Semipermeable composite membrane and method for producing same

A composite semi-permeable membrane and manufacturing method technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc. High salt removal rate, the effect of realizing salt removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

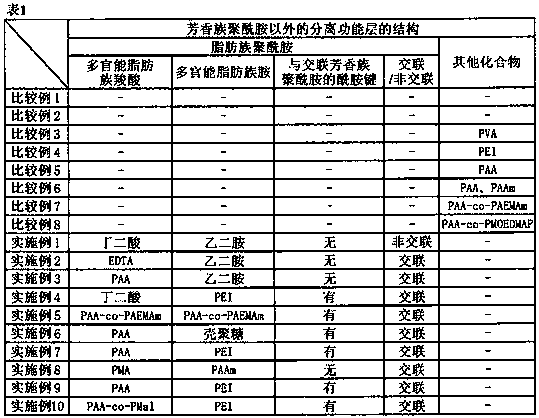

Examples

Embodiment

[0210] Hereinafter, although an Example is given and this invention is demonstrated, this invention is not limited at all by these Examples.

[0211] [1. Measurement of properties]

[0212] (NaCl removal rate)

[0213] To the composite semipermeable membrane, evaluation water with a temperature of 25°C, a pH of 7, and a sodium chloride concentration adjusted to 2,000 ppm was supplied at an operating pressure of 1.55 MPa, and membrane filtration treatment was performed. The electrical conductivity of the feed water and the permeated water were measured with a conductivity meter manufactured by Toa Denpa Kogyo Co., Ltd. to obtain the respective actual salt content, that is, the NaCl concentration. Based on the NaCl concentration thus obtained and the following formula, the NaCl removal rate was calculated.

[0214] NaCl removal rate (%)=100×{1-(NaCl concentration in permeate water / NaCl concentration in supply water)}

[0215] (through rate)

[0216] In the test of the preced...

Synthetic example 1

[0237] Adjust to form a pH 3 aqueous solution of 5% by weight of N-[3-(aminoethyl)]methacrylamide hydrochloride (AEMAm) and 5% by weight of acrylic acid (AA), and after bubbling with nitrogen, 3% by weight of sodium persulfate was added as an initiator, and a polymerization reaction was performed at 70° C. for 2 hours to obtain a polymer (PAA-co-PAEMAm) with a weight average molecular weight of 7,100.

Synthetic example 2

[0239] In addition to using 3-[[2-(methacryloyloxy)ethyl)]dimethylammonium] propionate (MOEDMAP) instead of AEMAm, according to Synthesis Example 1, a polymer with a weight average molecular weight of 12,000 was obtained substance (PAA-co-PMOEDMAP).

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com