Porous photo-thermal film with salt precipitation resistance and preparation and application thereof

A porous membrane and performance technology, applied in the field of solar seawater desalination, can solve the problems of low light absorption efficiency, wide, and can only absorb ultraviolet light, etc., achieve high light absorption performance, strong operability, and prevent the effect of salt precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Step 1: Base Treatment

[0039] Sonicate 100-mesh Ti mesh (4cm*4cm, can be cut as needed) in acetone, alcohol, and deionized water for 30 minutes to remove surface impurities.

[0040] The second step: TiO 2 / Ti porous membrane preparation

[0041] Put the Ti grid treated in the above steps into 10M NaOH solution, keep it warm at 120°C for 12h for hydrothermal synthesis reaction, then perform ion exchange in 1M HCl solution for 10min, and finally anneal at 500°C for 0.5h, the heating rate 2°C·min -1 , and finally obtain TiO 2 / Ti hierarchical hole structure photothermal film, micropore 150um, nanopore about 500-600nm.

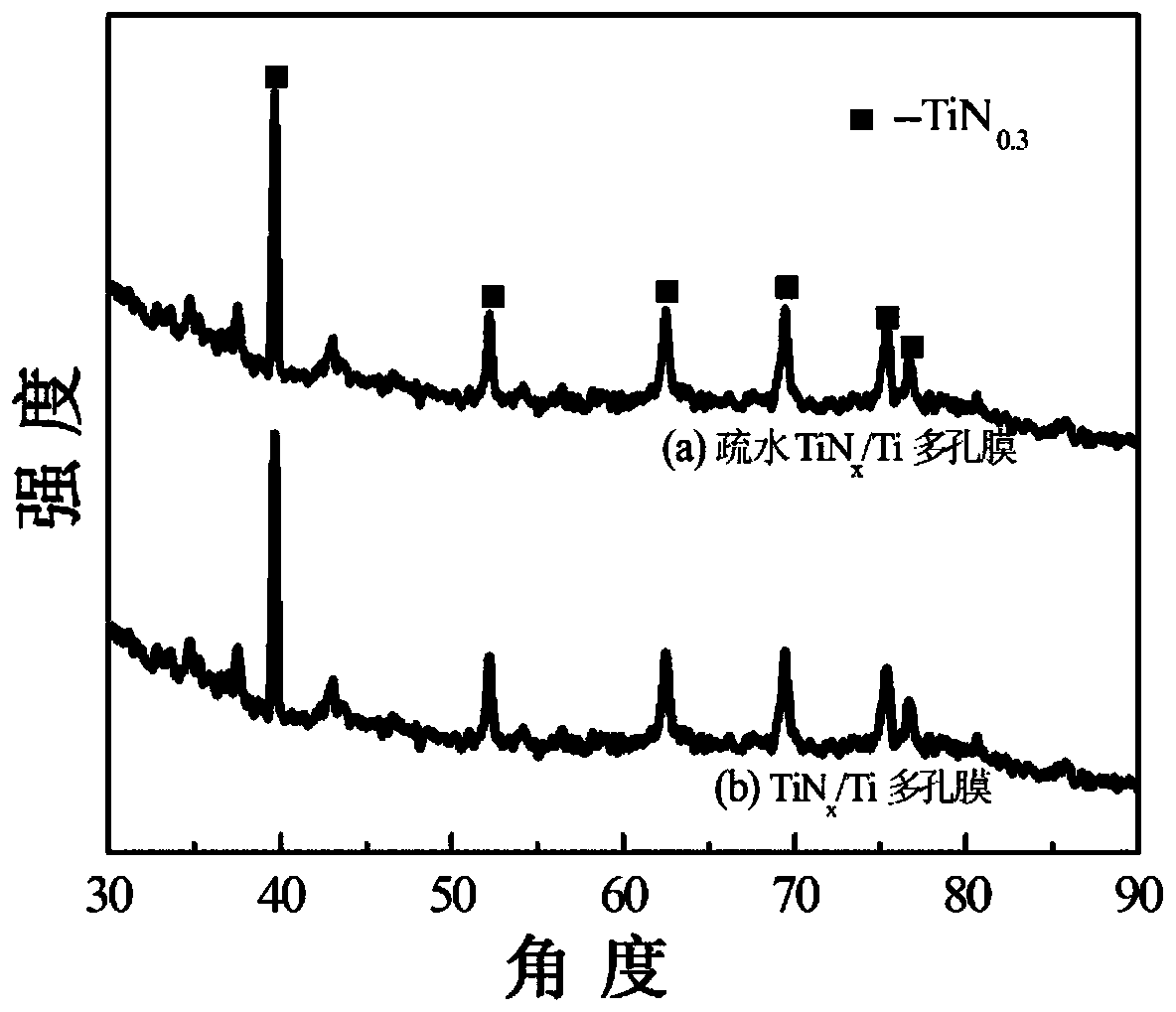

[0042] The third step: TiN x / Ti porous membrane preparation

[0043] TiO prepared by the above steps 2 / Ti porous membrane was nitrided at 1000°C to obtain TiN x / Ti porous membrane. The processing time is 7h, the working gas is NH 3 , air flow 10ml·min -1 .

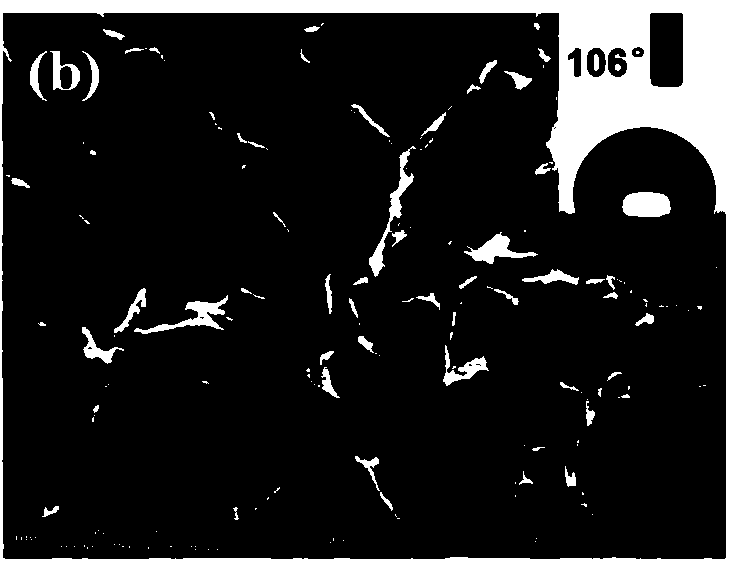

[0044] Step Four: Hydrophobic Modification

[0045] The TiN prepared by the above...

Embodiment 2

[0050] Step 1: Base Treatment

[0051] Sonicate the 50-mesh Ti mesh (4cm*4cm, can be cut as needed) in acetone, alcohol, and deionized water for 30 minutes to remove surface impurities.

[0052] The second step: TiO 2 / Ti porous membrane preparation

[0053] Put the Ti mesh treated in the above steps into 10M NaOH solution, keep it warm at 120°C for 2h for hydrothermal synthesis reaction, then perform ion exchange in 1M HCl solution for 10min, and finally anneal at 500°C for 0.5h, the heating rate 2°C·min -1 , and finally obtain TiO 2 / Ti hierarchical hole structure photothermal film, the micropore is 270um, and the nanopore is about 100-200nm.

[0054] The third step: TiN x / Ti porous membrane preparation

[0055] TiO prepared by the above steps 2 / Ti porous membrane was nitrided at 1000°C to obtain TiN x / Ti porous membrane. The processing time is 7h, the working gas is NH 3 , air flow 10ml·min -1 .

[0056] Step Four: Hydrophobic Modification

[0057] The TiN p...

Embodiment 3

[0061] Step 1: Base Treatment

[0062] Sonicate 200-mesh Ti mesh (4cm*4cm, can be cut as needed) in acetone, alcohol, and deionized water for 30 minutes to remove surface impurities.

[0063] The second step: TiO 2 / Ti porous membrane preparation

[0064] Put the Ti net treated in the above steps into 10M NaOH solution, keep it warm at 120°C for 6h for hydrothermal synthesis reaction, then conduct ion exchange in 1M HCl solution for 10min, and finally anneal at 500°C for 0.5h, the heating rate 2°C·min -1 , and finally obtain TiO 2 / Ti hierarchical hole structure photothermal film, the micropore is 75um, and the nanopore is about 200-300nm.

[0065] The third step: TiN x / Ti porous membrane preparation

[0066] TiO prepared by the above steps 2 / Ti porous membrane was nitrided at 800°C to obtain TiN x / Ti porous membrane. The processing time is 10h, the working gas is NH 3 , air flow 10ml·min -1 .

[0067] Step Four: Hydrophobic Modification

[0068] The TiN prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com