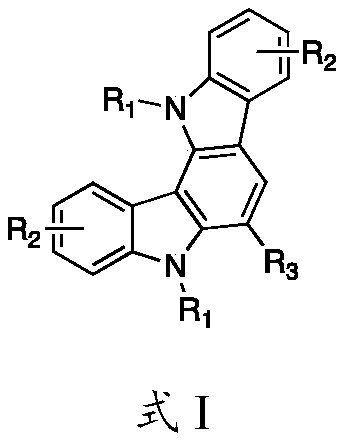

Preparation method of indolocarbazole compound

A technology for indolocarbazoles and compounds, which is applied in the field of preparation of indolocarbazoles, can solve the problems of low diversity of reaction substrates and mild conditions, and achieves wide application range and mild reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

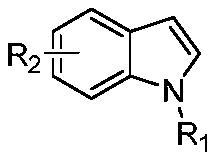

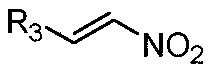

Method used

Image

Examples

Embodiment 1

[0049] Example 1 6-(4-ethoxyphenyl)-5,12-dimethyl-5,12-dihydroindolo[3,2-a]carbazole

[0050]

[0051] Add 1-ethoxy-4-(2-nitrovinyl)benzene (0.5mmol, 96.5mg), 1-methylindole (1.0mmol, 131mg), trifluoroacetic acid (1.0mmol, 74μL) into 8mL In 1,2-dichloroethane, after the addition, react at room temperature for 24 hours, and spot plate observation. After the reaction was completed, NaOH (1M) was added to the reaction solution to neutralize it to neutrality, and then the column was extracted to obtain a white solid. The extraction is extracted 3 times with ethyl acetate, the combined ethyl acetate layer is washed once with saturated brine, dried over anhydrous sodium sulfate and spin-dried to dry the solvent under reduced pressure, and extracted with silica gel column chromatography, the chromatographic conditions of ethyl acetate : petroleum ether = 1:100.

[0052] White solid, m.p.207.4-208.1℃, 1 H NMR (500MHz, CDCl 3 )δ8.58(d,J=8.0Hz,1H),7.59-7.56(m,2H),7.48-7.46(m,3H),...

Embodiment 2

[0053] Example 2 6-(2-bromophenyl)-5,12-dimethyl-5,12-dihydroindolo[3,2-a]carbazole

[0054]

[0055] The synthesis steps are the same as in Example 1, except that (2-nitrovinyl)benzene is replaced by 1-bromo-2-(2-nitrovinyl)benzene to obtain a white solid.

[0056] White solid, m.p.182.1-182.9℃, 1H NMR (500MHz, CDCl 3 )δ8.61(d, J=8.0Hz,1H),7.83(dd,J=8,1Hz,1H),7.53-7.46(m,5H),7.41-7.37(m,2H),7.31-7.27( m,1H),7.13(s,1H),6.99(t,J=7.5Hz,2H),6.85(d,J=8Hz,1H),4.54(s,3H),3.93(s,3H). 13 C NMR (125MHz, CDCl 3 )δ142.6,141.2,141.1,140.8,137.7,134.7,132.8,131.5,129.3,127.5,124.4,124.2,123.9,123.8,122.8,121.2,120.5,119.5,119.1,114.4,108.9,108.8,106.5,102.9,35.0 , 29.7.HRMS(ESI):m / z calcd for(C 17 h 12 N 2 OS+H) + :439.0804; found: 439.0799.

Embodiment 3

[0057] Example 3 6-(3-bromophenyl)-5,12-dimethyl-5,12-dihydroindolo[3,2-a]carbazole

[0058]

[0059] The synthesis steps are the same as in Example 1, except that (2-nitrovinyl)benzene is replaced by 1-bromo-3-(2-nitrovinyl)benzene to obtain a white solid.

[0060] White solid, m.p.201.1-201.9℃, 1 H NMR (500MHz, CDCl 3 )δ8.60(d, J=8.5Hz, 1H), 7.83(t, J=2Hz, 1H), 7.66-7.64(m, 1H), 7.62-7.60(m, 1H), 7.51-7.48(m, 3H),7.43-7.37(m,2H),7.32-7.27(m,2H),7.12(s,1H),7.05-7.02(m,1H),4.53(s,3H),3.94(s,3H) . 13 C NMR (125MHz, CDCl 3 )δ144.1,141.5,141.1,140.7,138.1,134.7,132.3,131.4,130.6,129.9,128.3,124.4,123.9,123.7,122.8,122.5,121.1,121.0,119.3,119.2,113.8,108.9,106.3,103.3,35.0 , 29.6.HRMS(ESI):m / z calcd for(C 17 h 12 N 2 OS+H) + :439.0804; found: 439.0802.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com