Manufacturing method for inorganic non-metallic material 5G three-dimensional mobile phone antenna through laser engraving

An inorganic non-metal, mobile phone antenna technology, applied in metal material coating process, liquid chemical plating, coating and other directions, can solve problems such as antenna design, achieve the effect of enhancing antenna gain, reducing high frequency loss, and preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

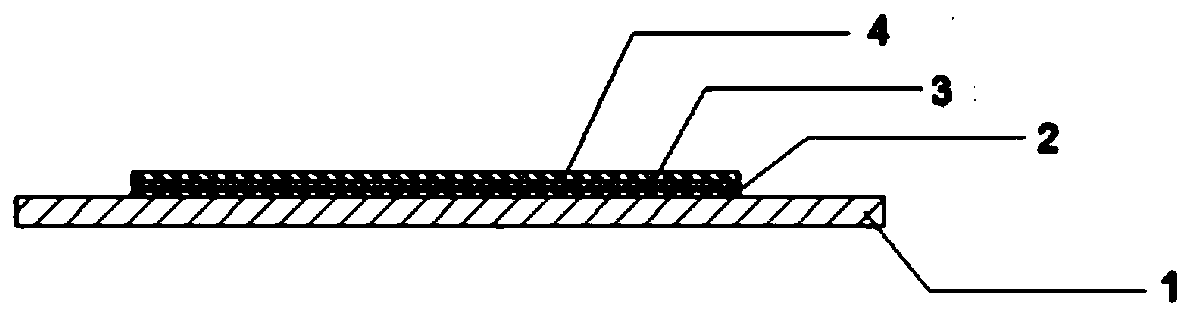

[0031] The manufacturing method of the 5G three-dimensional laser engraved mobile phone antenna on the surface of the glass substrate, the process includes: laser, water washing, minhua, water washing, activation, water washing, electroless Cu plating, water washing, electroless Ni plating, drying, and post-plating treatment. The main steps are as follows:

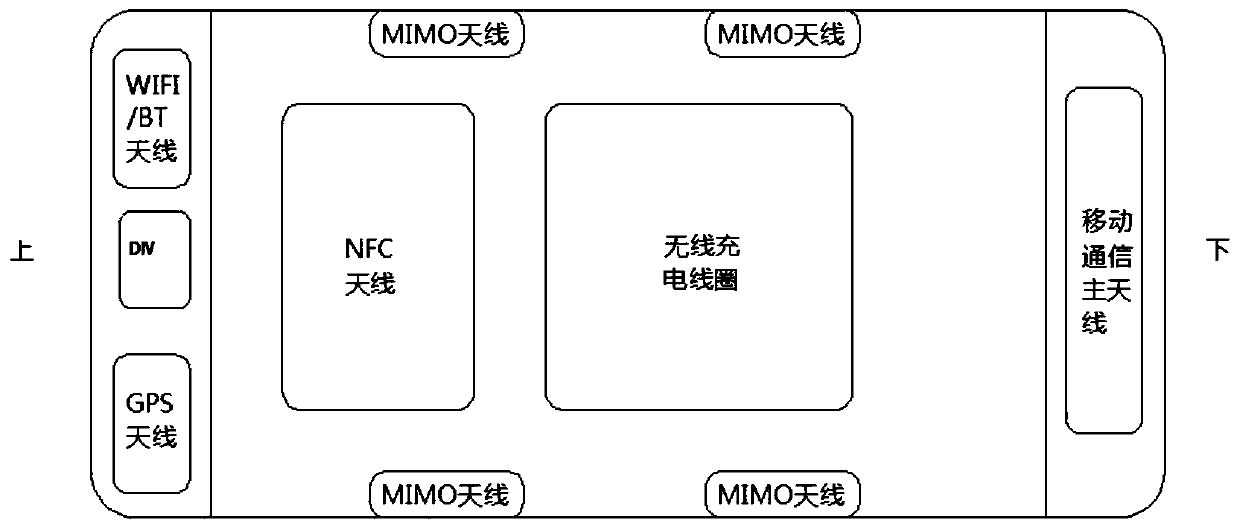

[0032] (1) Laser: After cleaning the smooth surface of the glass substrate, use ND:YVO 4 The ultraviolet laser is used for lasing. During the lasing process, the glass substrate needs to be reversed to etch the wiring and shape of the main communication antenna. The diameter of the laser engraving spot is 0.05mm, forming a radium engraving area with a rough texture on the frosted surface.

[0033] The setting parameters of the laser engraving machine are: wavelength 355nm, light output power 20KHz, pulse width 2us, spot moving speed 100mm / s, scanning line spacing 0.07mm, light output power 3W.

[0034] (2) Washing: Put th...

experiment example 2

[0047] The manufacturing method of the 5G three-dimensional laser engraved mobile phone antenna on the surface of the glass substrate, the process includes: laser, water washing, sensitization + activation, water washing, electroless Cu plating, water washing, electroless Ni plating, water washing, electroless gold plating, drying, post-plating treatment, specifically Proceed as follows:

[0048] Steps (1) and (2) in this embodiment are the same as in Embodiment 1.

[0049] (3) Sensitization + activation: in the collagen palladium acidic solution, the Pd in the collagen palladium activation solution 2+ and Sn 2+ It will react to generate adsorptive colloidal palladium particles, and absorb excess Sn in the solution 2+ , exists in colloidal form. The glass substrate with water film completed in the previous step is immersed in the collagen palladium activation solution. The radium engraved area first absorbs the divalent tin ions in the solution, and then absorbs the chlor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com