A kind of photothermal dual curing black light-shielding resin composition and preparation method thereof

A resin composition, dual-curing technology, applied in the direction of epoxy resin glue, adhesive type, adhesive additive, etc. Guarantee the degree of pre-crosslinking and the effect of not easy to settle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

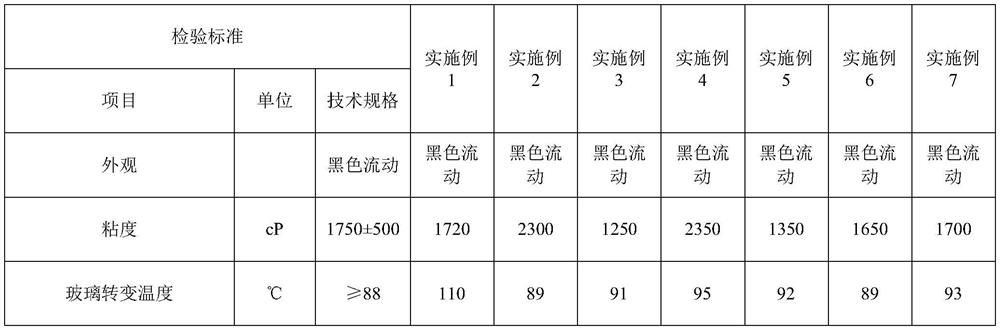

Examples

preparation example Construction

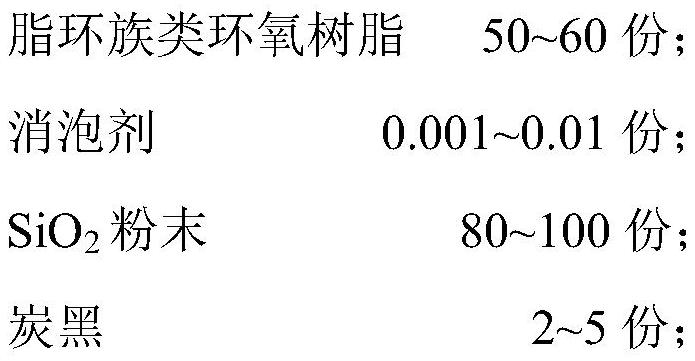

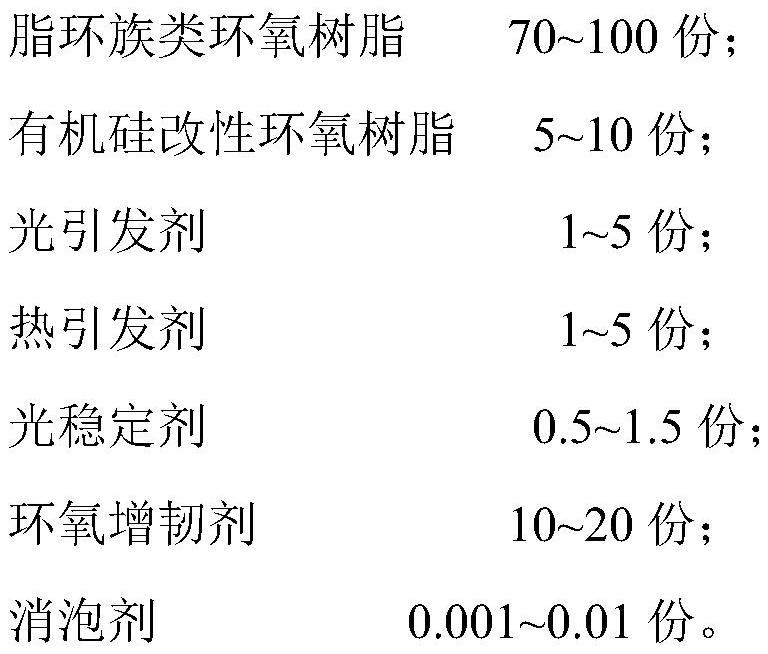

[0025] The preparation method of the above-mentioned photothermal dual-curing black light-shielding resin composition comprises the following steps: (a) mixing the alicyclic epoxy resin and the defoamer of the formulation amount, and then adding the SiO2 of the formulation amount 2 Powder and carbon black are mixed by ball milling to obtain the first masterbatch; (b) mixing the alicyclic epoxy resin, organosilicon modified epoxy resin, photoinitiator, thermal initiator and stabilizer of the formulation amount, and then Add epoxy toughener and defoamer and mix to obtain a second masterbatch; (c) mix the first masterbatch, the second masterbatch and defoamer in proportion, defoam and refrigerate for future use. Divide each component into the first masterbatch and the second masterbatch, etc. for separate batching, which is conducive to the full mixing of each material, and is conducive to the full mixing of each component to produce a synergistic effect: when the viscosity of the...

Embodiment 1

[0028] This embodiment provides a photothermal dual-curing black light-shielding resin composition and a preparation method thereof. The specific steps are as follows (clean the ball-milling jar and the ball-milling beads with ethanol before preparation, and wipe the ball-milling jar with a clean dry rag after draining the cleaning solution. and ball-milled beads, put in an oven at 80°C to remove residual ethanol):

[0029] (a) Configuration of the first masterbatch: Weigh 58.2g of cycloaliphatic epoxy resin 2021P and defoamer KSZ-660.005g for three-dimensional mixing (2000rmp, 200s, 2-3 times); add SiO 2 Powder (TSP-H10) 90g, carbon black #252.7g, after mixing evenly, transfer to a ball mill tank for ball mill mixing, the speed is 200rmp / min, turn for 4h, and set aside;

[0030] (b) Configuration of the second masterbatch: Weigh 74g of cycloaliphatic epoxy resin 2021P and 6.7g of silicone modified epoxy resin (JP-H26), stir and mix, then add photoinitiator (R-GEN 261 ) 2.3g,...

Embodiment 2

[0033] This embodiment provides a photothermal dual curing black light-shielding resin composition, the preparation method of which is basically the same as that in Example 1, the difference is: in step (c), the first masterbatch, the second masterbatch and the defoaming The mass ratio of the agent is 100:10:0.01.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com