Low-thermal-resistance and low-temperature luminescent powder layer LED

A technology of light-emitting diodes and luminescent powder, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of complex process, high cost, and accelerated light decay, and achieve uniform luminescent powder layer, simple manufacturing process, and simple coating process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

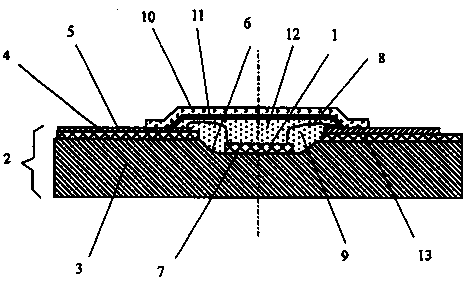

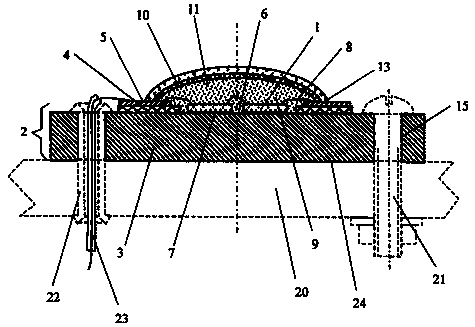

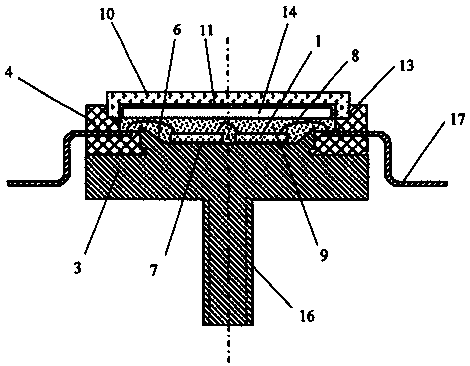

[0021] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 It is a schematic structural diagram of an embodiment of the power light emitting diode of the present invention. It includes at least one light-emitting diode chip 1, at least one metal-based circuit board 2, the metal base 3 of the circuit board 2 is a high thermal conductivity plate such as copper or aluminum, and an insulating layer 4 and a conductive layer 5 are arranged on the metal base. Chip place does not have insulating layer 4 and conductive layer 5, is a light reflection surface or light reflection bowl 6 ( figure 1 Shown is an example of a light reflection bowl), the light-emitting diode chip 1 is fixed on the metal base 3 with high thermal conductivity glue 7, the electrodes of the light-emitting diode chip are connected to the conductive layer 5 through the lead wire 8, and the conductive layer 5 is used to connect the external surface at the same ti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap