Industrial production method of synthetic rubber and industrial device for implementing method

A production method and synthetic rubber technology, applied in the direction of chemical instruments and methods, feeding devices, chemical/physical processes, etc., can solve the problems of complex post-treatment process, low feed concentration, large energy consumption and material consumption, etc., and achieve improvement Single-pass conversion rate, avoid high energy consumption, achieve uniform control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 This example is to illustrate the preparation of high cis polybutadiene rubber by bulk polymerization of butadiene.

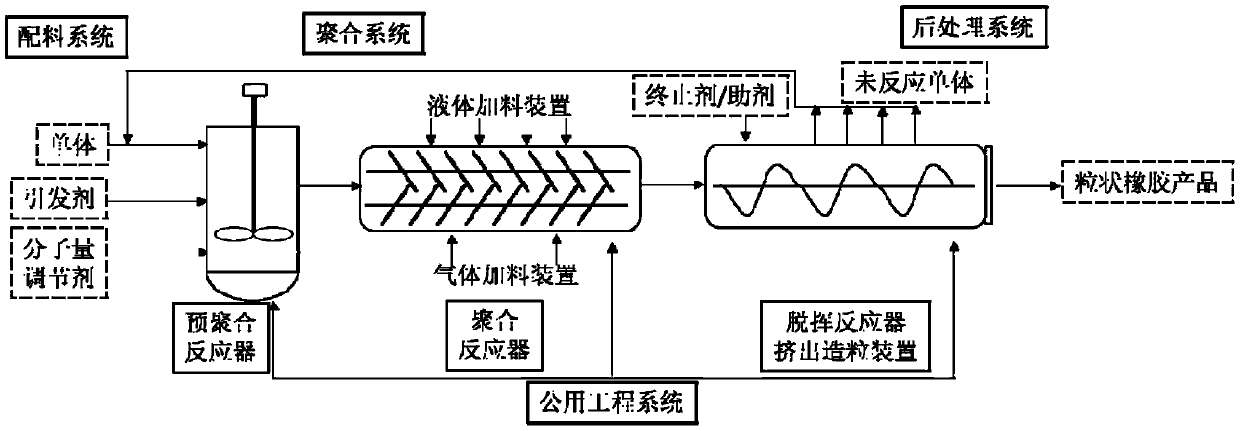

[0033] Industrial device: The pre-polymerization reactor is a tank reactor with stirring; the polymerization reactor is two parallel meshing self-cleaning reactors; the devolatilization reactor is two parallel twin-screw extruders; The device is two parallel twin-screw extruders.

[0034]Industrial production method: Polymerization grade butadiene (monomer purity>99.6%), rare earth catalyst, molecular weight regulator diisobutylaluminum hydride are sequentially injected into the kettle-type pre-polymerization treated with vacuum nitrogen anhydrous and oxygen-free through the metering device Reactor, the pre-polymerization temperature is 10°C, and the reaction time is 0.1 hour; then the material is transported to two parallel biaxial meshing self-cleaning reactors, the reaction temperature is controlled at 30°C, and the average residence time of...

Embodiment 2

[0035] Example 2 This example is to illustrate the preparation of high trans polyisoprene rubber by bulk polymerization of isoprene.

[0036] Industrial device: the pre-polymerization reactor is a tank reactor with stirring; the polymerization reactor is two meshing self-cleaning reactors connected in series; The device is a twin-screw extruder.

[0037] Industrial production method: inject polymerization-grade isoprene monomer (monomer purity>99.5%), titanium catalyst and molecular weight regulator hydrogen into the pre-polymerization reactor treated with vacuum nitrogen anhydrous and oxygen-free through a metering device, The prepolymerization temperature was -10°C, and the reaction was carried out. The reaction time of the prepolymerization reactor was controlled to be 2 hours. The material is transported to the biaxial meshing self-cleaning reactor, the reaction temperature of the first meshing self-cleaning reactor is controlled at 40°C, the reaction temperature of the ...

Embodiment 3

[0038] Example 3 This example is to illustrate the preparation of high trans-butadiene-isoprene copolymer rubber by bulk polymerization of isoprene and butadiene.

[0039] Industrial device: the pre-polymerization reactor is a tank reactor with stirring; the polymerization reactor is two meshing self-cleaning reactors connected in series; The device is a twin-screw extruder.

[0040] Industrial production method: polymerization grade isoprene and butadiene monomer (monomer purity>99.5%) according to isoprene:butadiene=90:10 (molar ratio), titanium tetrachloride type Zieg The Le-Natta catalyst and the molecular weight regulator hydrogen are sequentially injected into the kettle-type prepolymerization reactor treated with vacuum nitrogen anhydrous and oxygen free through the metering device, and the prepolymerization temperature is 0°C to carry out the reaction. Control the prepolymerization reaction time to be 1 hour. The material is transported to the biaxial meshing self-cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com