Crystalline-state nanocellulose-based double circularly polarized light/fluorescent thin film material as well as preparation method and application thereof to anti-counterfeiting label

A nanocellulose, circularly polarized light technology, applied in the direction of polarizing elements, optics, optical elements, etc., to achieve the effect of simple processing method, low cost, and diversified patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

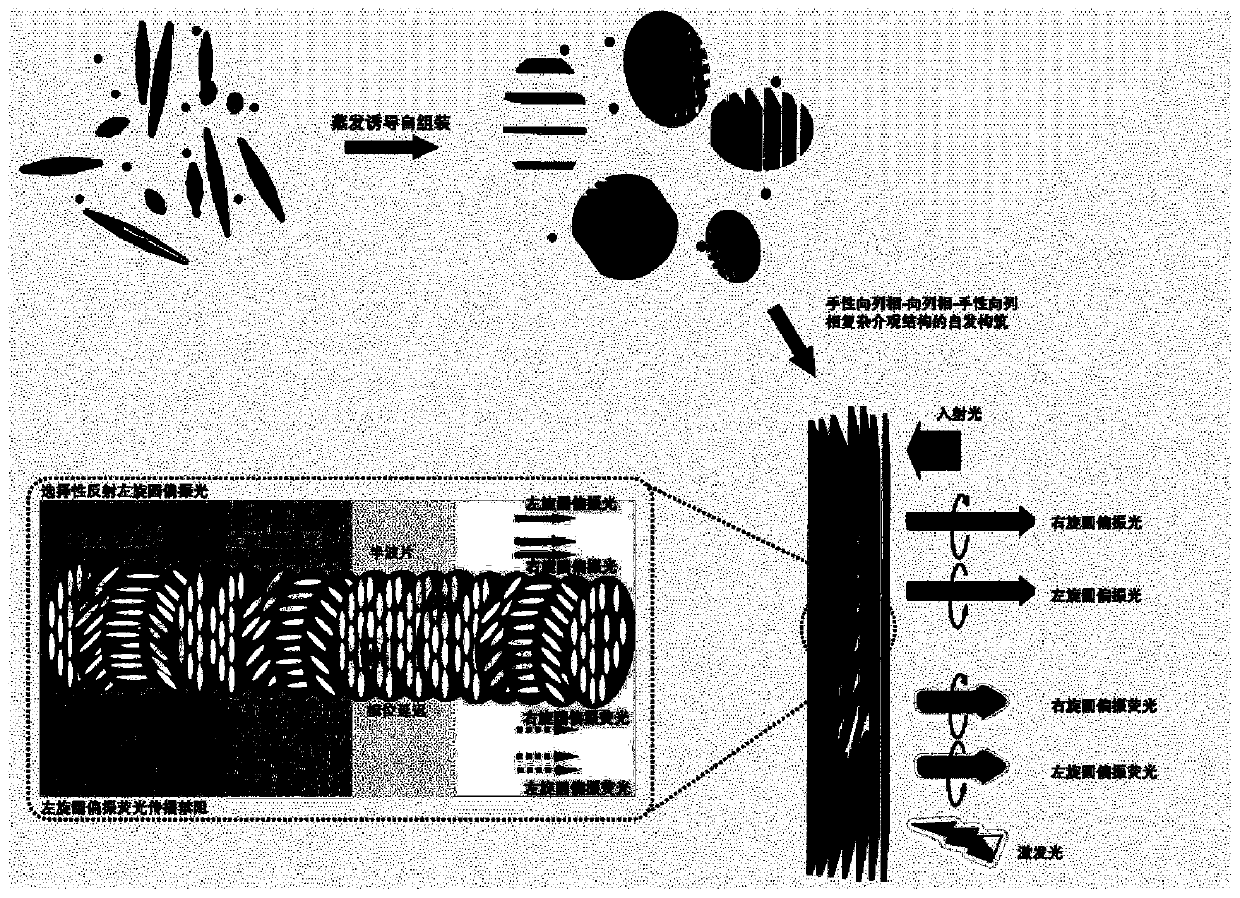

Problems solved by technology

Method used

Image

Examples

Embodiment 1

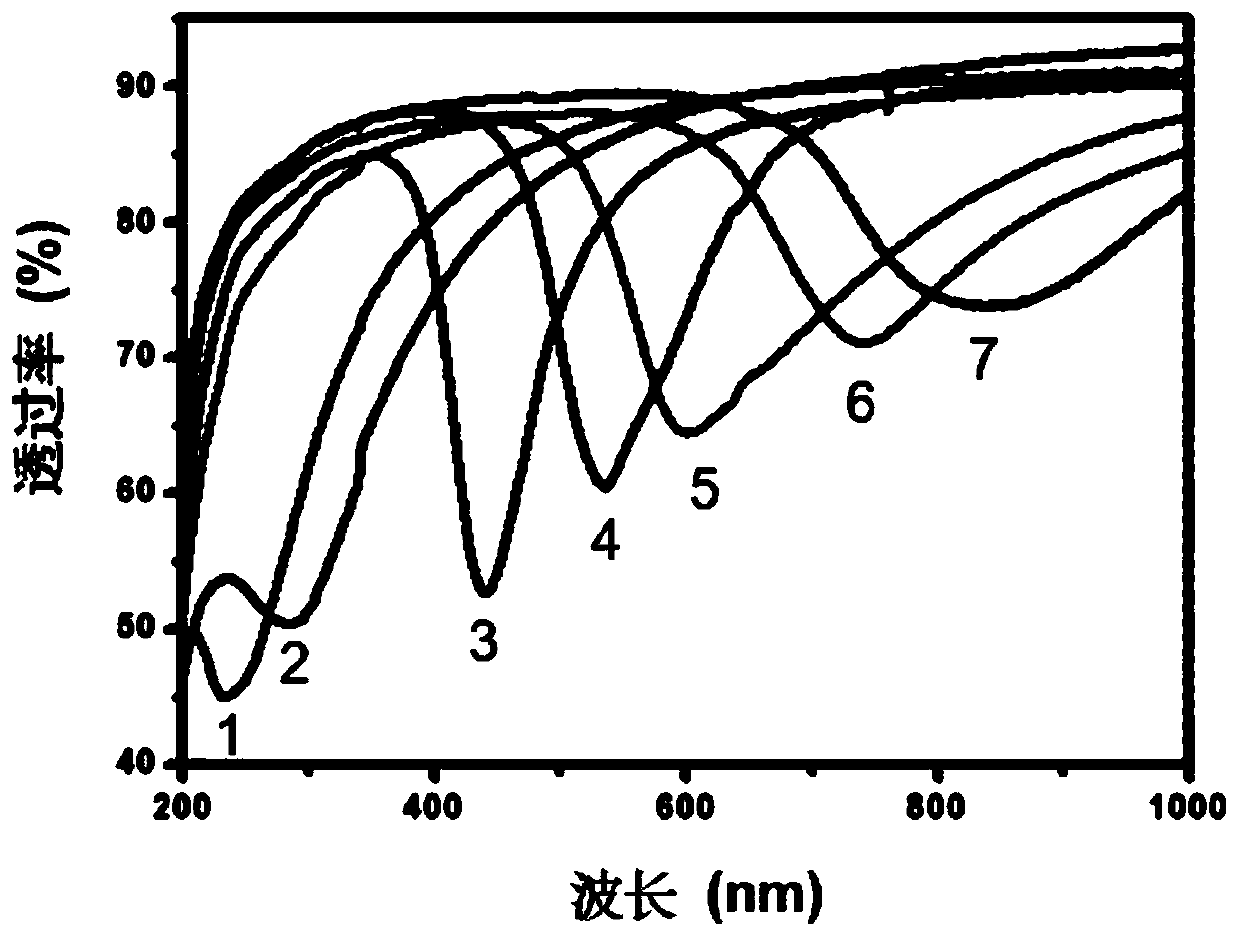

[0055] Example 1: Preparation of crystalline nanocellulose-based dual circularly polarized light / fluorescent film materials under the conditions of 4°C evaporation temperature and 4% initial concentration mass fraction of crystalline nanocellulose colloidal solution:

[0056] (1) Cellulose (cotton pulp cellulose 20g) was stirred with 64% sulfuric acid aqueous solution (220mL) at 45°C for 90min for hydrolysis reaction, then deionized water was used to terminate the reaction, and the obtained solution was poured out after standing The supernatant solution is centrifuged and washed 4 times with deionized water, and the solution is dialyzed to pH=7 with deionized water to obtain a crystalline nanocellulose colloidal solution for use, with a mass fraction of 1-2%.

[0057] (2) Concentrate the crystalline nanocellulose colloidal solution obtained in step (1) to a mass fraction of 4%, take 4 mL of the colloidal solution of the concentrated crystalline nanocellulose obtained, stir for ...

Embodiment 2

[0060] Example 2: Preparation of crystalline nanocellulose-based double circularly polarized light / fluorescence film material under the conditions of 25°C evaporation temperature and 4% initial concentration mass fraction of crystalline nanocellulose colloid:

[0061] (1) The operation is the same as in Embodiment 1.

[0062] (2) Concentrate the crystalline nanocellulose colloidal solution obtained in step (1) to a mass fraction of 4%, take 4 mL of the colloidal solution of the concentrated crystalline nanocellulose obtained, stir for 2 hours, and after forming a uniform and stable solution, pour Put it into a petri dish with a diameter of 3.5 cm, self-assemble at 25° C., and obtain a crystalline nanocellulose bi-circularly polarizing film 2 after the water evaporates.

[0063] Concentrate the colloidal solution of crystalline nanocellulose obtained in step (1) to a mass fraction of 4%, take 35 mL of the colloidal solution of the concentrated crystalline nanocellulose obtained...

Embodiment 3

[0066] Example 3: Preparation of crystalline nanocellulose-based dual circularly polarized light / fluorescent film materials under the conditions of 50°C evaporation temperature and 4% initial concentration of crystalline nanocellulose colloid mass fraction:

[0067] (1) The operation is the same as in Embodiment 1.

[0068] (2) Concentrate the crystalline nanocellulose colloidal solution obtained in step (1) to a mass fraction of 4%, take 4 mL of the colloidal solution of the concentrated crystalline nanocellulose obtained, stir for 2 hours, and after forming a uniform and stable solution, pour Put it into a petri dish with a diameter of 3.5 cm, self-assemble at 50°C, and obtain a crystalline nanocellulose bicircularly polarizing film 3 after the water evaporates.

[0069] Concentrate the colloidal solution of crystalline nanocellulose obtained in step (1) to a mass fraction of 4%, take 4 mL of the colloidal solution of the concentrated crystalline nanocellulose obtained, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com