Online activation method of catalytic oxidation VOCs catalyst

A catalytic oxidation and activation method technology, applied in catalyst regeneration/reactivation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of high price, shortened catalyst service life and heavy operation burden and other problems, to achieve the effect of reducing operating costs, reducing catalyst consumption, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

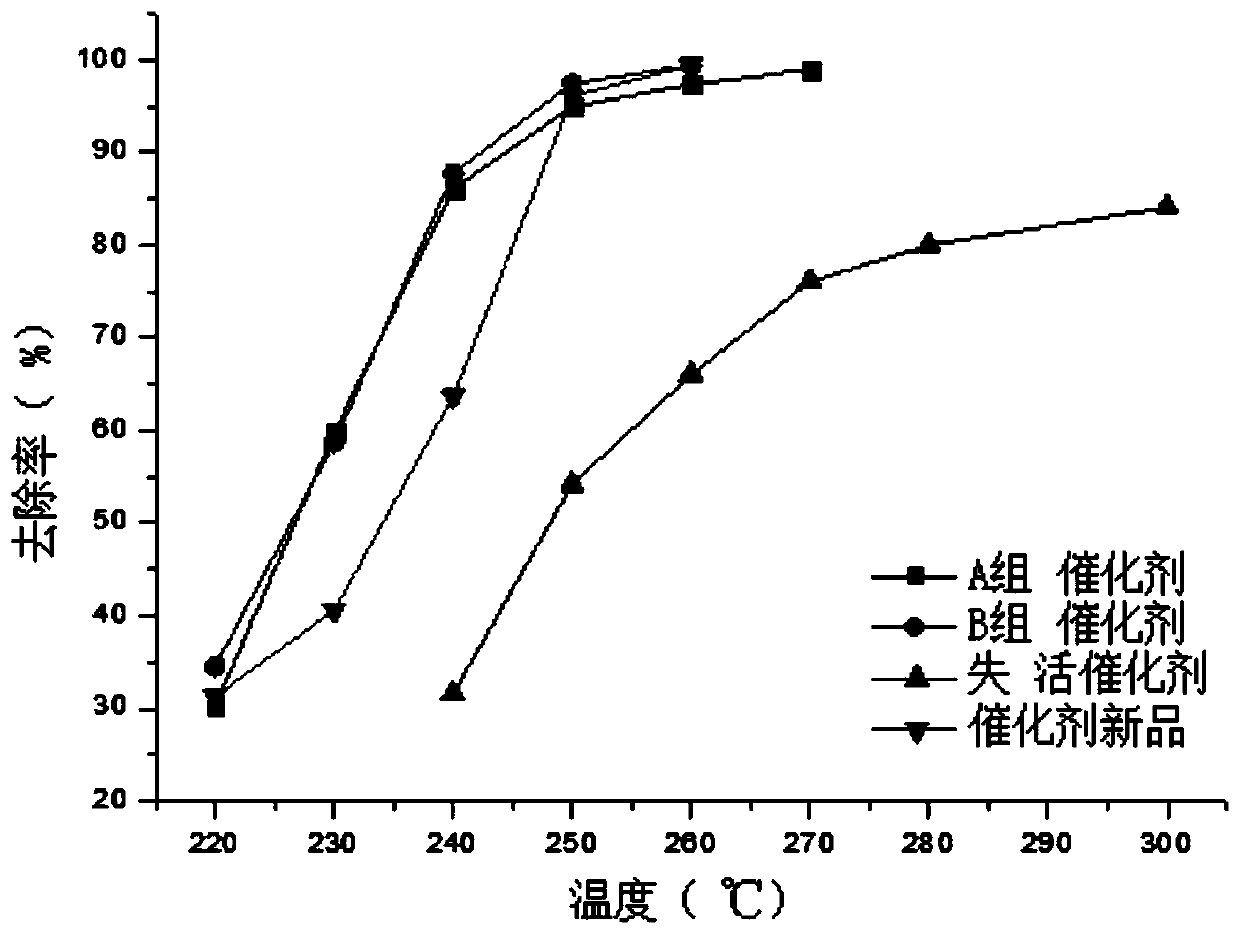

[0042] A and B groups of deactivated catalyst samples are all from the VOCs exhaust gas catalytic oxidation treatment equipment in operation in a certain factory. Due to improper on-site operation, the catalyst was deactivated by moisture. The distribution ratio of active components of group A catalyst is silver: manganese: cerium = 1:3:4, the distribution ratio of active components of group B catalyst is silver: manganese: cerium = 0.25:1.5:2, wherein the total ratio of active components of group B Group A is low. Use the activation replenishment solution A potion with the same distribution ratio of the active components of the catalyst in group A (the distribution ratio of the active components is silver: manganese: cerium = 1:3:4) to activate the deactivated catalysts of the two groups A and B online. It can be seen that group A belongs to moderate amount of active ingredient supplementation, and group B belongs to excessive amount of active ingredient supplementation. Spr...

Embodiment 2

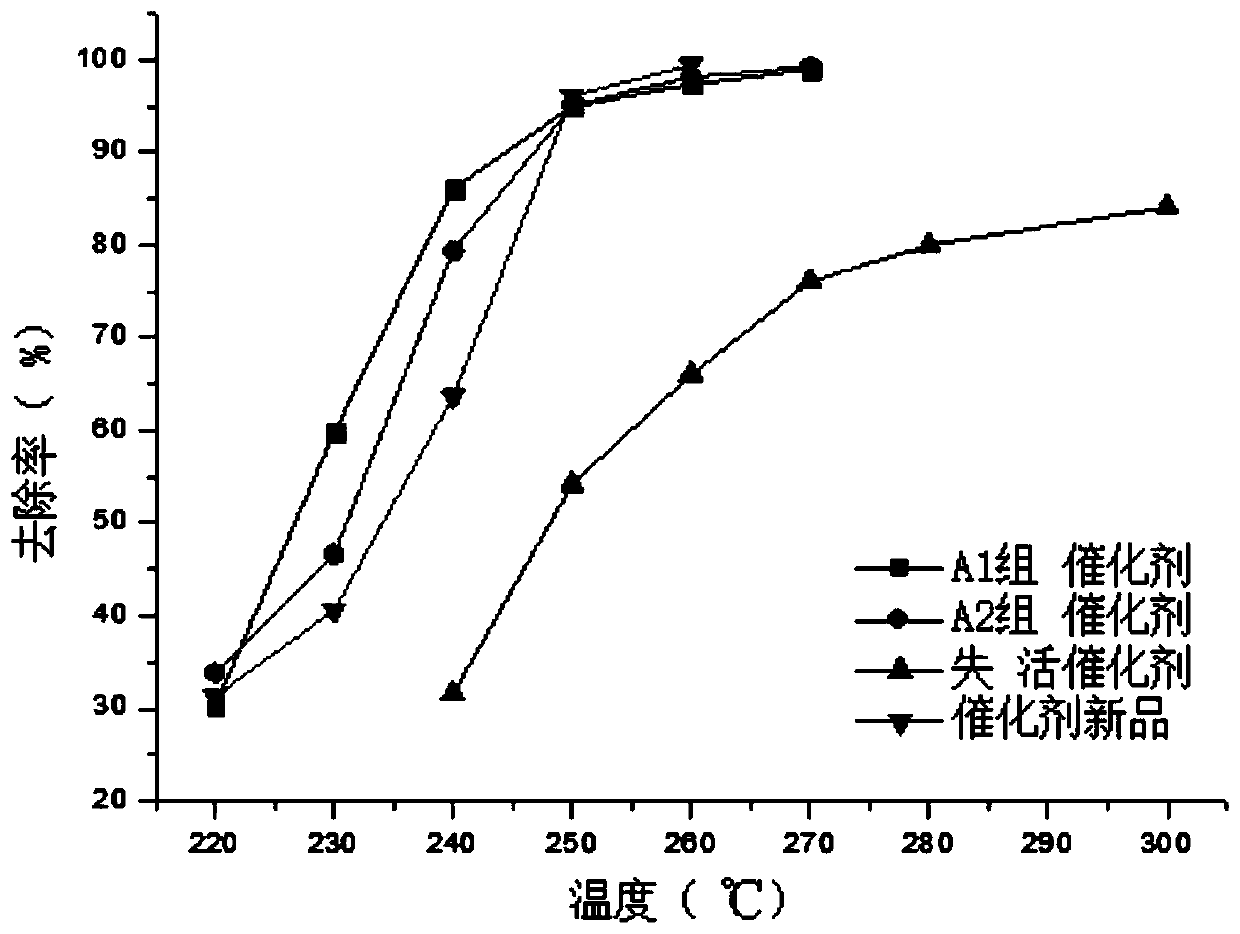

[0045] The above-mentioned deactivated group A catalysts are further subdivided into two groups of A1 and A2, and the A1 group is activated by using the activation replenishment liquid A liquid medicine (the active component distribution ratio is silver: manganese: cerium=1:3:4), and the A2 group is activated. The group was activated with the activation replenishment solution B potion (the distribution ratio of the active components was silver: manganese: cerium = 0.25:1.5:2, and the total amount of active components of the B potion was lower than that of the A potion). Active ingredients, group A2 belongs to insufficient supplementary active ingredients. Spray the potion and let it stand overnight, then introduce hot air at 80°C at a space velocity of 5000-10000h -1 Under certain conditions, dry for 4 hours, and then introduce hot air at 250°C at a space velocity of 3000-7000 hours -1 Calcined under the conditions for 4h, the activation regeneration is over. The catalysts o...

Embodiment 3

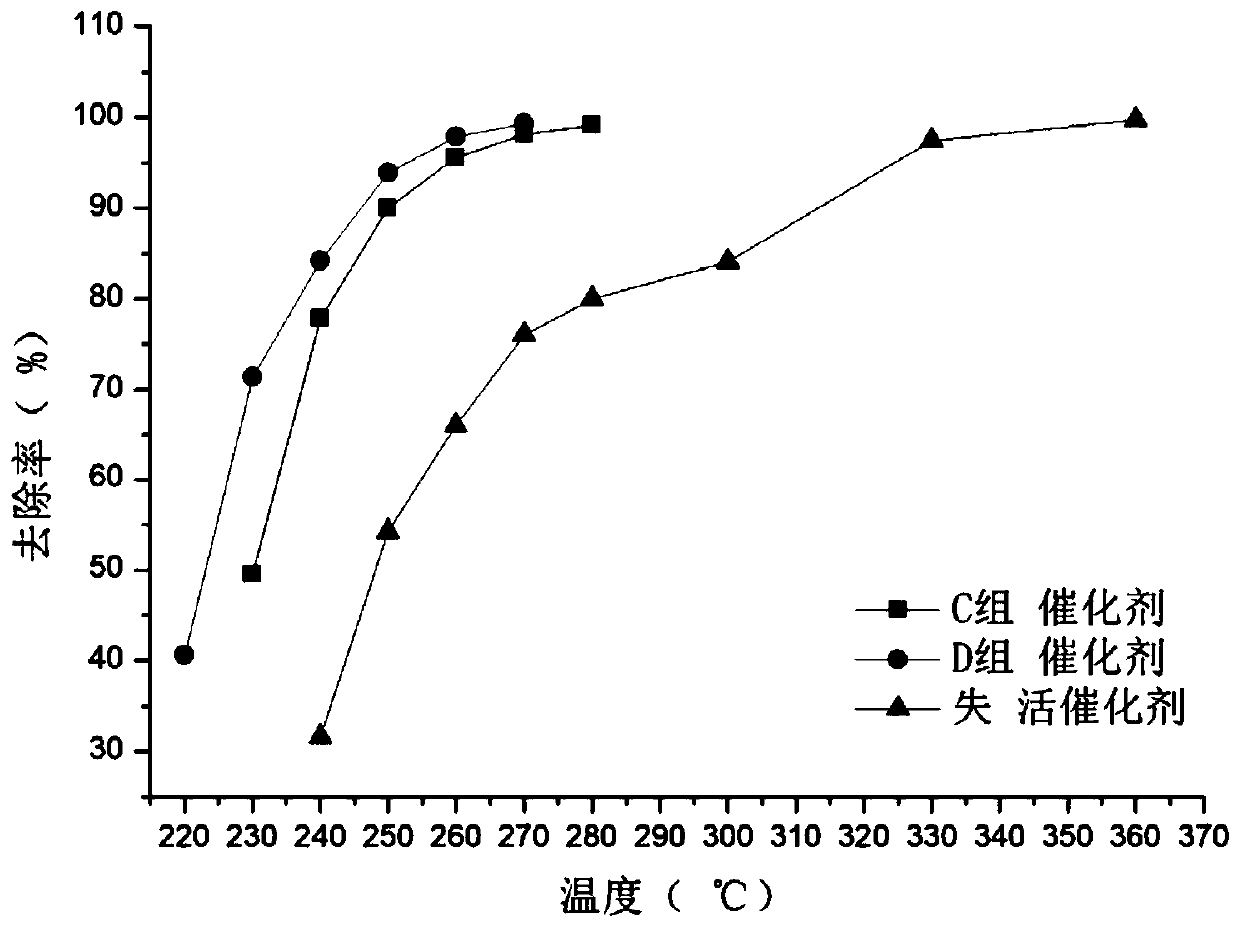

[0049] The catalyst sample comes from a petrochemical plant that has been running for about one year on the exhaust gas catalytic oxidation treatment equipment. Due to the change of the loading conditions of the plant, propane has been added to the exhaust gas, and the catalytic oxidation effect of the catalyst on propane is not good. It is divided into two groups C and D, and the active components of the catalyst are manganese, cerium and silver. Both groups of catalysts are now sprayed with potion E for on-line activation, wherein the active component of potion E is cobalt with a content of 0.1 to 15 wt%, and does not contain manganese, cerium and silver as active components of deactivated catalysts. The spray flow rate is 45mL / min, and the spray volume is 30% of the weight of the catalyst carrier. After spraying, let it stand overnight, and introduce hot air at 80°C at a space velocity of 5000-10000h -1 Under certain conditions, dry for 4 hours, and then introduce hot air a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com