Core-shell-structured hierarchical iron/copper bimetallic Fenton catalyst and preparation method and application thereof

A technology of iron catalyst and copper catalyst, applied in the direction of physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, chemical instrument and method, etc., can solve the problem of poor long-term stability of catalyst, easy leakage of Fe ions, catalyst Reduced catalytic efficiency and other issues, to achieve excellent catalytic performance, good reusability, stable catalyst effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

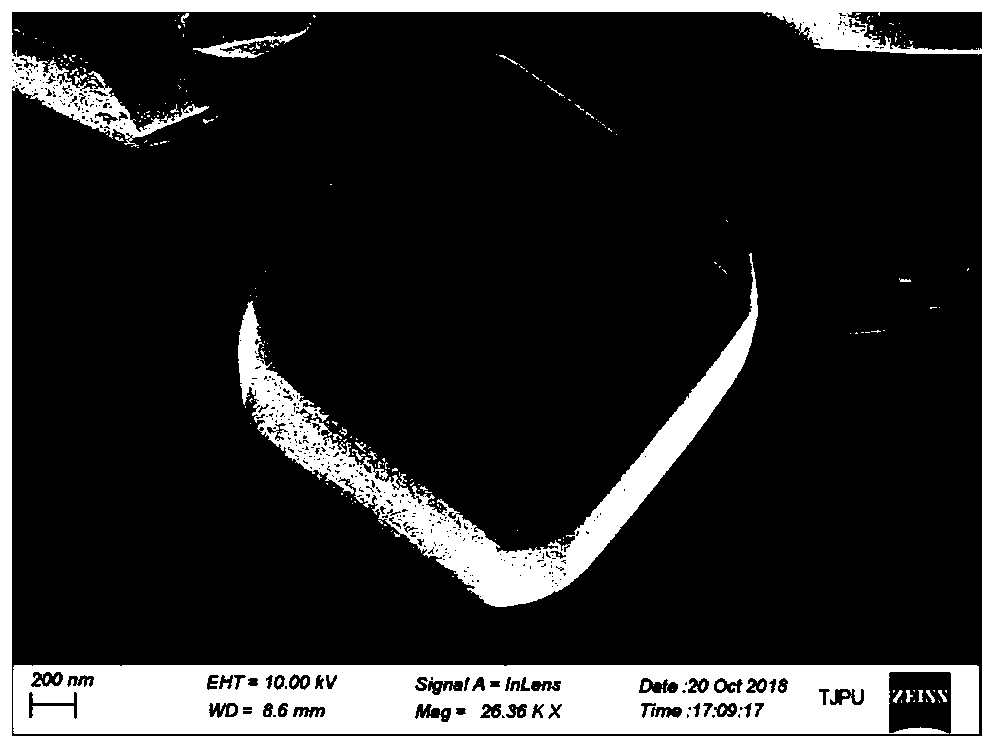

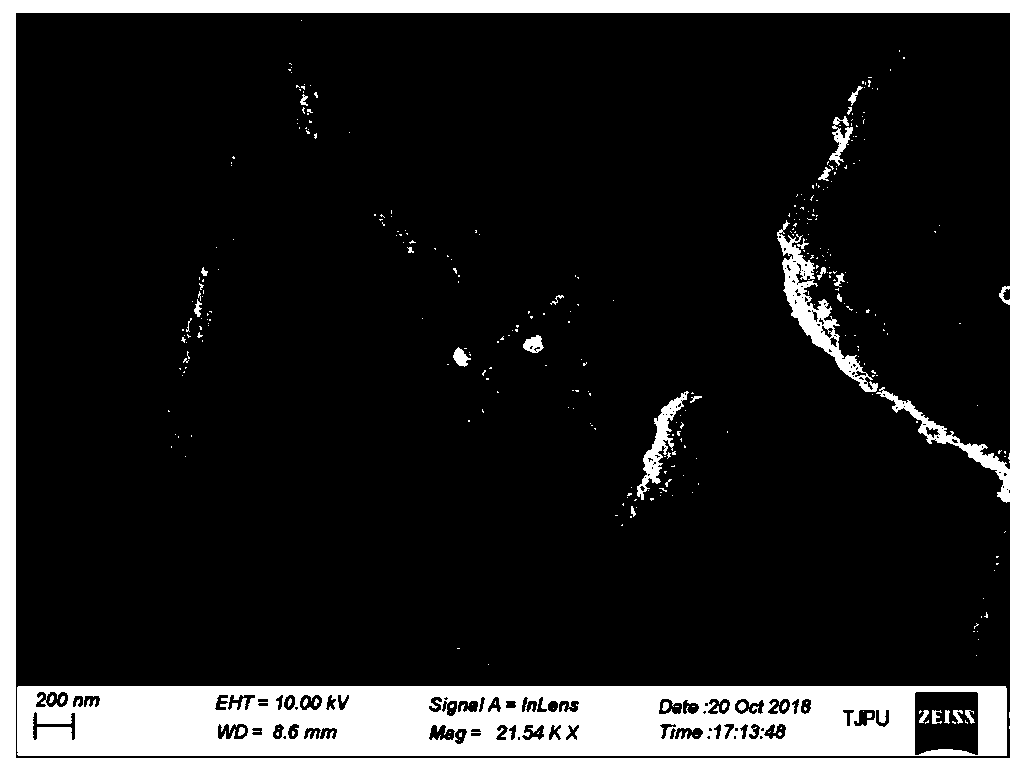

[0030] The embodiment of the present invention also provides a preparation method of the above-mentioned core-shell hierarchical iron / copper bimetallic Fenton catalyst, comprising the following steps,

[0031] 1) Preparation of the isolated iron catalyst: adding the zeolite to the ferric salt solution, stirring and reacting, centrifuging and washing with deionized water, and freeze-drying to obtain the isolated iron catalyst;

[0032] 2) Preparation of the core-shell graded iron / copper bimetallic catalyst: add the isolated iron catalyst obtained in step 1) into the divalent copper salt solution and stir for a certain period of time, then centrifugally wash with deionized water, freeze-dry to obtain the core Shell graded iron / copper bimetallic Fenton catalysts.

[0033] The method provided in this example uses zeolite as a raw material, and sequentially prepares a core-shell graded iron / copper bimetallic Fenton catalyst by "reacting with ferric salt solution—freeze drying—reactin...

Embodiment 1

[0048] Prepare 500mL of 2000mg / L ferric chloride solution with pH=1.6, then add 10g of 4A type zeolite into it, stir and react for 4h, centrifuge and wash with deionized water, then freeze-dry at -10℃~-80℃ to obtain isolated iron catalyst.

[0049] Prepare 500 mL of copper chloride solution with a copper ion concentration of 2000 mg / L pH=1.6, add 10 g of the prepared isolated iron catalyst to it, stir for 5 h, wash with centrifuge, and then freeze-dry at -10°C to -80°C to obtain Core-shell hierarchical iron / copper bimetallic Fenton catalysts.

[0050] The obtained core-shell graded iron / copper bimetallic Fenton catalyst is added to the phenol solution, and the catalytic reaction is carried out at normal temperature and pH=2 conditions, wherein the molar ratio of hydrogen peroxide and phenol is 14:1, the mass of catalyst and phenol The ratio is 5:1.

Embodiment 2

[0052] The preparation method of core-shell graded iron / copper bimetallic Fenton catalyst is the same as in Example 1

[0053] The method for degrading phenol with the core-shell hierarchical iron / copper bimetallic Fenton catalyst is the same as in Example 1, except that the pH of the solution is 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com