A kind of modified graphene oxide ultraviolet photocatalytic film and preparation method thereof

A technology of catalytic film and ultraviolet light, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of small light contact area and poor photocatalytic performance, and achieve simple steps and rigorous operation , good effect of ultraviolet photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

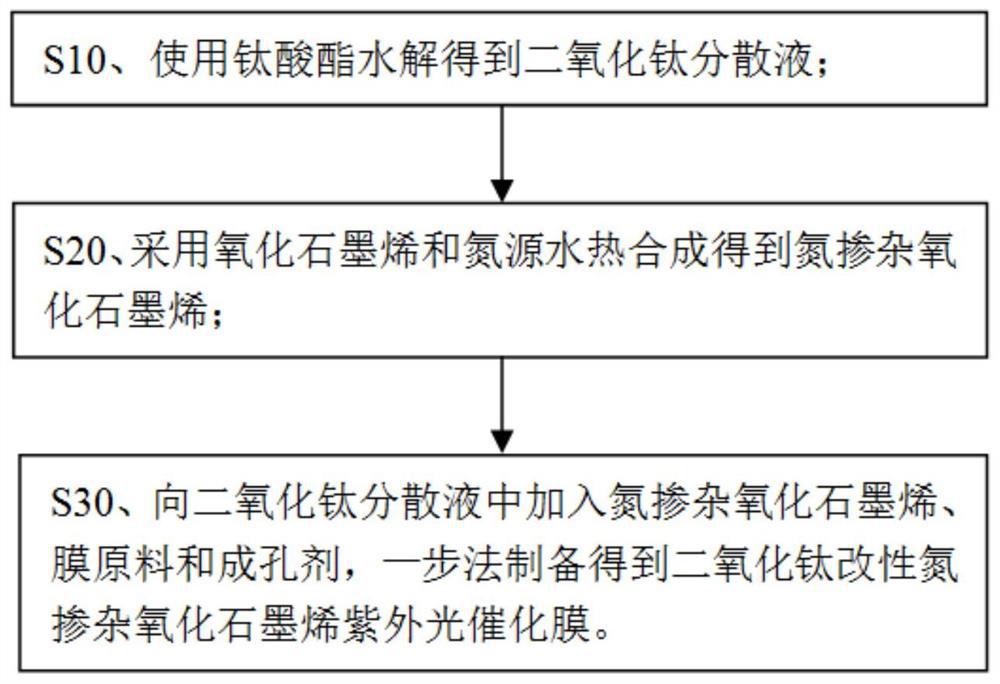

[0040] like figure 1 As shown, the preparation method of a modified graphene oxide ultraviolet photocatalytic film of the present invention, the specific steps are:

[0041] S10, using titanate hydrolysis to obtain titanium dioxide dispersion, the specific process is:

[0042] (1) pour 6ml tetrabutyl titanate into 20ml dehydrated alcohol to obtain tetrabutyl titanate dehydrated alcohol solution;

[0043] (2) Add a 0.08M nitric acid solution with a volume of V1 to the tetrabutyl titanate anhydrous ethanol solution, stir under non-sealed conditions at 20-25°C, the stirring speed is 250r / min, and the stirring time is After stirring for 10 min, a reaction solution was obtained;

[0044] (3) the reaction solution is heated to 65~75 ℃ (70 ℃ in this embodiment), stir to carry out hydrolysis reaction, the speed of stirring is 200r / min, and the stirring time is 45min, and then adding volume to the reaction solution is V2 The 0.08M nitric acid solution was stirred under airtight cond...

Embodiment 2

[0064] The content of this embodiment is basically the same as that of the embodiment, the difference is: the preparation method of a modified graphene oxide ultraviolet photocatalytic film of this embodiment, the specific steps are:

[0065] S10, using titanate hydrolysis to obtain titanium dioxide dispersion, the specific process is:

[0066] (1) pour 6ml tetrabutyl titanate into 20ml dehydrated alcohol to obtain tetrabutyl titanate dehydrated alcohol solution;

[0067] (2) Add 0.08M nitric acid solution with volume V1=30ml to the tetrabutyl titanate anhydrous ethanol solution, stir at 20-25°C under non-sealed conditions, the stirring speed is 250r / min, and the stirring time For 10min, the reaction solution was obtained after stirring;

[0068] (3) the reaction solution is heated to 70 ℃, and the hydrolysis reaction is carried out with stirring, and the stirring speed is 180r / min, and the stirring time is 45min, and then adding the 0.08M nitric acid solution whose volume is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com