Treatment method for stinky waste gas discharged by storage tank

A treatment method and waste gas treatment device technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as poor stability, tail gas discharge that cannot meet standards, and stricter requirements, and achieve high absorption efficiency. Recycling and discharge of other impurities, and the effect of improving the treatment rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

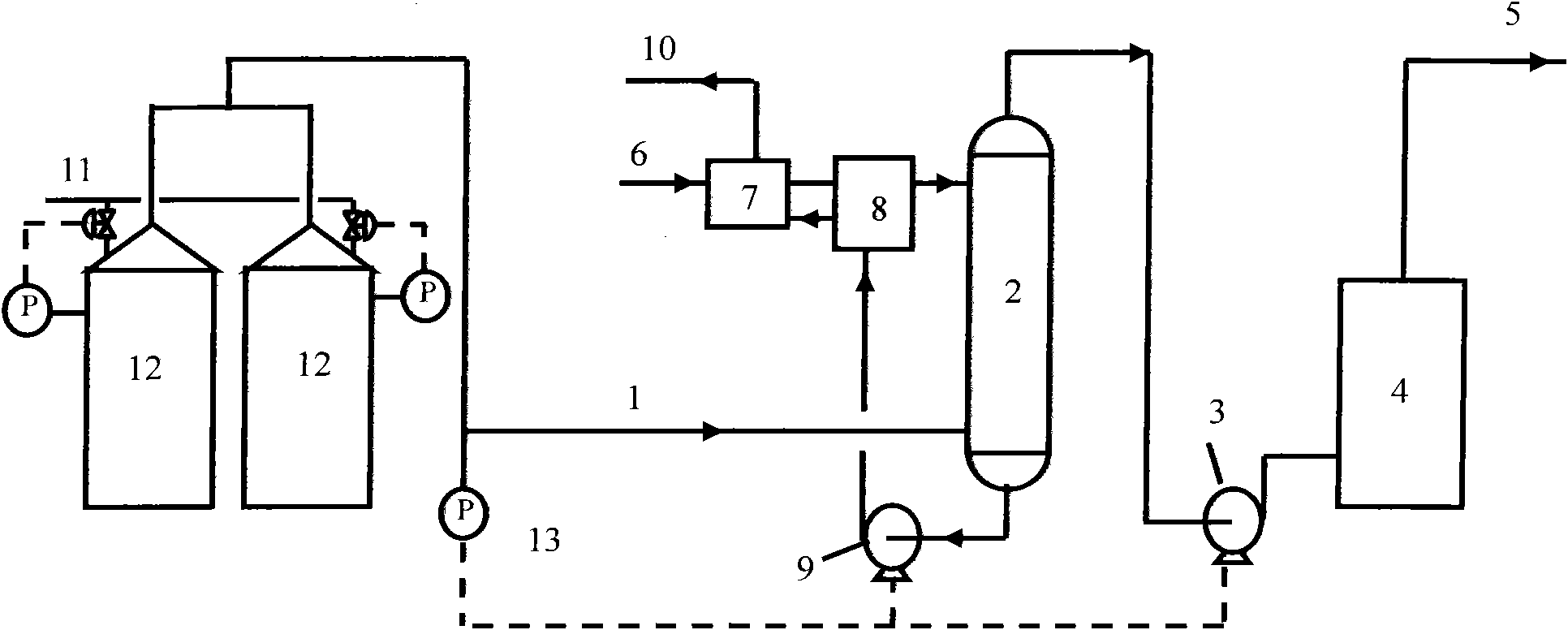

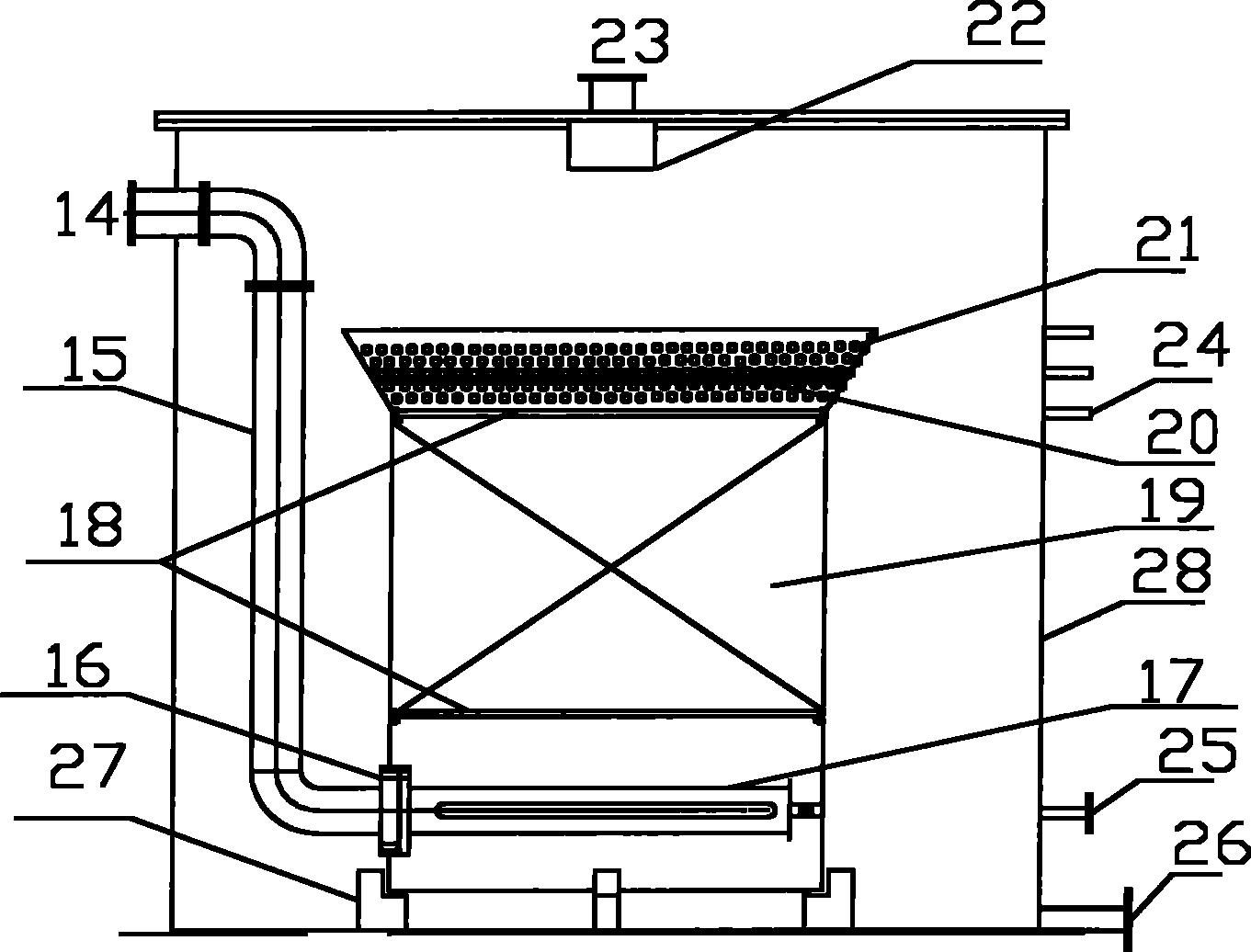

[0049] Hydrogen sulfide 5000mg / m3 in waste gas from sour water tank area of an oil refinery 3 , dimethyl disulfide 100mg / m 3 , thiophene 60mg / m 3 , total hydrocarbon concentration 20×10 4 mg / m 3 , the flow rate is 100Nm 3 / h. use as figure 1 In the process flow shown, the exhaust gas is discharged intermittently. When the pipeline pressure is greater than 1000Pa, the gas delivery pump 3 is started and the rich absorption oil pump 9 and the refrigeration unit 8 are started at the same time. The desulfurization reactor adopts such as image 3 In the structure shown, the sodium hydroxide aqueous solution is used as the desulfurization absorption liquid in the desulfurization reactor, and fresh lye is replaced when the pH value of the working liquid drops to 9. The absorption tower is filled with Dg38 packing ring. The absorbent adopts catalytic cracking gas oil fraction with a distillation range of 180-380°C, and the sulfur content is 0.8% based on sulfur mass. The low-t...

Embodiment 2

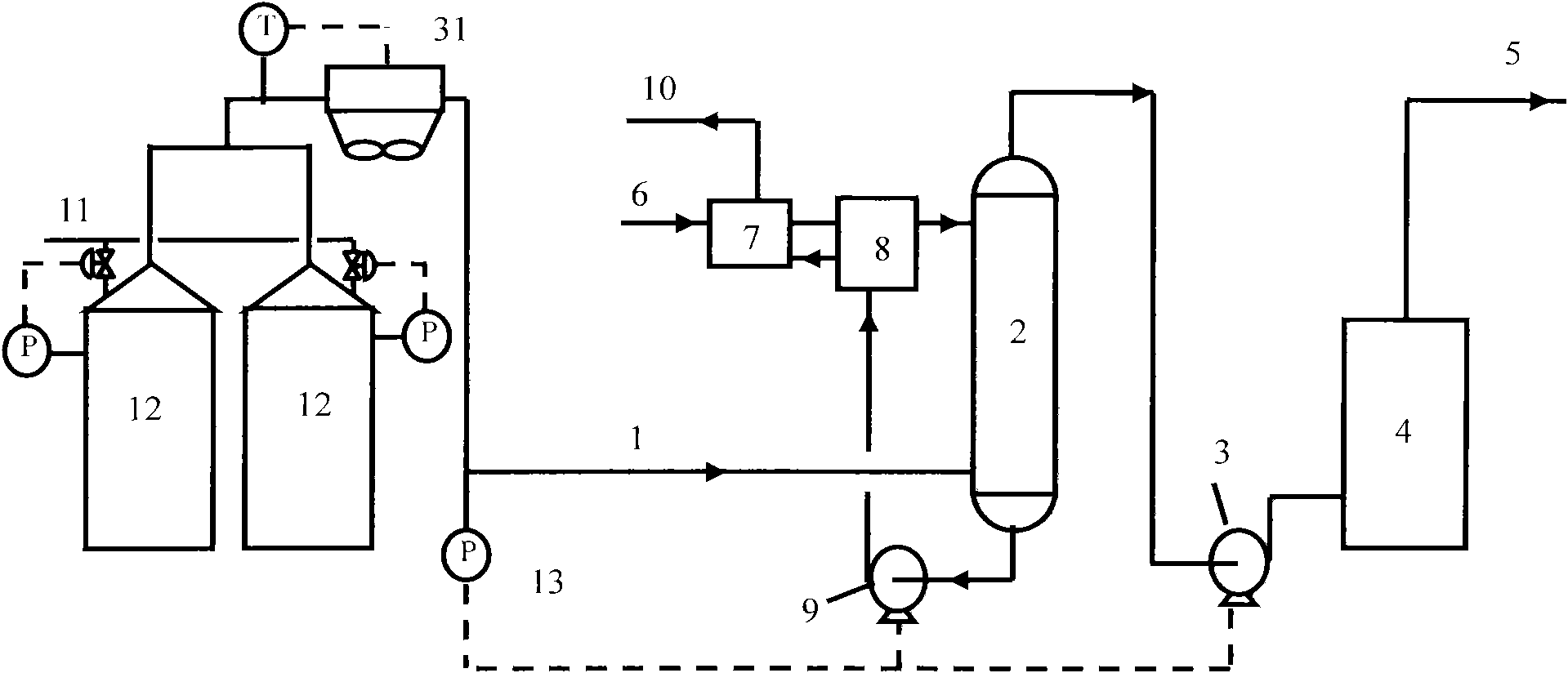

[0052] Hydrogen sulfide 1000mg / m3 contained in waste gas from a waste oil tank area of an oil refinery 3 , dimethyl disulfide 300mg / m 3 , methyl mercaptan 60mg / m 3 , total hydrocarbon concentration 20×10 4 mg / m 3 , the flow rate is 150Nm 3 / h. During operation, 1000m3 / h of water vapor purge gas is intermittently sent into the storage tank, such as figure 2 In the process flow shown, the waste gas condenser is an air cooler. When a large amount of waste gas is discharged, the temperature of the waste gas in the discharge pipe is higher than 60°C. At this time, the fan of the air cooler is started, and the air cooler starts to run. When the pressure of the pipe is greater than 30000Pa, the gas delivery pump 3 is started and the rich absorption oil pump 9 and the refrigeration unit 8 are started at the same time. , the absorbent is FCC diesel with a sulfur content of 1.2%, and the desulfurization reactor adopts such as image 3 In the structure shown, sodium hydroxide s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com