A kind of polymer phosphorus-silicon flame retardant and preparation method thereof

A technology of silicon flame retardant and polymer, which is applied in the field of polymer phosphorus-silicon flame retardant and its preparation, can solve the problems of compatibility of polymer materials that are not resistant to hydrolysis, hindering reburning, and low corrosion , to achieve the effects of convenient control, improved compatibility and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

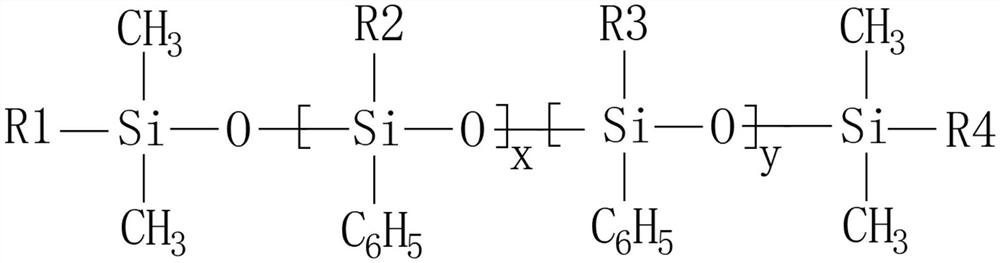

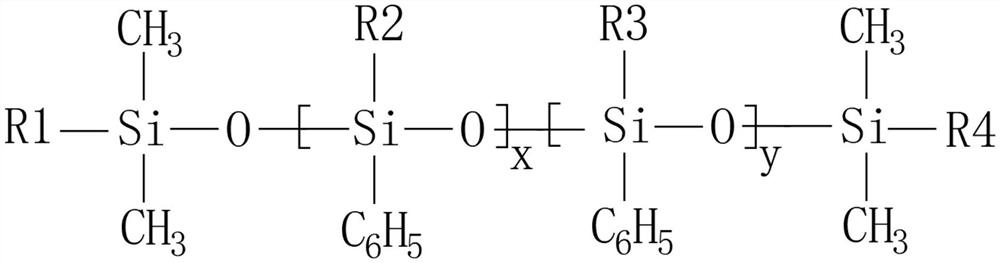

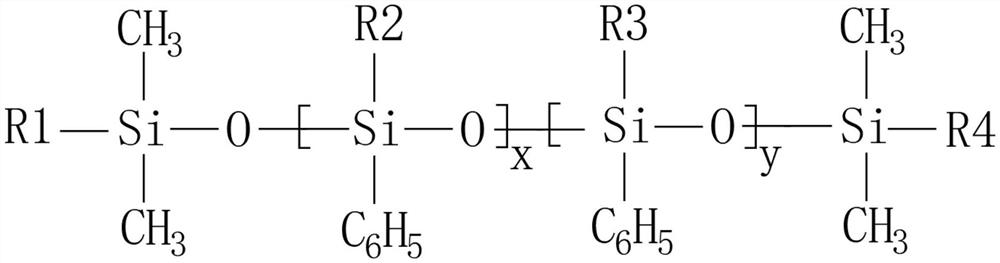

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of a polymer phosphorus-silicon flame retardant, comprising the steps of:

[0034] (S1), take the flame retardant intermediate DOPO and heat it to a molten state, then add phenylvinyl silicone oil to the molten flame retardant intermediate DOPO and mix, raise the temperature to initiate the reaction for 13 hours, and obtain phenylvinyl silicone oil grafted with DOPO ;

[0035] (S2), mix 0.25 parts of aromatic vinyl monomers and 0.2 parts of phenylvinyl silicone oil grafted with DOPO obtained in step (S1) in molar parts, then add 33 parts of water and 0.03 parts of release agent and mix uniformly, Then add initiator A, then raise the temperature to 78°C under continuous stirring conditions, initiate the reaction for 7 hours, then filter, wash, and dry to obtain a polymer phosphorus-silicon-containing flame retardant.

[0036] In the step (S1), the molar fraction of the vinyl group of the phenyl vinyl silicone oil is twice the molar fraction of the f...

Embodiment 2

[0047] A preparation method of a polymer phosphorus-silicon flame retardant, comprising the steps of:

[0048] (S1), take the flame retardant intermediate DOPO and heat it to a molten state, then add phenylvinyl silicone oil to the molten flame retardant intermediate DOPO and mix, raise the temperature to initiate the reaction for 10 hours, and obtain phenylvinyl silicone oil grafted with DOPO ;

[0049] (S2), mix 0.2 part of aromatic vinyl monomer and 0.1 part of phenylvinyl silicone oil grafted with DOPO obtained in step (S1) in molar parts, then add 30 parts of water and 0.01 part of release agent and mix uniformly, Then add initiator A, then raise the temperature to 70°C under continuous stirring conditions, initiate the reaction for 8 hours, then filter, wash, and dry to obtain a polymer phosphorus-silicon-containing flame retardant.

[0050] In the step (S1), the molar fraction of the vinyl group of the phenyl vinyl silicone oil is 1.8 times the molar fraction of the fl...

Embodiment 3

[0061] A preparation method of a polymer phosphorus-silicon flame retardant, comprising the steps of:

[0062] (S1), take the flame retardant intermediate DOPO and heat it to a molten state, then add phenylvinyl silicone oil to the molten flame retardant intermediate DOPO and mix, raise the temperature to initiate the reaction for 15 hours, and obtain phenylvinyl silicone oil grafted with DOPO ;

[0063] (S2), mix 0.3 part of aromatic vinyl monomer and 0.3 part of phenylvinyl silicone oil grafted with DOPO obtained in step (S1) in molar parts, then add 35 parts of water and 0.05 part of release agent and mix uniformly, Then add initiator A, then raise the temperature to 85°C under continuous stirring, initiate the reaction for 8 hours, then filter, wash, and dry to obtain a high molecular phosphorus-silicon-containing flame retardant.

[0064] In the step (S1), the molar fraction of the vinyl group of the phenyl vinyl silicone oil is 3.0 times the molar fraction of the flame ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com