Microtube sensor for physiological monitoring

A technology of sensors and microtubes, which is applied in the direction of micro sensors, sensors, and the measurement of the properties and forces of piezoresistive materials, etc., which can solve the problem of limiting the design and integration of operating elements, limiting scalability and reproducibility, complex production processes, etc. problem, achieve sensitive force measurement, increase wearability, and reduce electronic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

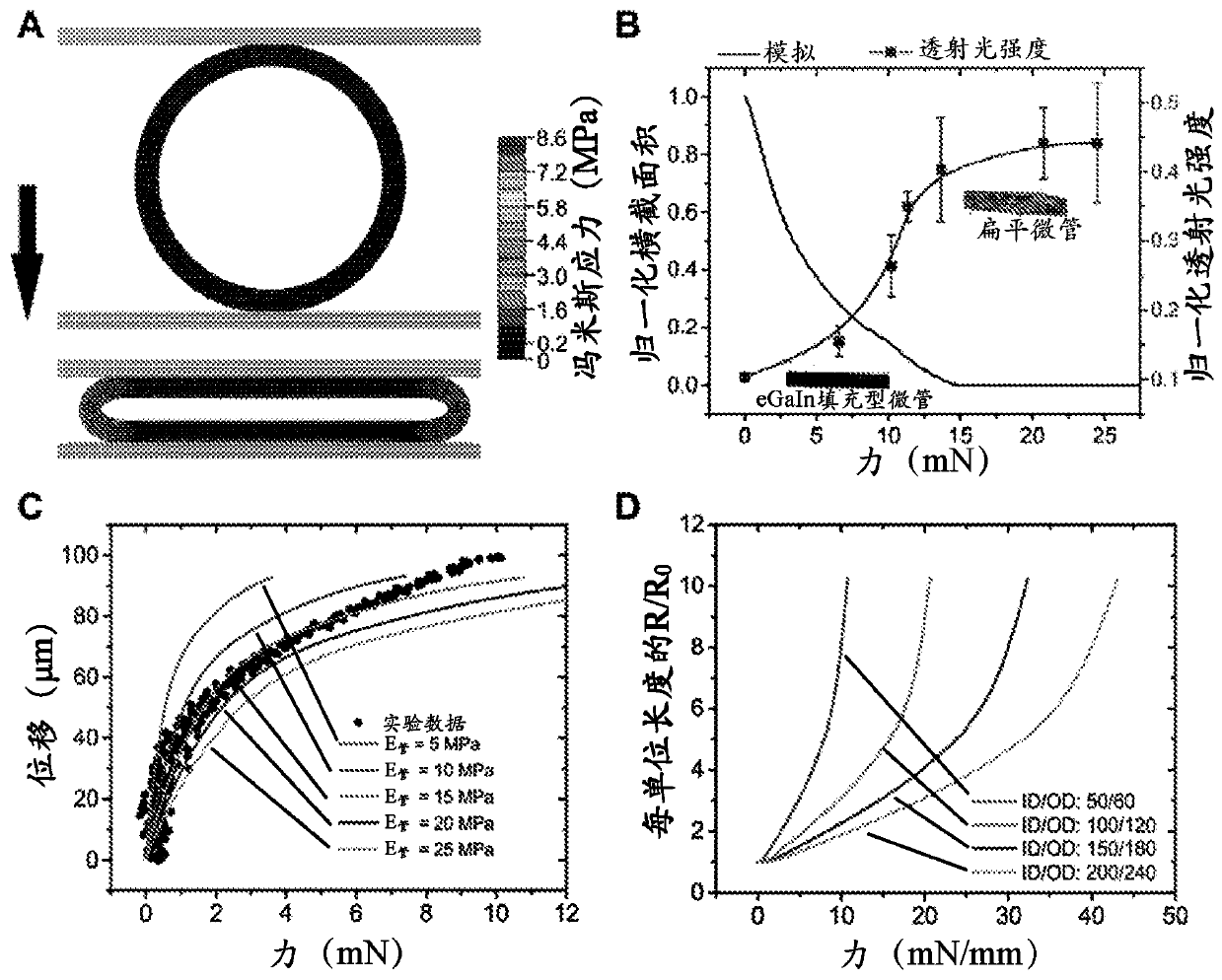

[0098] Example 1 - Finite Element Analysis:

[0099] Finite element modeling of the microtubule tactile sensor was performed using ABAQUS CAE for 2D plane strain and 3D analysis, depending on the geometry of the top tooth pitch (ie, the crosshead that compresses the microtubule). Due to the symmetry, one-half and one-quarter models were built for 2D plane strain and 3D analysis, respectively. Select the general static analysis mode, in which a hard and frictionless contact is established between the top tooth pitch and the outer surface of the upper half of the microtubule, the bottom plate and outer surface of the lower half of the microtubule, and the inner surface of the microtubule. Use mixed and linear elements with reduced order integration for contact analysis. The pipe wall is divided into 6 layers in the region of high stress near the mid-plane and into 4 layers in other regions. Assuming that flexible polydimethylsiloxane (PDMS) is elastic, [10] And Poisson's rati...

example 2

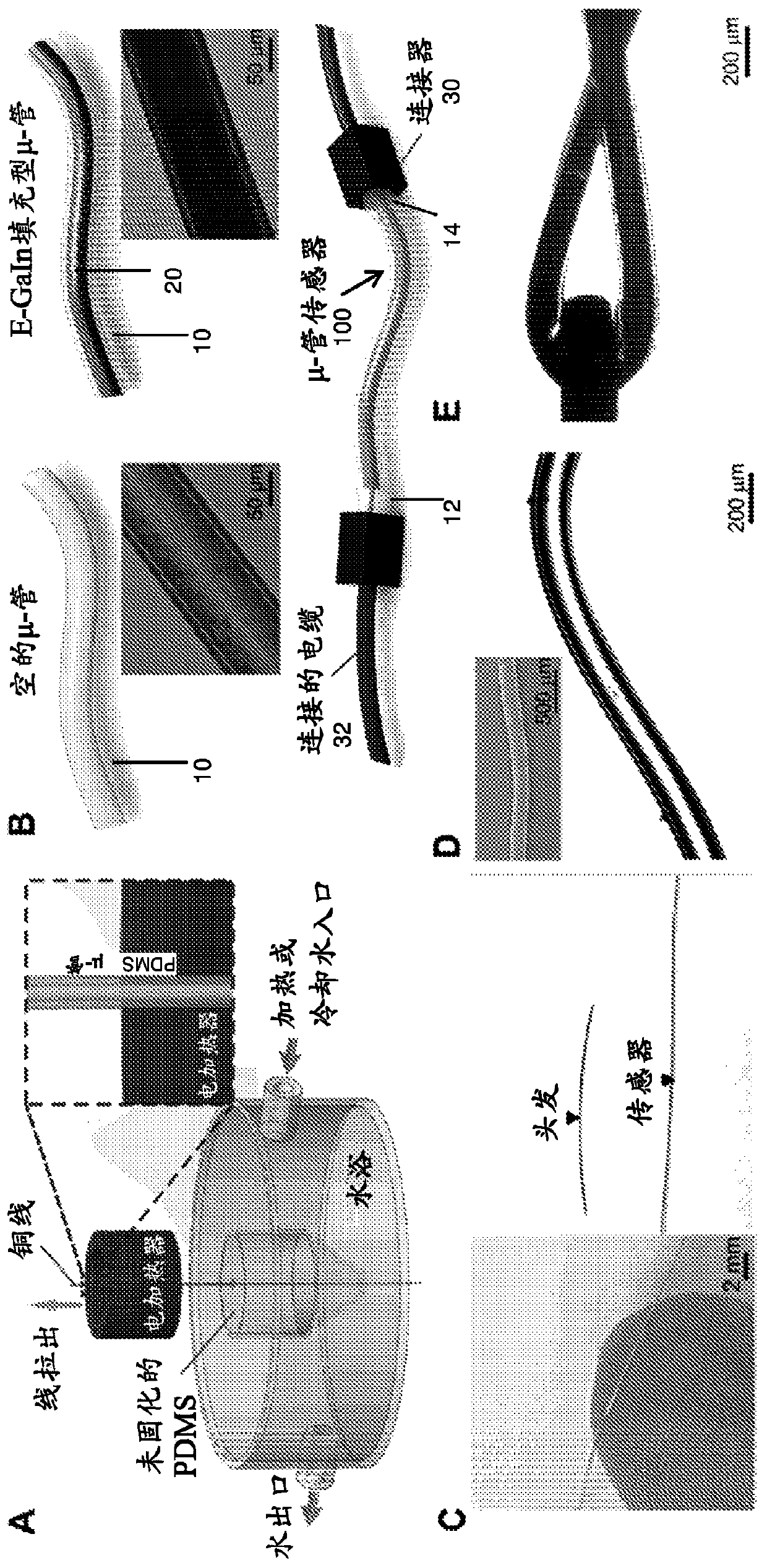

[0100] Example 2 - Device Design and Fabrication:

[0101] To fabricate microtubes, first dip a wire (e.g., wire) vertically into a 10:1 (w / w) mix of freshly mixed PDMS base and curing agent (e.g., 10:1 by weight of Sylgard 184 Silicon resin elastomer base and Sylgard 184 silicone elastomer curing agent). Pull the wire from the PDMS cell using a rotary motor at a speed of 2 mm / s to 4 mm / s. Simultaneously, hot water at ~100 °C was added to the surrounding PDMS pool to initiate PDMS curing. Solidification was further performed by hot air at ~95°C in a cylindrical heating device while the wire was drawn vertically above the liquid level. To maintain the optimum viscosity of PDMS for uniform coating around the wire, cold water can be added around the PDMS pool to prolong the curing time. Next, the metal wires were stripped during a sonication process in acetone solution, which washed away the unreacted elastomer curing agent and caused a slight swelling of the polymer, thereby ...

example 3

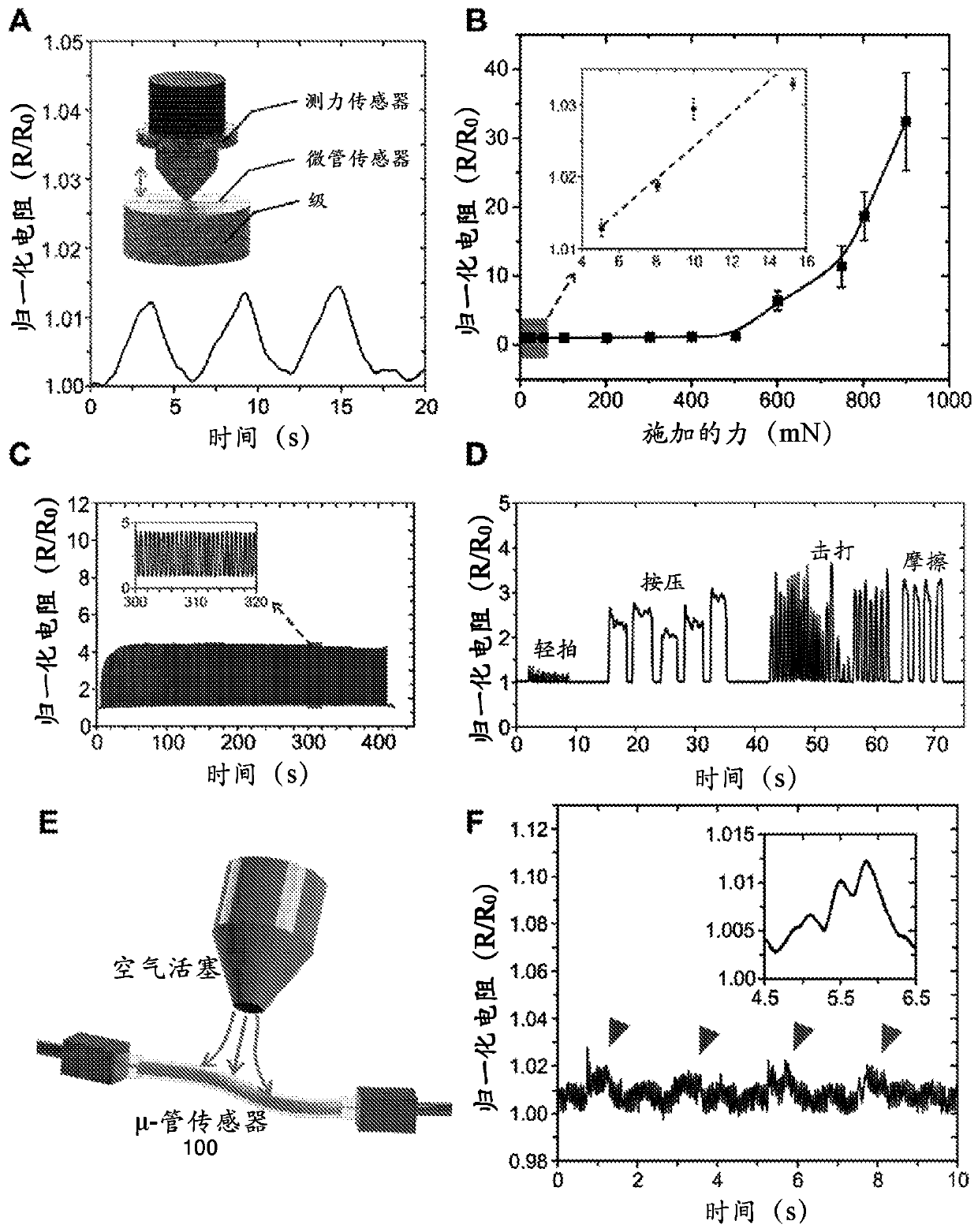

[0102] Example 3 - Pressure Sensing, Durability and Mechanical Differentiation:

[0103] A universal load machine (5848 MicroTester from Instron, Norwood, MA) was used to subject the liquid-based microtube tactile sensor to a compression ramp-hold-release load of 10 mN to 100 mN, as in Figure 3A Shown schematically. The ramp and release rate were set at 5 mm / min. The electrical response of the tactile sensor under different load applications was continuously monitored and recorded at 20 Hz using a custom data logging microprocessor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com