A kind of preparation method of the mixture of glycolide and lactide

A technology of lactide and glycolide, applied in the field of easily degradable polymer monomers, can solve the problems of slow formation rate of cyclic dimer, difficult cleaning of the reaction kettle, large absorption, etc., and achieves the effect of weakening the carbonization phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

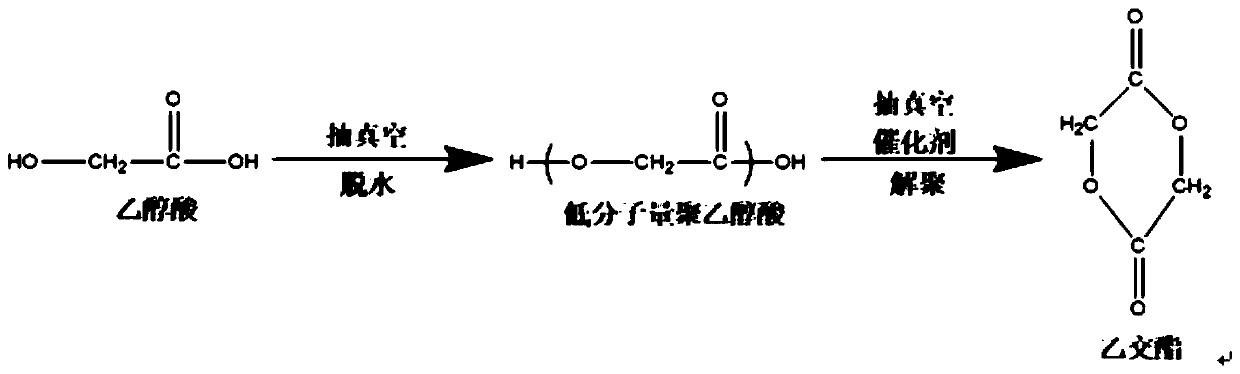

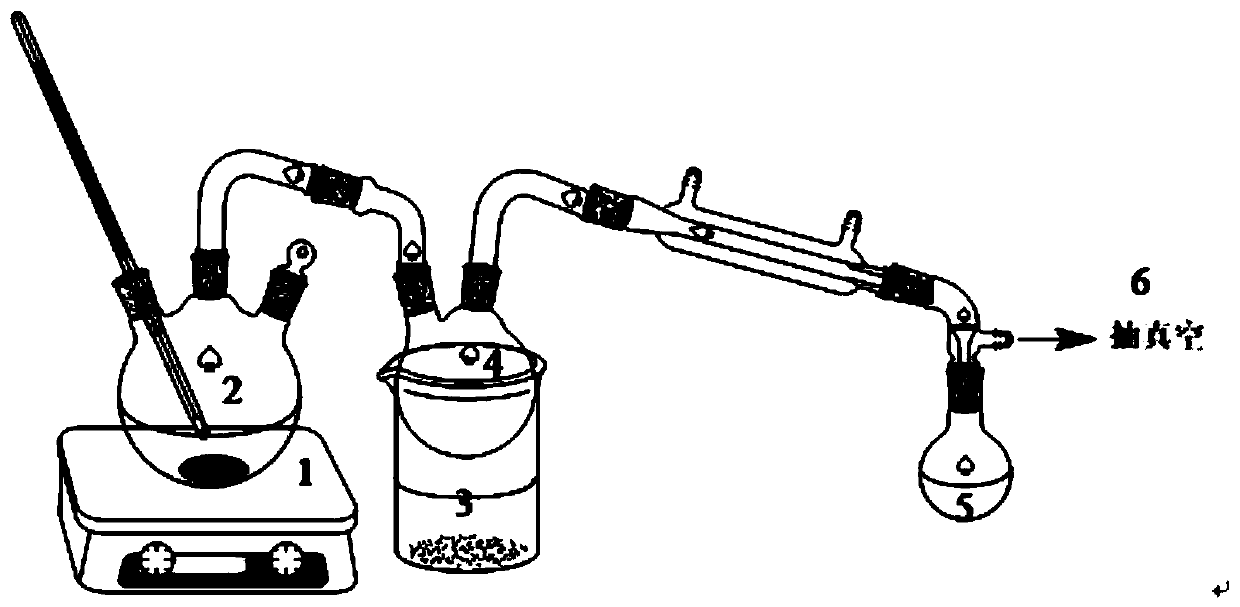

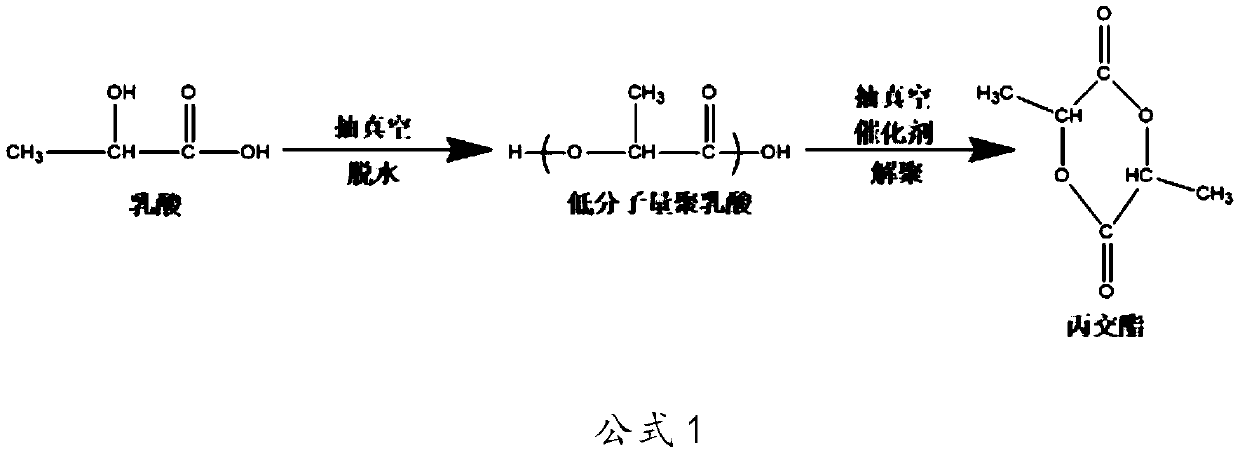

[0029] The preparation mechanism of this application is to synthesize a biodegradable polymer: polyethylene lactide, which requires polymerized monomers to include glycolide and lactide. When preparing glycolide, the depolymerization temperature of glycolide is higher (240-260°C), and carbonization is easy to occur during the reaction process. Compared with the preparation of glycolide, the generation (preparation) of lactide The depolymerization temperature is low (200 ~ 230 ° C). Based on this, the present application proposes a method for synthesizing glycolide, which mixes a certain proportion of polylactic acid oligomers that can generate lactide in the reactants that generate (synthesize) glycolide. Through such an embodiment, the generated lactide can increase the reaction interface of glycolide, accelerate the reaction of generating glycolide, thereby reducing carbonization; secondly, the generated product contains glycolide and lactide Lactide, for the synthesis of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com