Method for preparing carbon fiber/antimony sulfide composite negative electrode of lithium ion battery

A lithium ion battery and antimony sulfide technology, applied in the field of lithium ion batteries, can solve the problems of poor conductivity of the antimony sulfide negative electrode, change in the volume of lithium intercalation, complicated preparation process, etc., so as to improve the cycle and rate performance, shorten the transmission path and the preparation process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

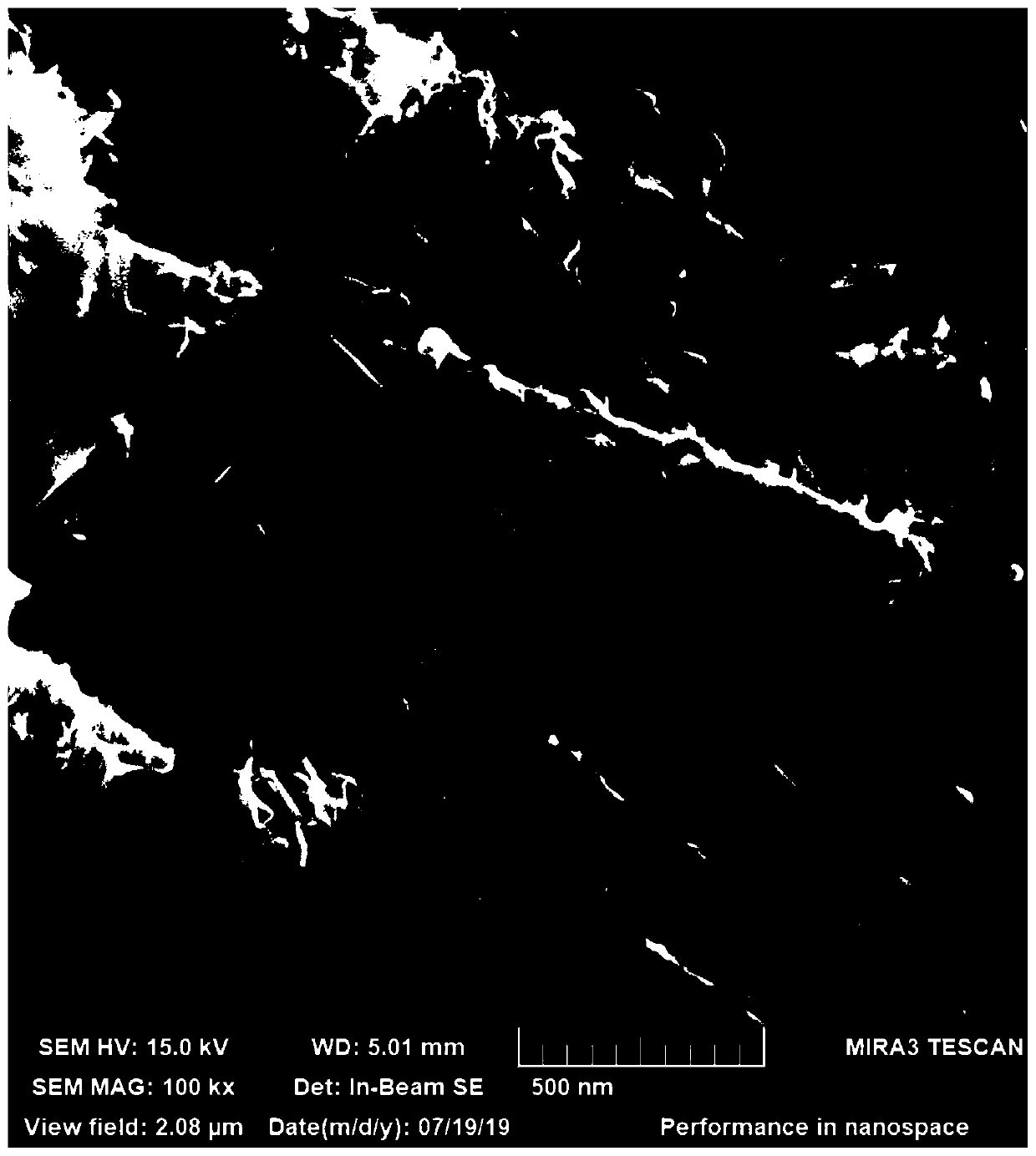

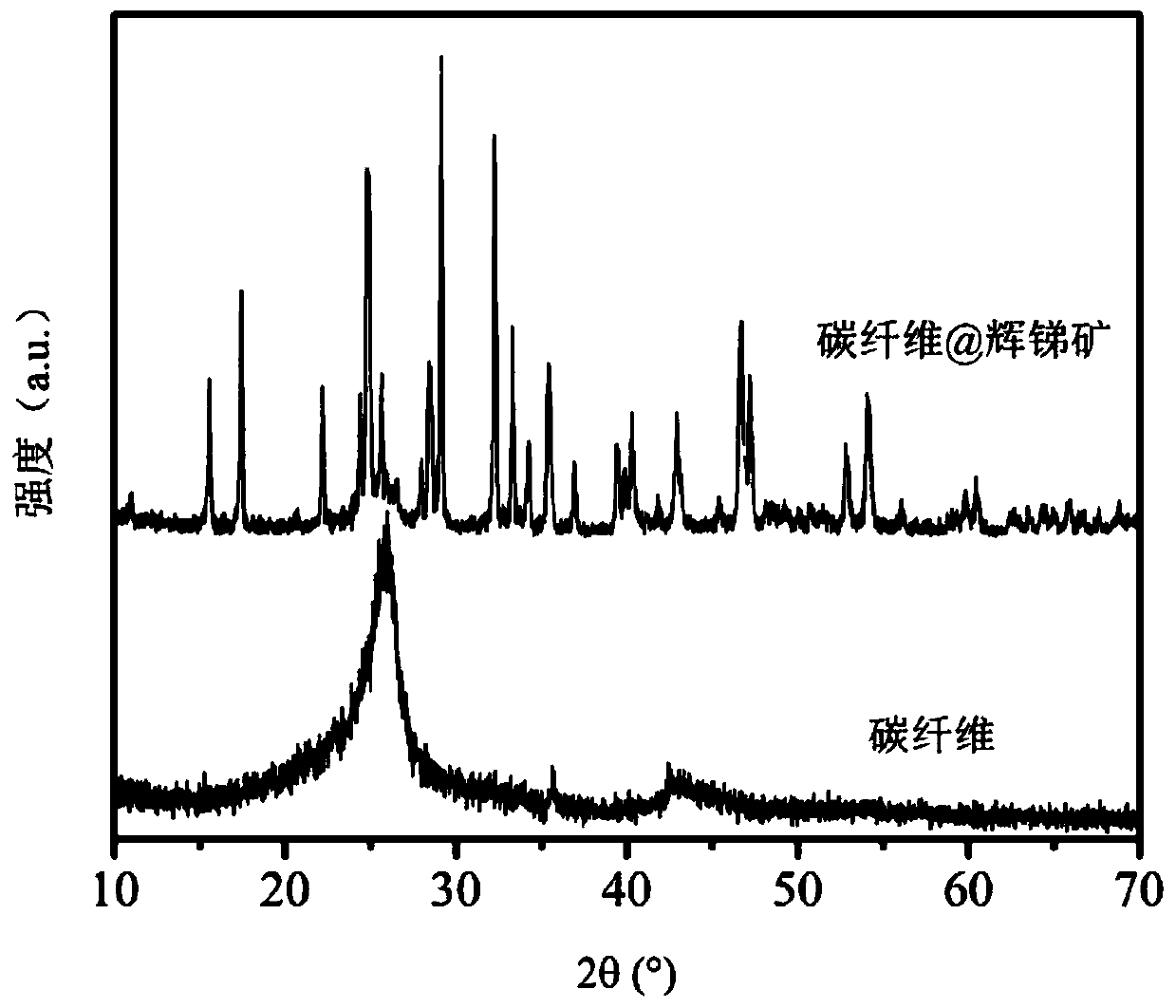

[0023] Weigh stibnite and carbon fiber according to the mass ratio of 1:1, add them to the ball milling tank, add ball milling beads according to the mass ratio of balls to material 20:1, and add ball milling media according to the mass ratio of alcohol to material 2:1. Start the ball mill, ball mill at 450r / min for 4 hours, and filter and dry after stopping to obtain the mixture. figure 1 It is a scanning electron microscope picture of the carbon fiber conductive matrix used, it can be seen that the diameter of the carbon fiber is 50-150 nm, and the length is 1-10 μm.

[0024] Place the above dry mixture in an argon atmosphere, raise the temperature to 620°C at 3°C / min, and keep it warm for 5 hours. After natural cooling, the molten stibnite adheres to the carbon fiber and recrystallizes to form nano-sized antimony sulfide grains , and thus obtain a carbon fiber@stibnite composite anode.

[0025] figure 2 The scanning electron microscope image of the carbon fiber@stibnite ...

Embodiment 2

[0028] Weigh high-purity antimony sulfide and carbon fiber according to the mass ratio of 80:20, add them to the ball milling tank, add ball milling beads according to the mass ratio of balls to material 15:1, ball mill in air medium at 600r / min for 1h, filter and dry after stopping, and obtain Mixture.

[0029] Place the above dry mixture in an argon atmosphere, raise the temperature to 580°C at 1°C / min, and keep it warm for 10 hours. After natural cooling, the molten stibnite adheres to the carbon fiber and recrystallizes to form nano-sized antimony sulfide grains , and thus obtain a carbon fiber@stibnite composite anode.

Embodiment 3

[0031] Weigh stibnite and carbon fiber according to the mass ratio of 10:90, add them to the ball milling tank, add ball milling beads according to the mass ratio of balls to material 20:1, ball mill in argon medium at 400r / min for 5h, filter and dry after stopping, and obtain Mixture.

[0032] Place the above dry mixture in an argon atmosphere, raise the temperature to 650°C at 10°C / min, and keep it warm for 5 hours. After natural cooling, the molten stibnite adheres to the carbon fiber and recrystallizes to form nano-sized antimony sulfide grains , and thus obtain a carbon fiber@stibnite composite anode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com