Preparation method of nickel-cobalt-manganese ternary precursor material

A nickel-cobalt-manganese and precursor technology, applied in the field of lithium-ion battery preparation, can solve problems such as ball cracking, poor performance of positive electrode materials, uneven particles, etc., and achieve high economic practicability, controllable and easy-to-operate equipment and related conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

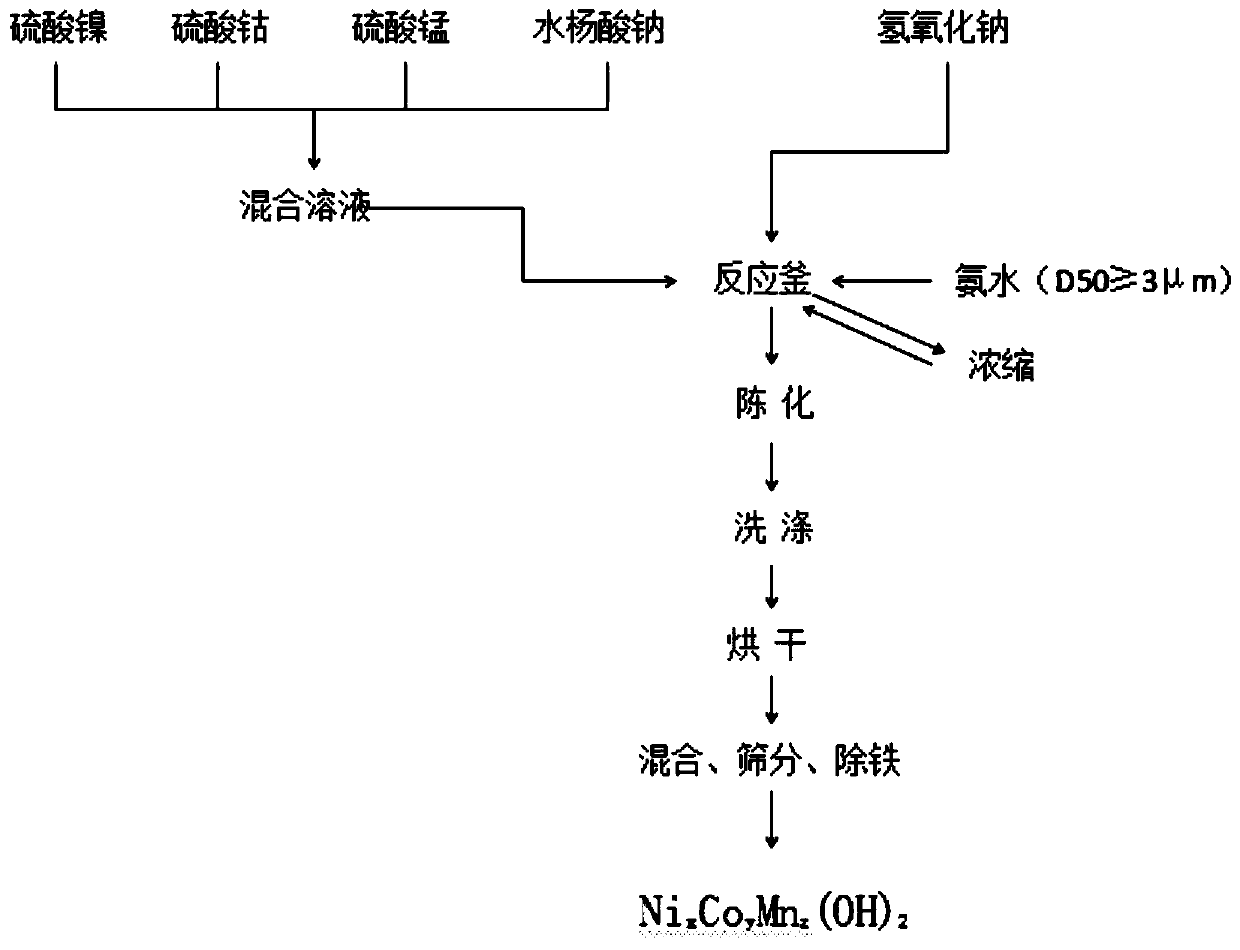

[0032] This embodiment provides a method for preparing a nickel-cobalt-manganese ternary precursor, comprising the following steps:

[0033] According to the ratio of 8:1:1, prepare NiSO with a concentration of 1.6mol / L 4 、CoSO 4 , MnSO 4 Mixed solution, and add sodium salicylate to prepare a mixed solution with a molar concentration of sodium salicylate of 0.05mol / L, use a metering pump to flow the mixed solution and 10mol / L lye into the reactor, the first stage, the reactor The stirring speed is 1000r / min, the pH is 11.60, and the temperature is 50°C; in the second stage, after the particle D50≥3μm is measured by Malvern 2000, 0.5mol / L ammonia water is introduced to control the ammonia value in the reactor at 6~ 7. The pH is 10.50. The two-stage process is concentrated with a concentrator to increase the solid content. The particle D50 ≥ 5 μm is measured by Malvern 2000 to stop the reaction; the slurry is aged, washed, dried, mixed, sieved, and removed After iron, the pre...

Embodiment 2

[0036] This embodiment provides a method for preparing a nickel-cobalt-manganese ternary precursor, comprising the following steps:

[0037] According to the ratio of 5:2:3, prepare NiSO with a concentration of 1.6mol / L 4 、CoSO 4 , MnSO 4 Mixed solution, and add sodium salicylate to prepare a mixed solution with a molar concentration of sodium salicylate of 0.05mol / L, use a metering pump to flow the mixed solution and 10mol / L lye into the reactor, the first stage, the reactor The stirring speed is 1100r / min, the pH is 11.60, and the temperature is 50°C; in the second stage, after the particle D50≥3μm is measured by Malvern 2000, 0.5mol / L ammonia water is introduced to control the ammonia value in the reactor at 6~ 7. The pH is 10.50. The two-stage process is concentrated with a concentrator to increase the solid content. The particle D50 ≥ 5 μm is measured by Malvern 2000 to stop the reaction; the slurry is aged, washed, dried, mixed, sieved, and removed After iron, the pre...

Embodiment 3

[0040] This embodiment provides a method for preparing a nickel-cobalt-manganese ternary precursor, comprising the following steps:

[0041] According to the ratio of 8:1:1, prepare NiSO with a concentration of 1.6mol / L 4 、CoSO 4 , MnSO 4 Mixed solution, and add sodium salicylate to prepare a mixed solution with a molar concentration of sodium salicylate of 0.1mol / L, use a metering pump to flow the mixed solution and 10mol / L lye into the reactor, the first stage, the reactor The stirring speed is 1000r / min, the pH is 11.60, and the temperature is 45°C; in the second stage, after the particle D50≥3μm is measured by Malvern 2000, 0.5mol / L ammonia water is introduced to control the ammonia value in the reactor at 6~ 7. The pH is 10.50. The two-stage process is concentrated with a concentrator to increase the solid content. The particle D50 ≥ 5 μm is measured by Malvern 2000 to stop the reaction; the slurry is aged, washed, dried, mixed, sieved, and removed After iron, the prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com