Waterborne polyurethane resin and preparation method thereof and waterborne baking paint

A water-based polyurethane and resin technology, applied in the direction of climate sustainability, sustainable manufacturing/processing, chemical industry, etc., can solve the problems of partial film layer peeling off water resistance, poor water resistance, substandard, etc., to improve storage stability, Enhances water solubility and reduces flash rust problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

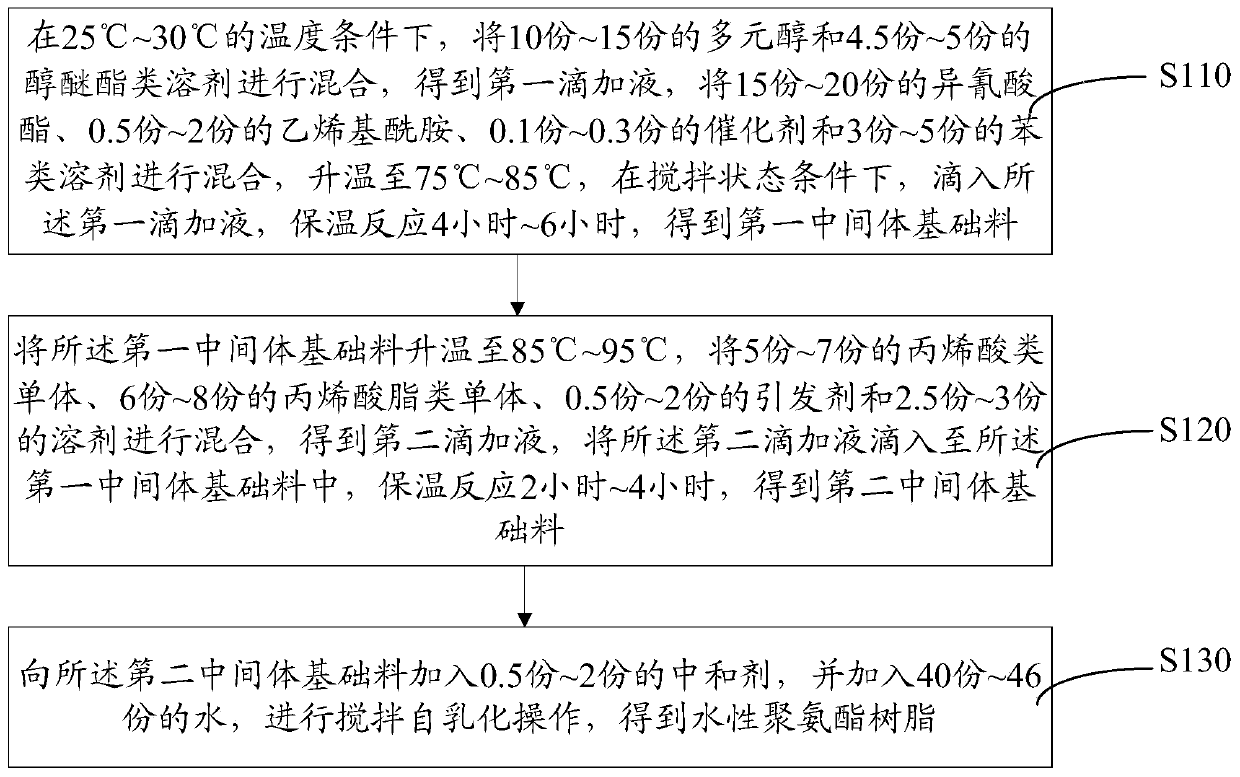

[0039] see figure 1 , the preparation method of aqueous polyurethane resin in one embodiment, comprises the steps:

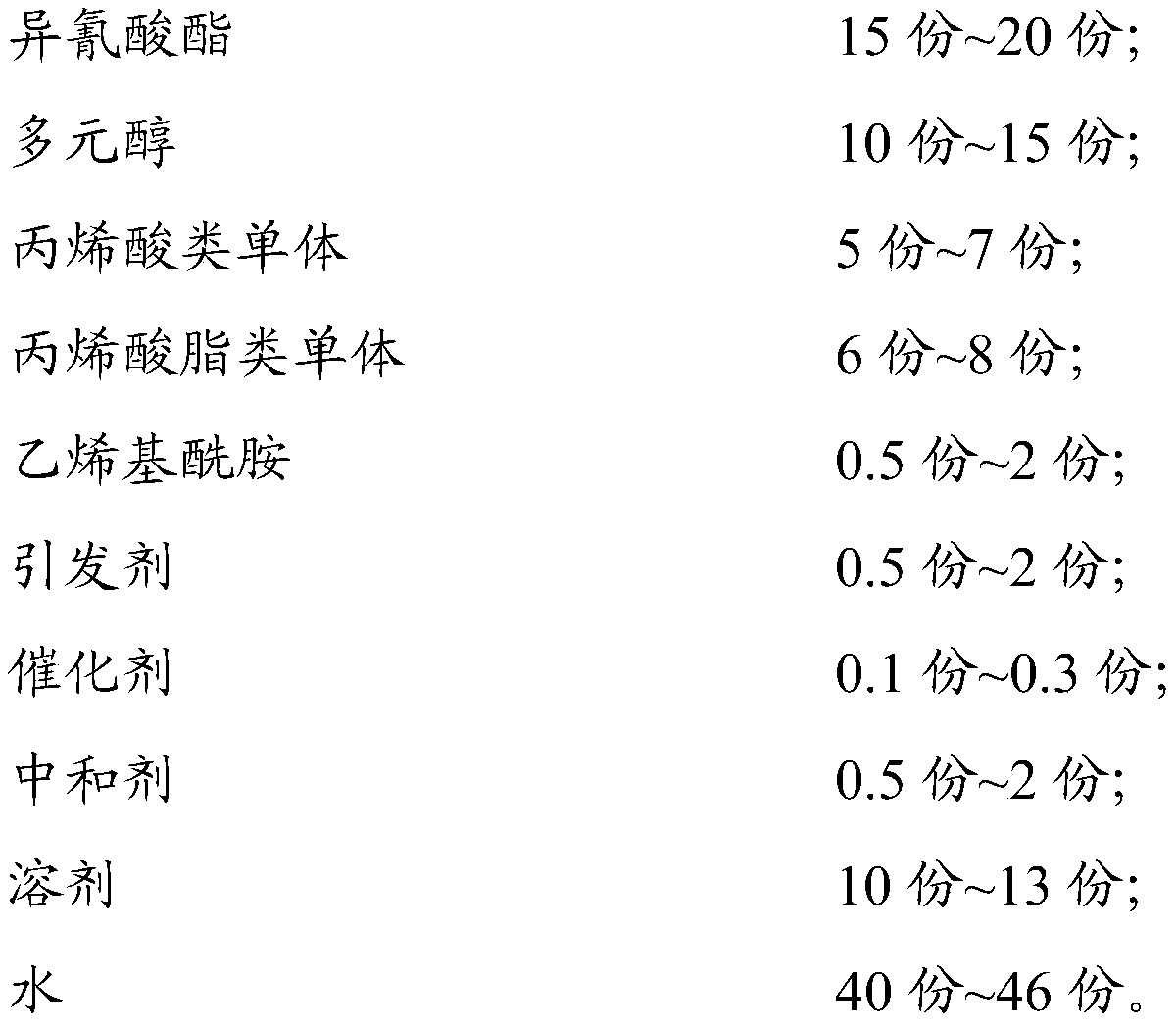

[0040] S110. Under the temperature condition of 25°C-30°C, mix 10-15 parts of polyhydric alcohol and 4.5-5 parts of alcohol ether ester solvent to obtain the first drop solution, and mix 15-20 parts of Mix isocyanate, 0.5 to 2 parts of vinylamide, 0.1 to 0.3 parts of catalyst and 3 to 5 parts of benzene solvent, heat up to 75°C to 85°C, and drop into the The first dropwise solution is kept for 4 hours to 6 hours for reaction to obtain the first intermediate base material.

[0041] When the above-mentioned water-based polyurethane resin is obtained by reacting isocyanate and polyol to obtain polyurethane, vinylamide is added together to participate in the reaction to form urethane groups and urea groups, especially the urea groups are non-hydrophilic groups. When the above-mentioned water-based polyurethane After the water-based baking varnish prepared with res...

Embodiment 1

[0058] Under the temperature condition of 28 ℃, the methyl propanediol of 60g and the neopentyl glycol of 75g and the propylene glycol methyl ether acetate of 45g are mixed, obtain the first dripping liquid, the toluene diisocyanate of 200g, the acrylamide of 3g, 8g of methacrylamide, 7g of methylolacrylamide, 2.5g of dibutyl dilaurate and 35g of trimethylbenzene were mixed, the temperature was raised to 85°C, and the first Add liquid dropwise, heat preservation reaction for 5 hours, obtain the first intermediate base material;

[0059] The temperature of the first intermediate base material was raised to 95°C, and 65g of methacrylic acid, 25g of butyl acrylate, 17g of isooctyl acrylate, 18g of ethyl acrylate, 16g of methyl acrylate, 12g of peroxide Benzoyl and 26g of trimethylbenzene were mixed to obtain the second dripping solution, which was dripped into the first intermediate base material, and kept for 3.5 hours to obtain the second intermediate base material. material; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com