Method for producing lithium hydroxide from lithium-containing ore

A technology of lithium hydroxide and ore, which is applied in the direction of lithium oxide;/hydroxide, lithium halide, hydrogen chloride preparation, etc., can solve the problems of low economy and achieve the effect of improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

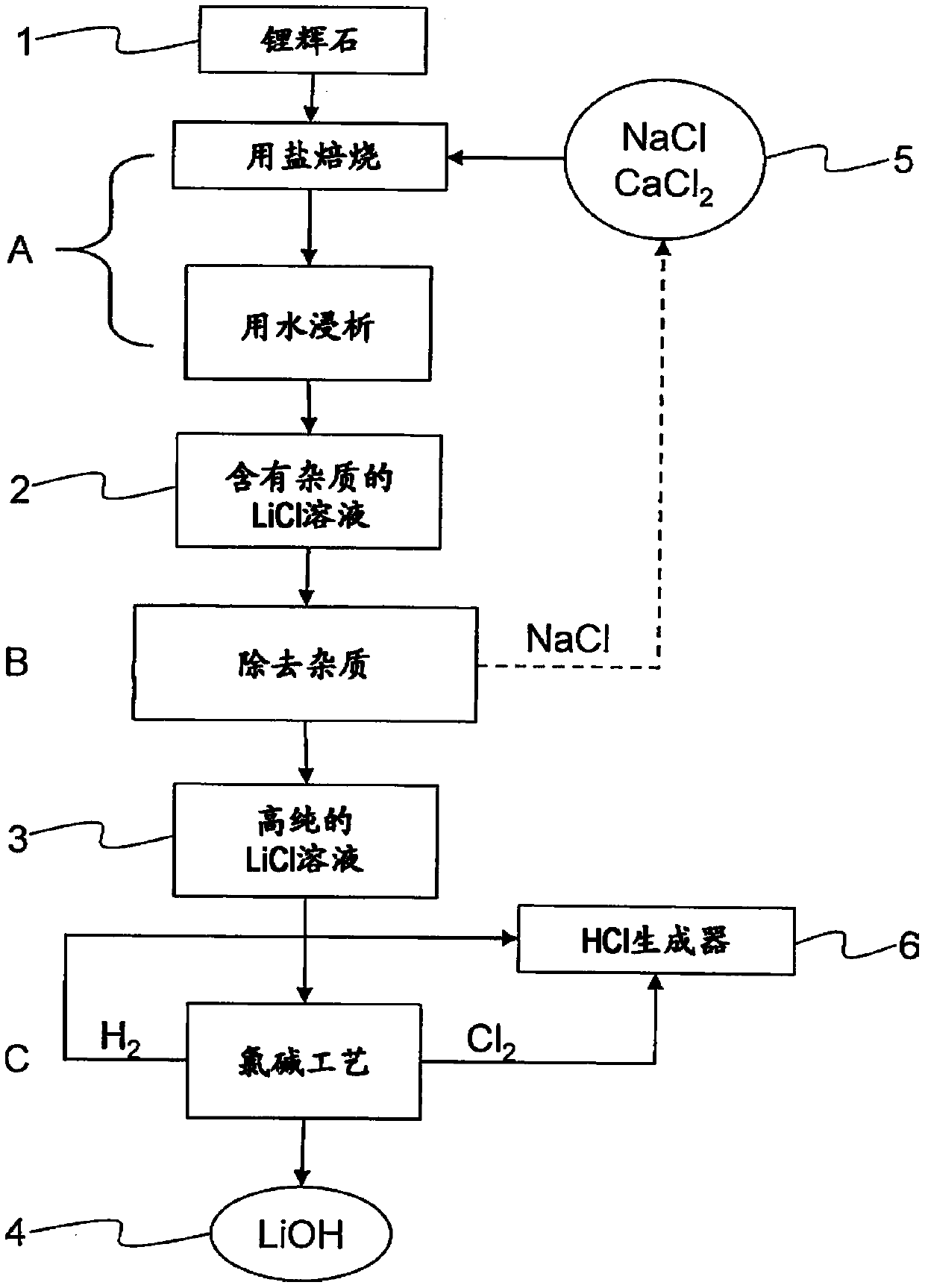

[0023] The drawing shows a process flow diagram of an exemplary process according to the invention for producing lithium hydroxide from lithium-containing ores and / or minerals and / or lithium-containing soils (1). According to this embodiment, lithium-containing mineral or soil (1) spodumene (LiAl[Si 2 o 6 ]) is used as a primary product for the preparation of lithium hydroxide (4) to obtain lithium hydroxide as the final product of the preparation process according to the invention for further use in battery applications, especially for rechargeable lithium-ion batteries. In particular, highly pure lithium hydroxide can be obtained with the aid of the production process according to the invention, whose total content of interfering impurity cations, such as calcium and magnesium, is below 150 ppb (parts per billion). Spodumene is present in lithium-containing ores (1), especially lepidolite. The preparation of lithium-containing ores and / or minerals (1) for further processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com