Methanol fuel performance improver for M100 vehicle and preparation method thereof

A technology for fuel performance and methanol for vehicles, which is applied in fuel additives, fuels, liquid carbon-containing fuels, etc. It can solve problems such as emulsification, corrosion swelling, high-temperature air resistance, etc., and achieve good stability, good water resistance, and good mutual solubility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

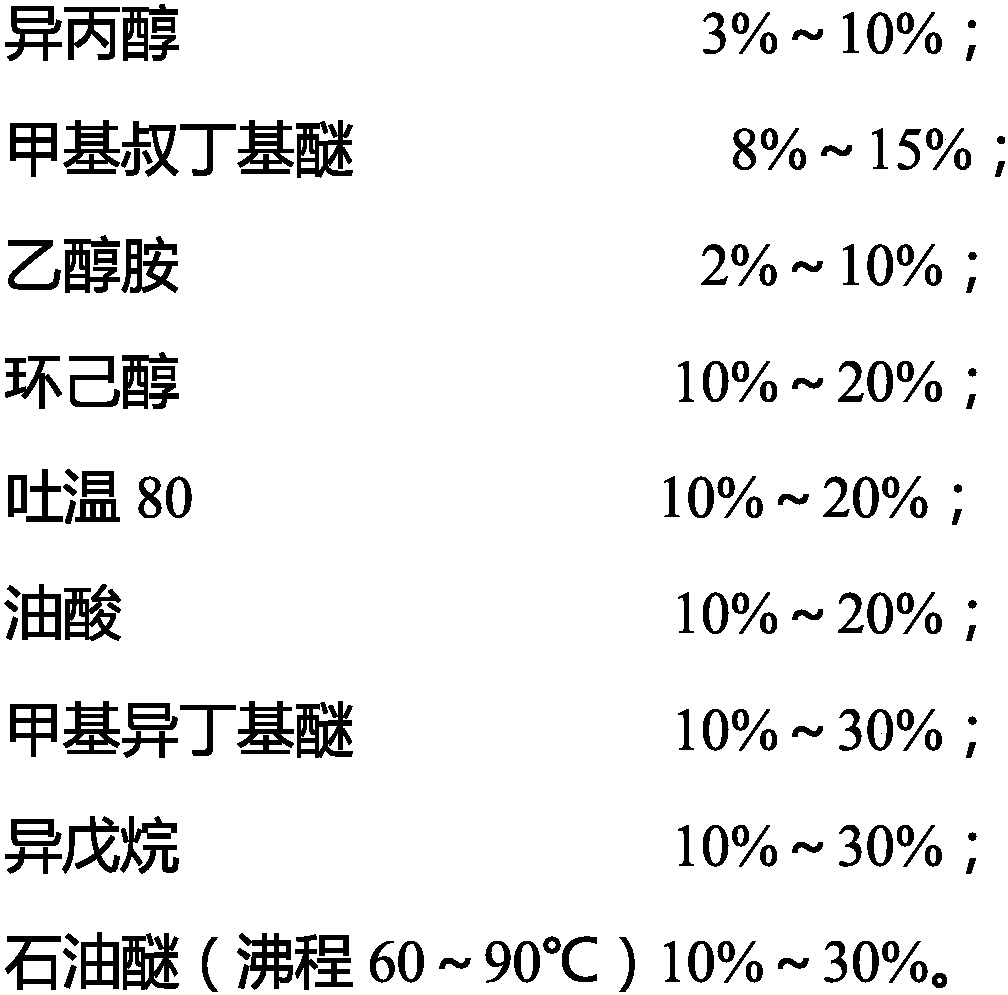

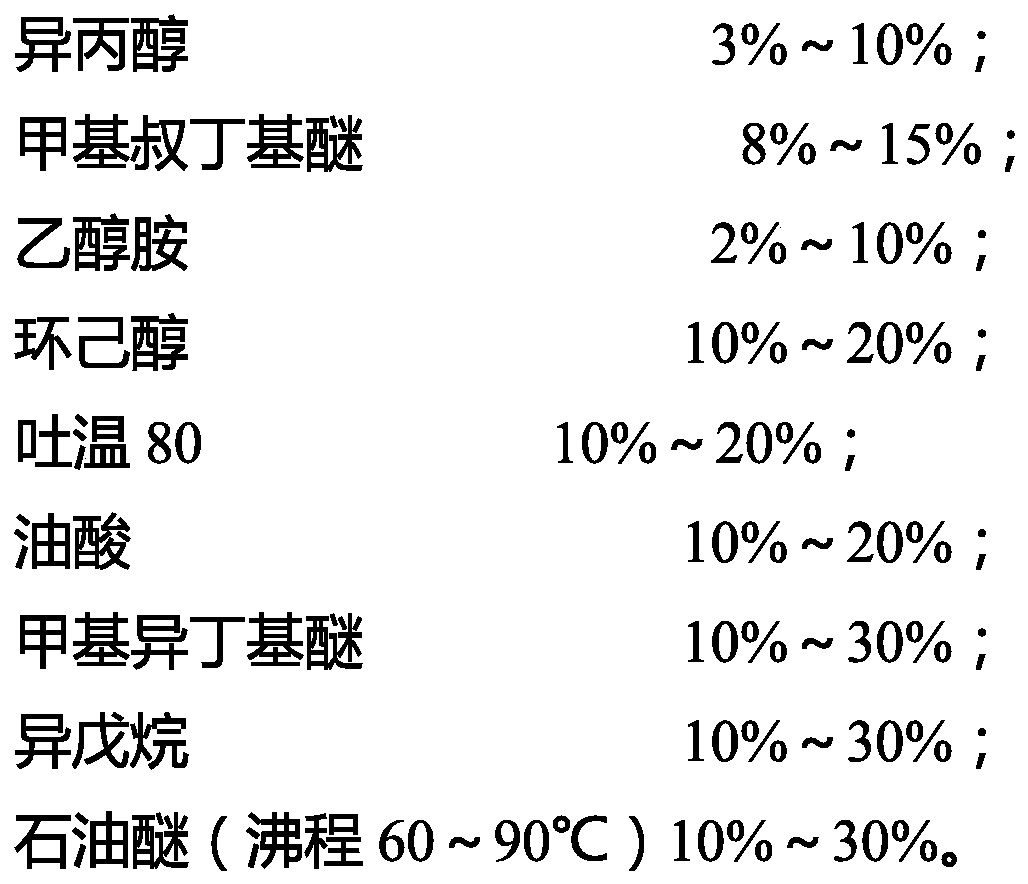

Method used

Image

Examples

Embodiment 1

[0025] Add 5g of isopropanol, 10g of methyl tert-butyl ether, and 4g of ethanolamine to a four-necked flask with mechanical stirring, a thermometer, an addition funnel, and a condenser in sequence, raise the temperature to 80°C and react for 2 hours, then cool down to room temperature to obtain Component A 19g.

[0026] Add 12g of cyclohexanol, 12g of Tween 80, and 12g of oleic acid into a four-necked flask, raise the temperature to reflux, and react for 1.5 hours to obtain 36g of component B.

[0027] Add 15g of methyl tert-butyl ether, 15g of isopentane, 15g of petroleum ether, the above-mentioned components A and B into the reaction flask, control the temperature at 15°C, and stir well to obtain 100 g of light yellow liquid of performance improver. The density at 20°C is 0.7994g / cm3.

[0028] Add 20.0 mL of the above performance improver to 980.0 mL of methanol (purity: 99.9%) to prepare 1000 mL of M100 methanol fuel for vehicles.

Embodiment 2

[0030] According to the component ratio of Example 1, the performance improver is industrially prepared. Take 2.0L of performance improver and 98.0L of methanol to make 100L M100 methanol fuel for vehicles, and carry out bench test.

[0031] The test is based on GB 18285-2005 "Limits and Measurement Methods of Exhaust Pollutants from Ignition Engine Vehicles (Double Idle Speed Method and Simple Working Condition Method)", GB / T 12547-2009 "Test Method for Minimum Stable Speed of Automobiles", GB / T T 12543-2009 "Automobile Acceleration Performance Test Method", GB / T 12544-2012 "Automobile Maximum Speed Test Method", GB / T12545.1-2008 "Passenger Car Fuel Consumption Test Method" and other standards, the test oil is National standard 95# gasoline and prepared M100 vehicle methanol fuel, the test results are as follows:

[0032] (1) In terms of power, the output torque of M100 methanol fuel is 0.32% lower than that of national standard 95# gasoline, and the output power of th...

Embodiment 3

[0036] Add 1.44kg of isopropanol, 2.88kg of methyl tert-butyl ether, and 1.15kg of ethanolamine to a 50L reactor in sequence, raise the temperature to 80°C and react for 2 hours, then cool down to room temperature to obtain product A.

[0037] Add 3.46kg of cyclohexanol, 3.46kg of Tween 80, and 3.46kg of oleic acid into the reactor, raise the temperature to reflux temperature and react for 1.5h to obtain product B.

[0038] Put, 4.32kg of methyl tert-butyl ether, 4.32kg of isopentane, 4.32kg of petroleum ether, and the product A and product B obtained above into the reaction kettle, control the reaction temperature at 10°C, stir well to obtain a light yellow performance improvement The liquid product is 28.81Kg, and the density at 20°C is 0.7994g / cm3.

[0039] Using 30L performance improver and 1470L methanol (purity 99.9%) to prepare 1500L M100 vehicle methanol fuel, the bench test results are as follows:

[0040] (1) In terms of power, the output torque of M100 methanol fue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com