Packaging structure for improving reliability of SESAM all-fiber mode-locked laser oscillator

A packaging structure and mode-locked laser technology, which is applied in the laser field, can solve the problems of low maintenance efficiency, reduced anti-damage threshold of saturable absorbing mirrors, and difficulties, so as to improve stability and reliability, enhance anti-environmental interference characteristics, and facilitate Effect of replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

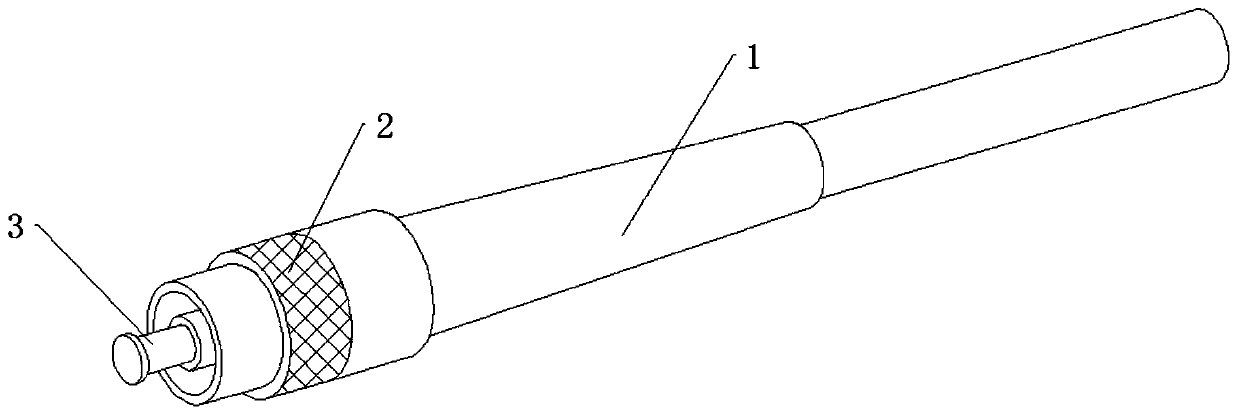

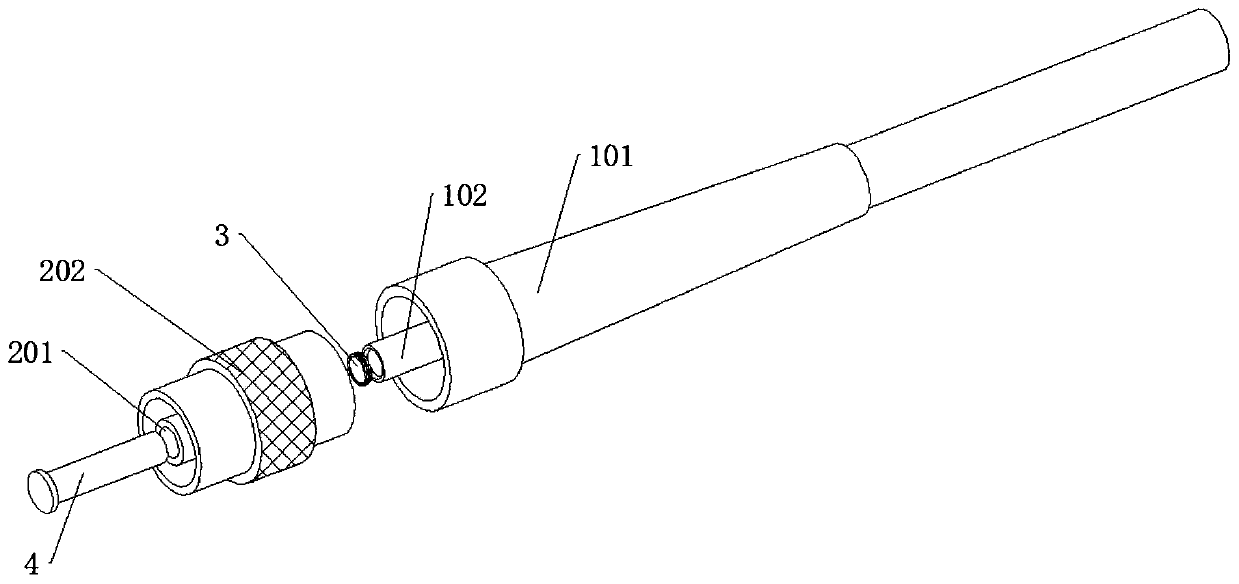

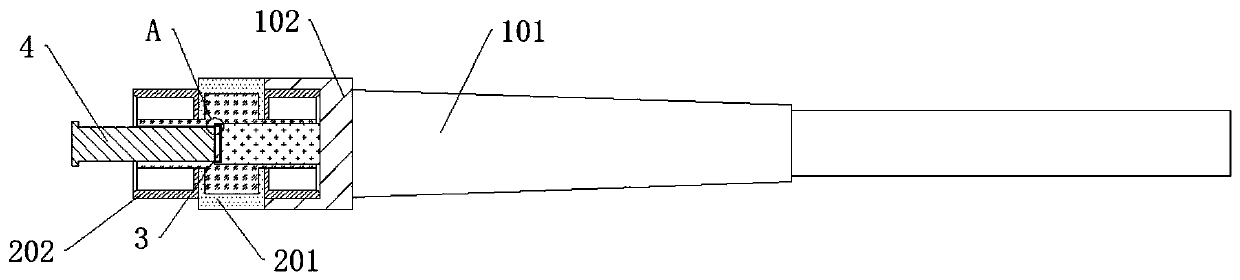

[0037] See figure 1 , figure 2 with image 3 , A packaging structure that improves the reliability of the SESAM all-fiber mode-locked laser oscillator, including the SESAM packaging structure. The SESAM packaging structure includes an optical fiber jumper 1, which includes a polarization maintaining fiber 101 and a stud ferrule 102. The jumper 101 is a single-mode fiber jumper with a length of 1-1.5m. The core diameter of the fiber jumper 101 is 5-6μm. The stud core 102 is equipped with an optical fiber that matches the protection ring 301. The optical fiber is installed in the screw. In the cylindrical ferrule 102, the end of the optical fiber close to the semiconductor saturable absorption mirror is a plane end with an angle of 0°. The stud ferrule 102 is threadedly connected with a conversion sleeve 2. The conversion sleeve 2 in this solution is FC / PC to FC / PC matching sleeve, the conversion sleeve 2 includes a shell 201 and an inner tube 202. The surface of the shell 201 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Core diameter | aaaaa | aaaaa |

| Reflection bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com