A kind of optical fiber magnetic field sensor and preparation method thereof

A magnetic field sensor and optical fiber technology, applied in the direction of the size/direction of the magnetic field, using magneto-optical equipment for magnetic field measurement, instruments, etc., can solve the problems of insufficient sensitivity of the fiber grating magnetic field sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

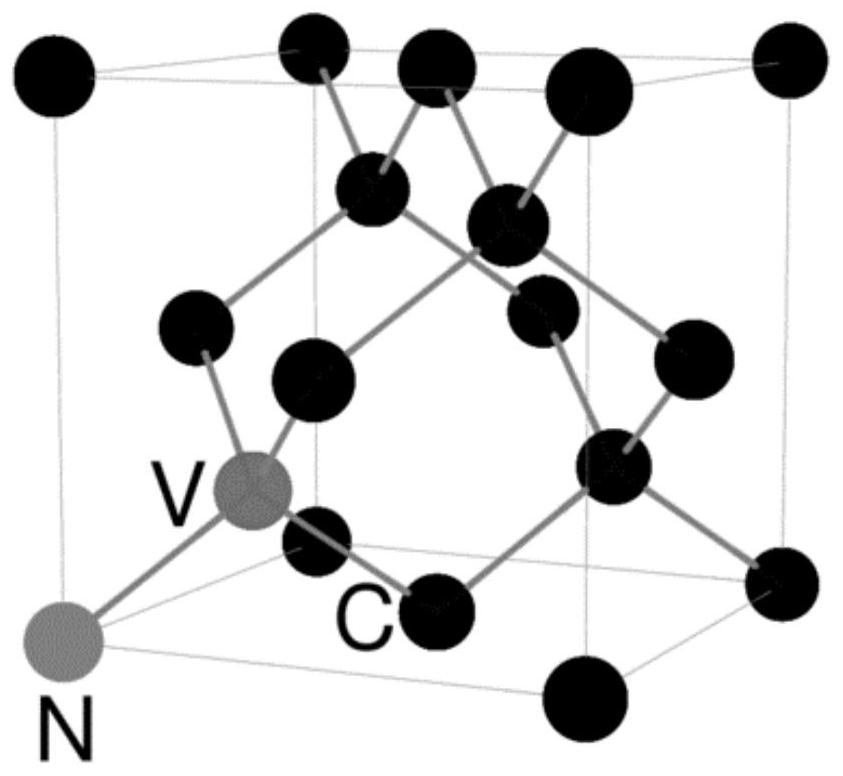

[0042] The preparation process of micro-nano-diamond particles is very mature. By detonating block diamond samples containing nitrogen-vacancy centers, micro-nano-scale diamond particles or micro-columns can be obtained, and nano-diamond particles without nitrogen-vacancy centers can also be obtained. The sample is ion-implanted to form nitrogen-vacancy centers.

[0043] The optical fiber can be a single-mode optical fiber or a multi-mode optical fiber. The diameter of the single-mode optical fiber is generally about 10 microns, and the diameter of the multi-mode optical fiber is 50 microns-100 microns. Single-mode fiber is recommended.

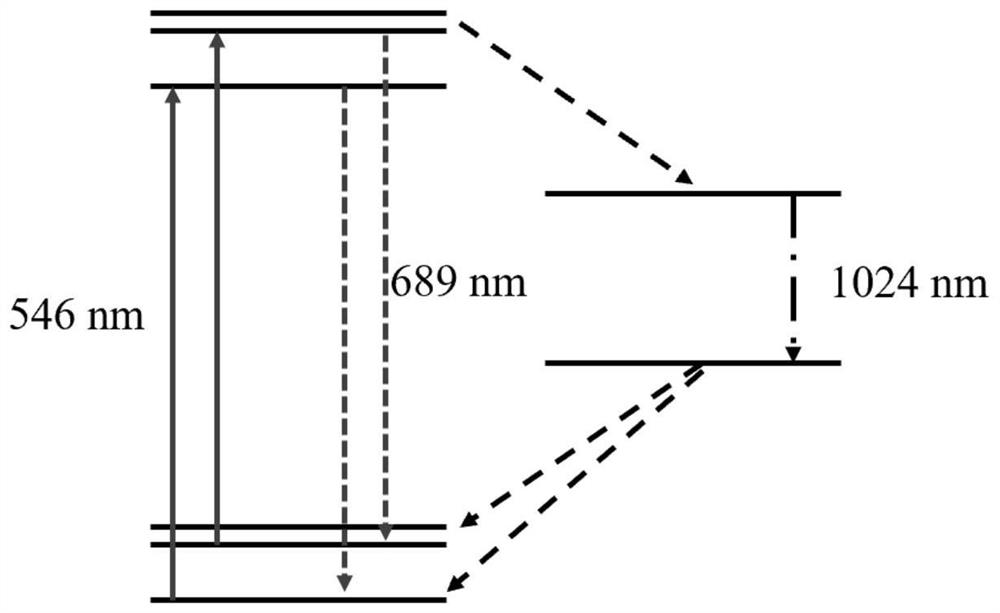

[0044] Implant and fix diamond micropillars or micro-nano diamond particles from one end of the optical fiber, and apply microwaves at the detection end, and then irradiate a laser with a specific wavelength (usually 532nm) from the other end, and collect nitrogen- Fluorescence emitted by the vacancy center can then be measured.

[0045] In...

Embodiment 1

[0048] Diamond microcolumns with a height of 10 microns and a diameter of 4 microns are prepared into an aqueous solution. The concentration of the aqueous solution can be adjusted according to needs. In order to ensure the preparation efficiency, the concentration can be configured to contain an average of 0.01 to 10 diamond microcolumns per cubic micron. The average diameter and length of the diamond microcolumn need to be less than the diameter of the fiber core used. In this embodiment, a single-mode fiber with a core diameter of 8 microns is selected, and one end of the fiber is immersed in the configured microcolumn solution, and the instrument is used from the other end. Or the device pumps out 0.1μL-1μL of gas, and the solution will be sucked into the optical fiber. Take the optical fiber out of the solution and dry it.

[0049] From the other end of the fiber, the 532nm laser light emitted by the laser is coupled into the fiber through the objective lens, and the fluo...

Embodiment 2

[0054] Place diamond microcolumn powder with a height of 10 microns and a diameter of 4 microns in a beaker, place one end of a single-mode optical fiber with a core diameter of 8 microns close to the surface of the powder, and use instruments or equipment to pump out 0.1 μL-1 μL of gas from the other end.

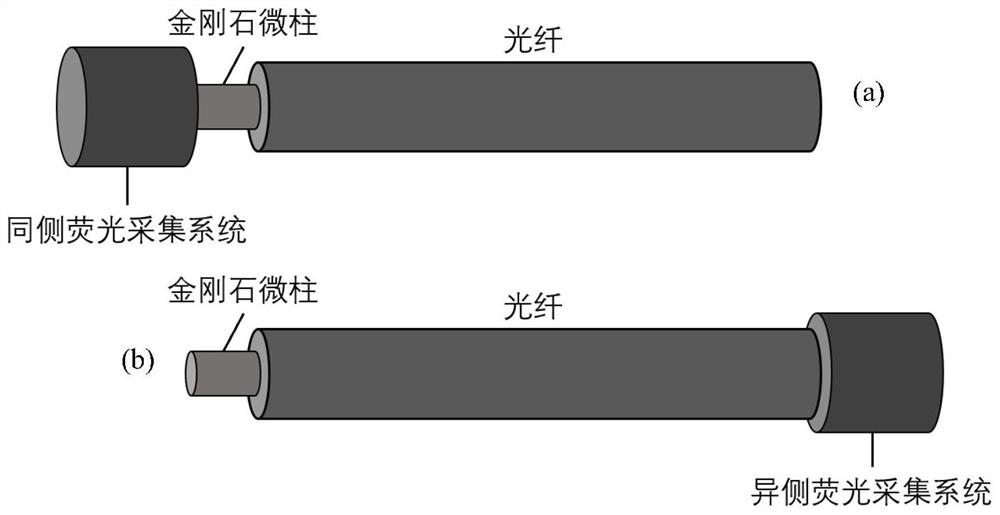

[0055] Implantation detection: refer to Figure 5 or Image 6 , Figure 5 Schematic diagram of the coupling diamond microcolumn or micro-nano diamond particles and optical fiber structure provided by the present invention, and realizing magnetic field measurement through microwave wires; Image 6 In order to couple the structure of diamond micropillars or micro-nano diamond particles and the optical fiber whose surface is etched with microwave wires, the microwave wires on the surface of the optical fiber are used to realize the magnetic field measurement, and the microwave waveguide can be implanted in the coating layer of the optical fiber to apply microwaves to the opt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com