Preparation method of two-dimensional ferroferric oxide Fenton catalyst and application thereof in degradation of aminobenzene sulfonic acid-containing wastewater

A technology of ferric tetroxide and catalyst, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., to achieve high dispersibility, simple synthesis process and easy repeatability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11

[0061] According to the preparation method of the catalyst described in claims 2 to 8, a two-dimensional ferric oxide-based Fenton catalyst is prepared, and the degradation effect of aminobenzenesulfonic acid is investigated.

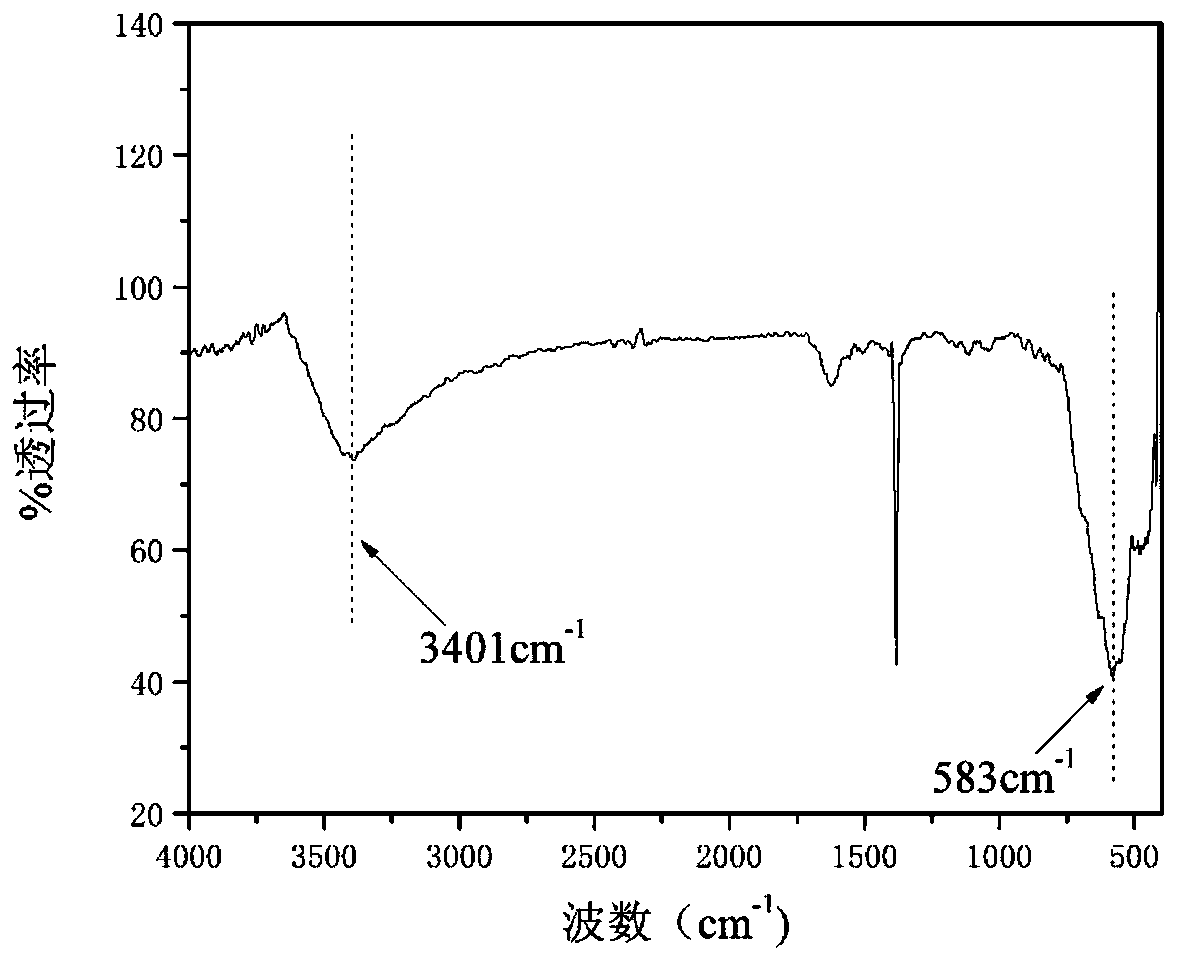

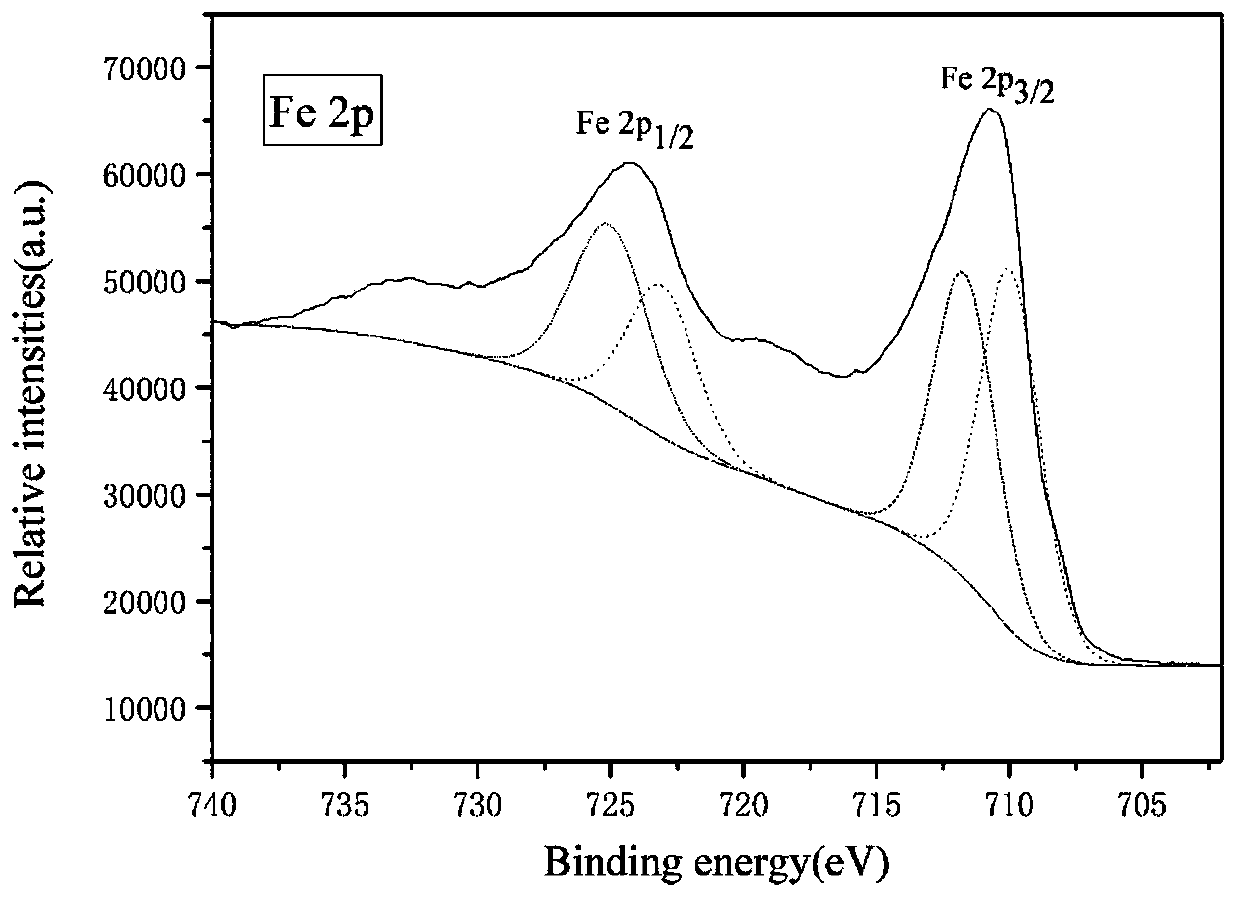

[0062] (1) Preparation of two-dimensional ferric oxide Fenton-like catalyst

[0063] 1) First, add an appropriate amount of concentrated sulfuric acid to 200mL deoxygenated double-distilled water to create an acidic environment to maintain the stability of the iron-salt mixed solution. Then accurately weigh 0.05mol FeSO 4 particles and 0.1mol FeCl 3 The particles were sequentially dissolved in the above-mentioned deoxygenated twice distilled water to prepare Fe 2+ and Fe 3+ The mixed solution of Fe 2+ : Fe 3+ = 1:2 (ratio of substances), sealed and stored after dissolution is complete.

[0064] 2) Use 200mL deoxygenated twice distilled water, according to Fe 2+ : Fe 3+ :OH - =1:2:(9~10) (mass ratio of substances) added to prepare NaOH solution ...

Embodiment 12~15

[0070] Using the catalyst obtained in Example 3, a recycling performance experiment was carried out to investigate the relationship between the number of cycles of the two-dimensional ferric oxide-based Fenton catalyst and the degradation effect of aminobenzenesulfonic acid (see Table 2).

[0071] Table 2

[0072]

[0073] It can be seen that the two-dimensional catalyst obtained in the present invention has good cycle stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com