Wax and paper separation process for waste wax cartons and application of wax and paper separation process

A carton and craft technology, which is applied in the field of wax and paper separation technology, can solve the problems of complicated separation technology, achieve the effect of increasing shear force and facilitating disintegration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

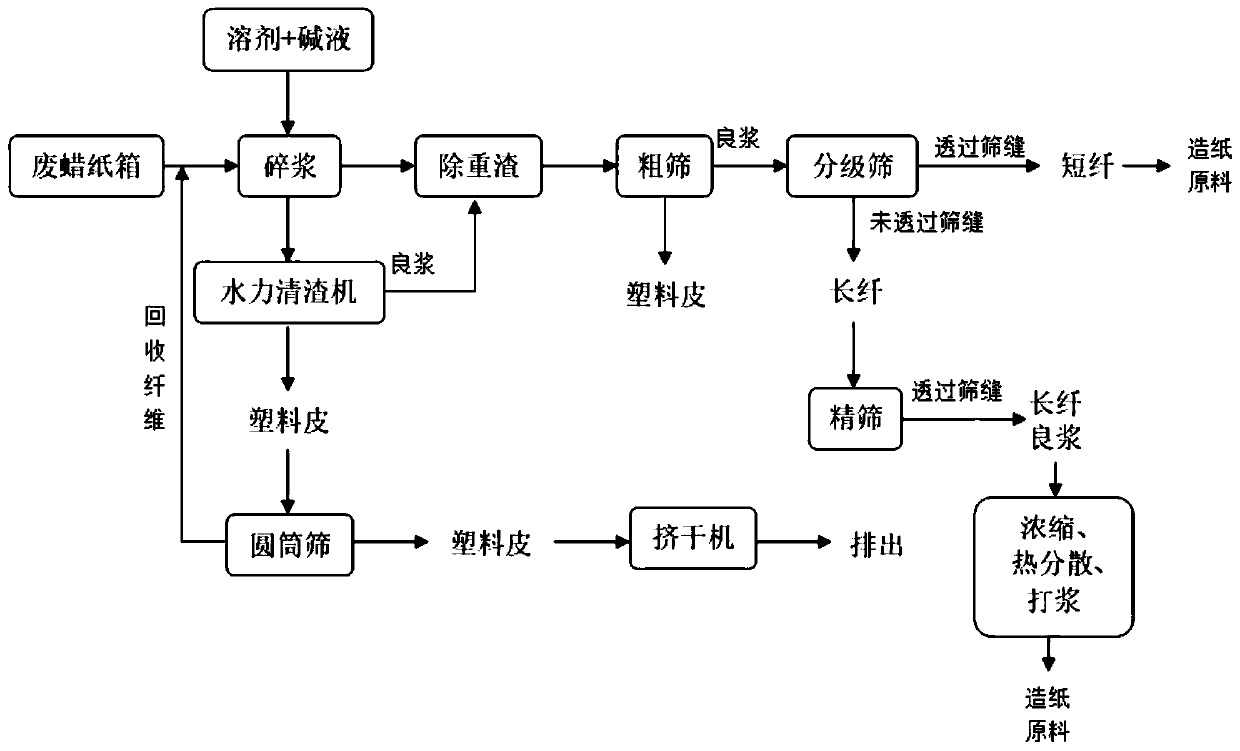

[0043] A kind of wax and paper separation process of waste wax carton of the present embodiment, combine figure 1 As shown, the waxed paper is transported from the chain plate machine to the hydropulper, adding pulping white water (water temperature 50°C), controlling the concentration of the waxed paper to 10%, and adding caustic soda, wherein the absolute dry dosage of caustic soda is 7kg of caustic soda per ton of waxed paper , maintain the hydropulper level at 50%, start the hydropulper, and stir the wax paper. After stirring for 30 minutes, continue to add white water for pulping, control the wax paper concentration to 6%, stir the wax paper for 30 minutes, and repeat 3 to 5 times. Open the discharge valve of the hydraulic pulper and discharge the pulp.

[0044] The slurry obtained from the hydraulic pulper is sent to the hydraulic slag cleaner for further disintegration, and the good pulp is reused. The slurry is then passed through a cylindrical sieve to remove the pla...

Embodiment 2

[0057] A wax and paper separation process for waste wax cartons in this embodiment, the wax paper is transported from the chain conveyor to the hydropulper, water (water temperature 45°C) is added to control the wax paper concentration to 12%, and KOH is added, wherein KOH The absolute dry dosage is to add 5kg of caustic soda per ton of wax paper, keep the liquid level of the hydropulper at 40%, start the hydropulper, and stir the wax paper. After stirring for 20 minutes, continue to add water, control the wax paper concentration to 7%, stir the wax paper for 20 minutes, repeat 3-5 times. Open the discharge valve of the hydraulic pulper and discharge the pulp.

[0058] The slurry obtained from the hydraulic pulper is sent to the hydraulic slag cleaner for further disintegration, and the good pulp is reused. The slurry is then passed through a cylindrical sieve to remove the plastic skin, and the fibers mixed in the plastic skin are obtained, and then the pulp is processed and ...

Embodiment 3

[0071] A wax and paper separation process for waste wax cartons in this embodiment, the wax paper is transported from the chain conveyor to the hydraulic pulper, adding pulping white water (water temperature 55°C), controlling the wax paper concentration to 8%, and adding caustic soda, Wherein the dry consumption of caustic soda is to add 10kg of caustic soda per ton of wax paper, the liquid level of the hydropulper is kept at 60%, start the hydropulper, and stir the wax paper. After stirring for 40 minutes, continue to add white water for pulping, control the wax paper concentration to 5%, stir the wax paper for 40 minutes, and repeat 3 to 5 times. Open the discharge valve of the hydraulic pulper and discharge the pulp.

[0072] The slurry obtained from the hydraulic pulper is sent to the hydraulic slag cleaner for further disintegration, and the good pulp is reused. The slurry is then passed through a cylindrical sieve to remove the plastic skin, and the fibers mixed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com