Bubble makeup holding foundation and preparation technology thereof

A preparation process, gouache technology, applied in the field of bubble makeup foundation and its preparation process, can solve the problems of consumers who are difficult to choose, the effect of oil-in-water is not enough, sticky, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the examples.

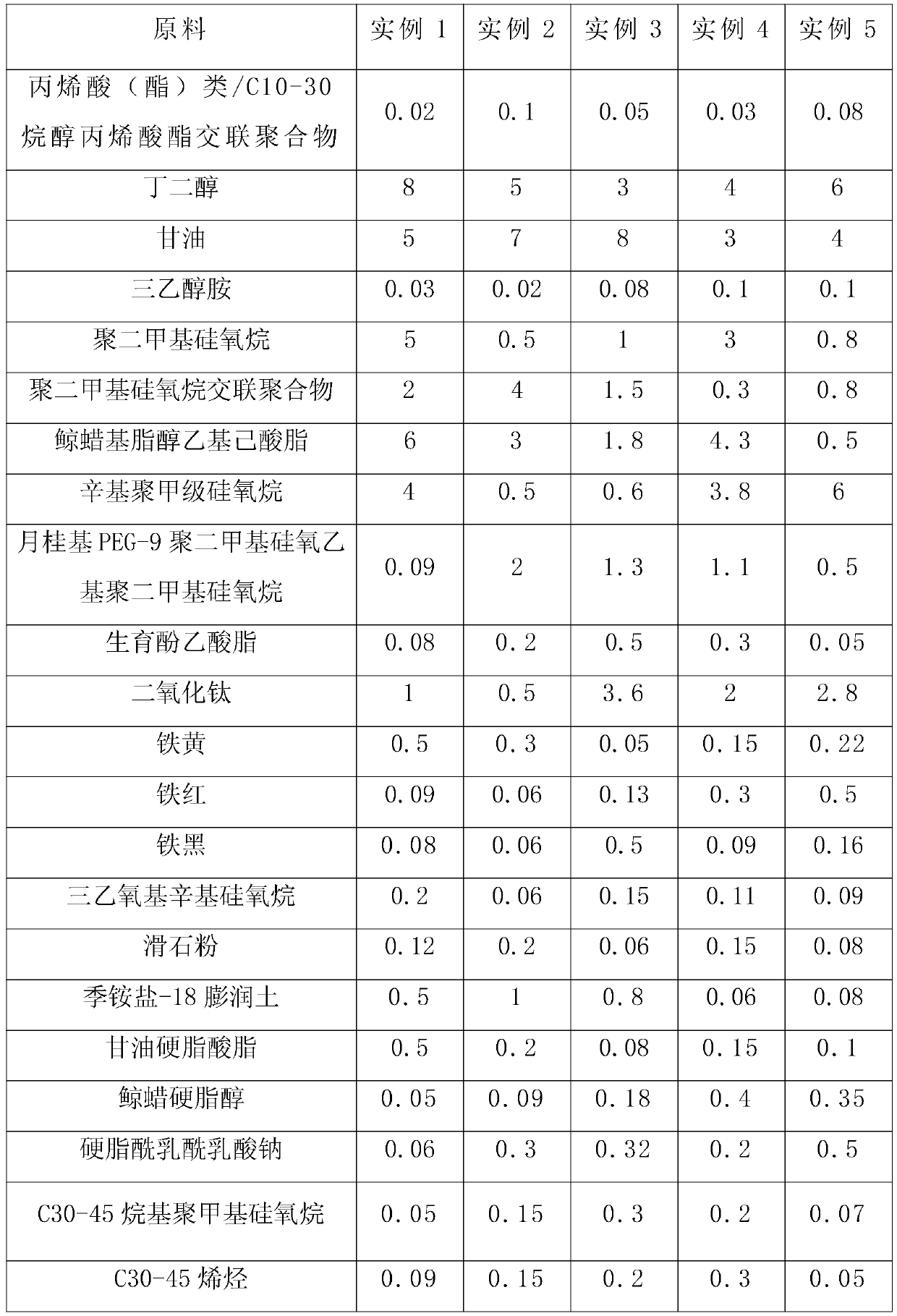

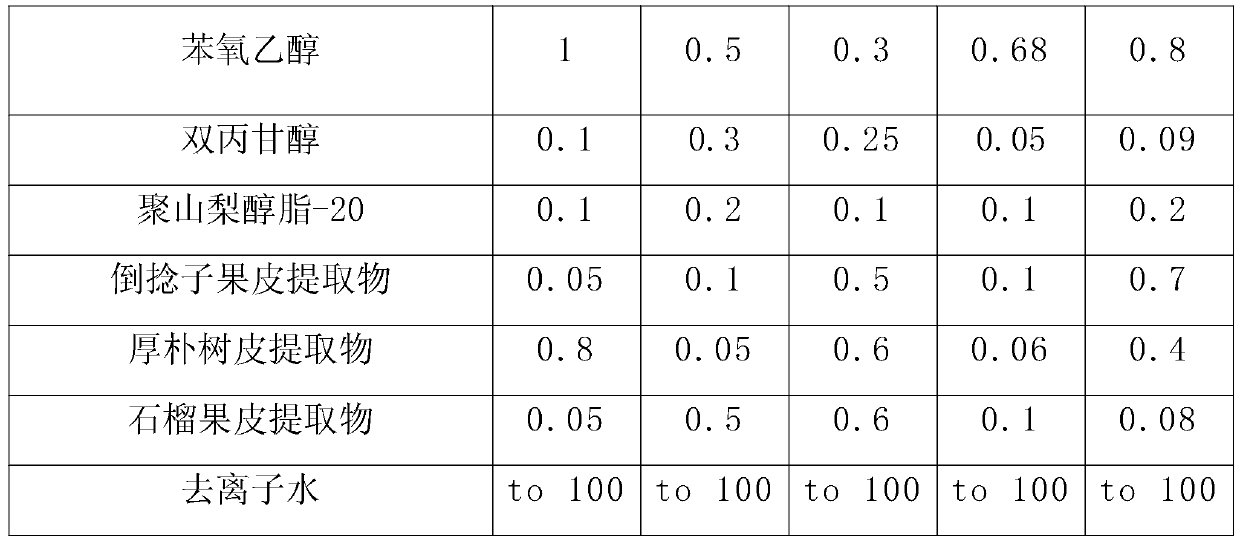

[0015] The foam foundation of the present invention comprises the following raw material components in mass fractions: deionized water 65%-80%, acrylic acid (ester) / C10-30 alkanol acrylate crosslinked polymer 0.02%-0.1% , butanediol 3%-8%, glycerin 3%-8%, triethanolamine 0.02%-0.1%, polydimethylsiloxane 0.5%-5%, polydimethylsiloxane crosslinked polymer 0.3 %-4%, Cetyl Alcohol Ethylhexanoate 0.5%-6%, Capryl Polymethicone 0.5%-6%, Lauryl PEG-9 Dimethicone Polydimethicone Methylsiloxane 0.05%-2%, Tocopherol Acetate 0.03%-0.5%, Titanium Dioxide 0.5%-4%, Iron Yellow 0.05%-0.5%, Iron Red 0.05%-0.5%, Iron Black 0.05%-0.5 %, triethoxycaprylyl siloxane 0.05%-0.2%, talc powder 0.05%-2%, quaternary ammonium salt-18 bentonite 0.05%-1%, glyceryl stearate 0.05%-0.5%, spermaceti Stearyl Alcohol 0.05%-0.5%, Sodium Stearoyl Lactyl Lactylate 0.05%-0.5%, C30-45 Alkyl Polymethicone 0.05%-0.3%, C30-4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com