Resourceful treatment system and treatment method for sodium carboxymethyl cellulose production wastewater

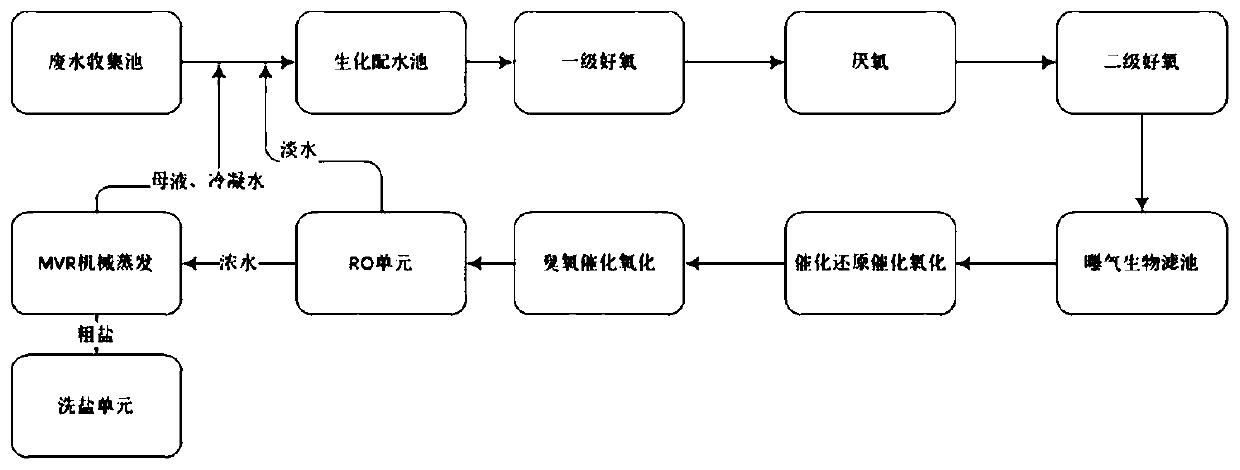

A technology for sodium carboxymethyl cellulose and waste water production, which is applied in water/sewage treatment, chemical instruments and methods, heating water/sewage treatment, etc. Realize problems such as salt and water resources, and achieve the effects of low cost, simple operation and resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Select a carboxymethyl cellulose production wastewater in Shandong, COD is 40 g / L, TDS is 98 g / L, of which sodium chloride accounts for 85 g / L. The specific operation is as follows:

[0049] (1) Biochemical water distribution: After coagulation and sedimentation of high-salt and high-organic waste water, it is pumped into the distribution tank, and the COD of the wastewater is adjusted to 8g / L, and the TDS is 18g / L. mechanical evaporation of condensed water;

[0050] (2) First-class aerobic for salt-tolerant bacteria + anaerobic for salt-tolerant bacteria + second-level aerobic for salt-tolerant bacteria + aerated biological filter for salt-tolerant bacteria: biochemical water distribution enters first-level aerobic for salt-tolerant bacteria + anaerobic for salt-tolerant bacteria Oxygen + salt-tolerant bacteria secondary aerobic + salt-tolerant bacteria aerated biological filter, in which the residence time of the first-level aerobic and salt-tolerant bacteria anaerob...

Embodiment 2

[0058] Select a carboxymethyl cellulose production wastewater in Jiangsu, COD is 37g / L, TDS is 75g / L, of which sodium chloride accounts for 70g / L. Concrete implementation steps are roughly the same as embodiment 1, the difference is:

[0059] (1) COD of biochemical distribution water is 7.5g / L, TDS is 1.6g / L;

[0060] (2) The pH of the feed water for catalytic reduction and catalytic oxidation is adjusted to 2;

[0061] (3) The dosage of hydrogen peroxide in the process of ozone catalytic oxidation is 0.2‰, and the residence time is 30min.

[0062] Under the above operating conditions, when the biochemical influent water is 7.5g / L, the effluent COD of ozone catalytic oxidation after the above steps Cr Within 100mg / L, after RO treatment, the water quality index of RO effluent is: COD Cr Less than 15mg / L, Cl - Less than 30mg / L, conductivity less than 50μs / cm, the water quality is due to tap water, which can be used for industrial reuse; the purity of sodium chloride is great...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com