A kind of nickel-manganese-based positive electrode material precursor and the synthesis method of positive electrode material thereof

A positive electrode material and synthesis method technology, applied in the field of lithium ion battery material preparation, can solve the problems of electrochemical stability and low charge and discharge capacity, long co-precipitation reaction time, difficult filtration, etc., to achieve stable electrochemical performance, and each component Uniform distribution and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

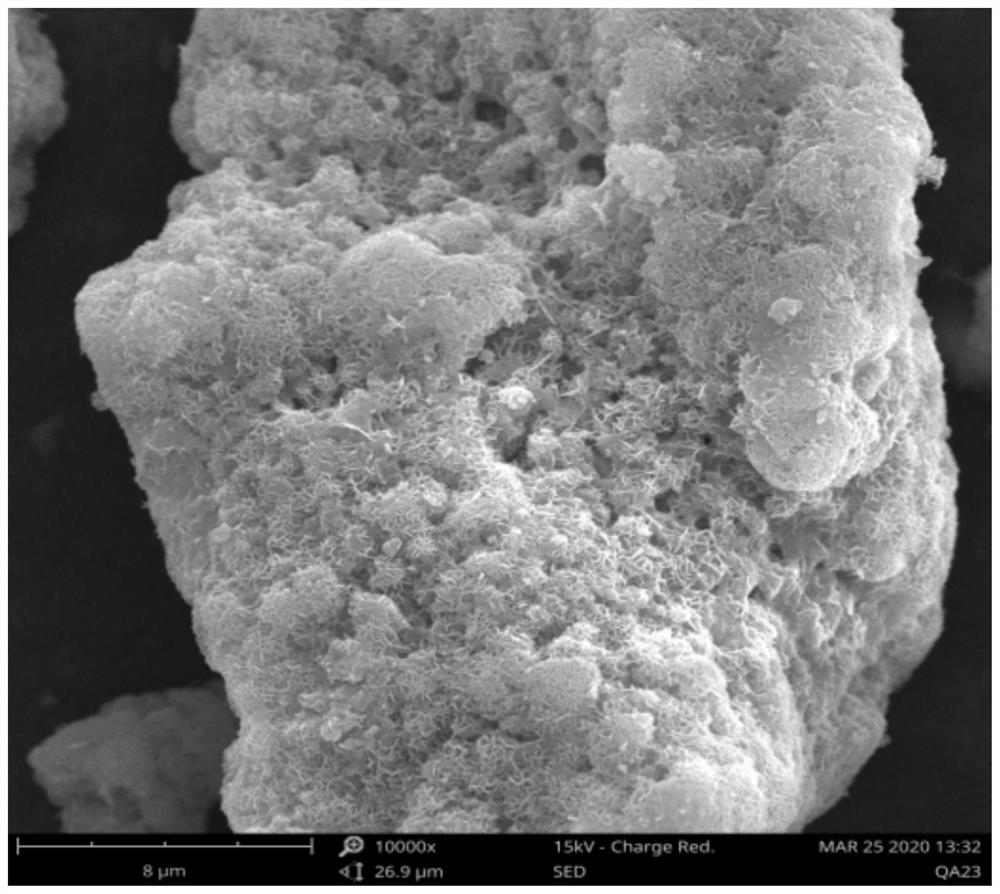

[0039]Take 416.3g of battery-grade nickel sulfate hexahydrate, 27.38g of battery-grade manganese sulfate monohydrate, 36.3g of battery-grade aluminum sulfate octadecahydrate, add deionized water, and prepare a 1L solution, which is converted into nickel sulfate, manganese sulfate, and aluminum sulfate The total metal ion concentration in the mixed aqueous solution is 1.8mol / l, which is solution A; take 144g of analytically pure sodium hydroxide, add deionized water, and be prepared into a 1L solution, and the converted sodium hydroxide concentration is 3.6mol / l, which is for solution B. Add 450ml of bottom water (deionized water) into a 3L reactor, first place 2.11g of nano-metal nickel powder and 1.98g of nano-metal manganese powder in the reactor, and then pump A solution and B solution into the 3L reactor at the same time Co-precipitation reaction is carried out, the reaction conditions are: stirring intensity: medium, feeding time 30min, reaction time 1.0h, aging time 0.5h...

Embodiment 2

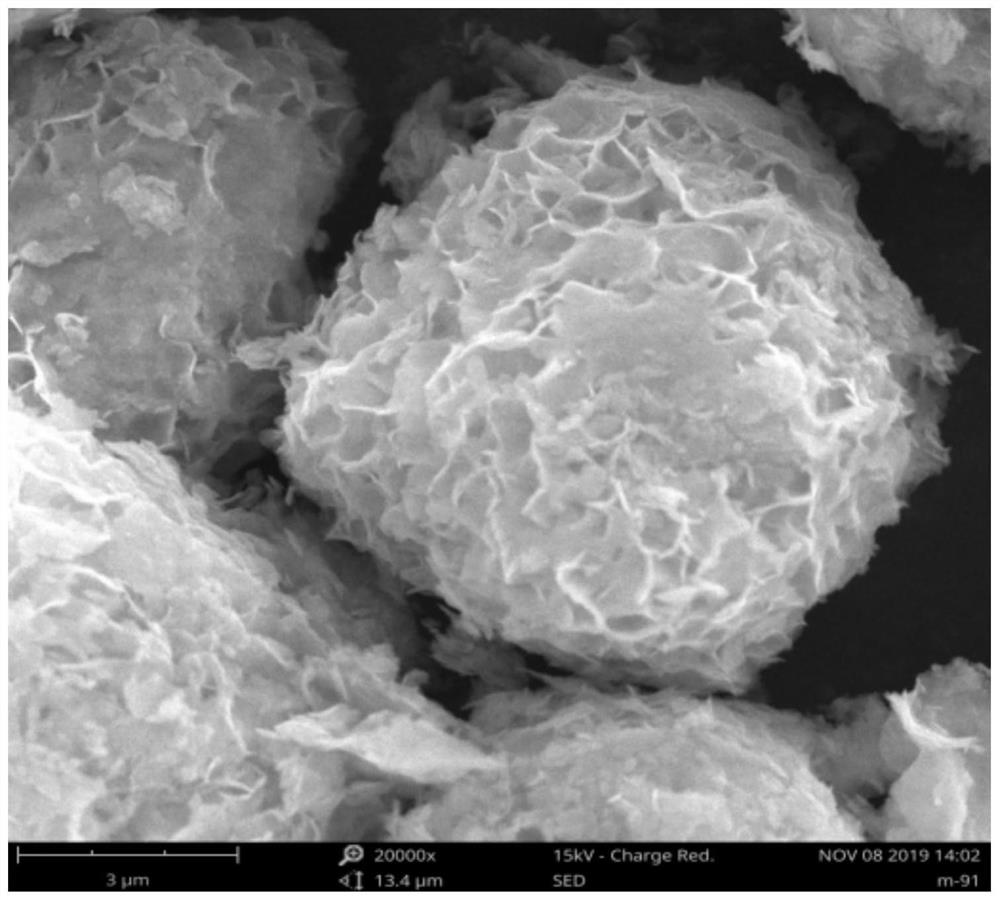

[0041] Take 416.3g of battery-grade nickel sulfate hexahydrate, 27.38g of battery-grade manganese sulfate monohydrate, 36.3g of battery-grade aluminum sulfate octadecahydrate, add deionized water, and prepare a 1L solution, which is converted into nickel sulfate, manganese sulfate, and aluminum sulfate The total metal ion concentration in the mixed aqueous solution is 1.8mol / l, which is solution A; take 144g of analytically pure sodium hydroxide, add deionized water, and be prepared into a 1L solution, and the converted sodium hydroxide concentration is 3.6mol / l, which is for solution B. Add 450ml of bottom water (deionized water) into a 3L reactor, first add 2.68g of nickel oxide powder and 2.55g of manganese oxide powder into the reactor, and then pump A and B solutions into the 3L reactor at the same time for co-precipitation reaction , The reaction conditions are: stirring intensity: medium, feeding time 30min, reaction time 2h, aging time 1h, reaction temperature 80°C. V...

Embodiment 3

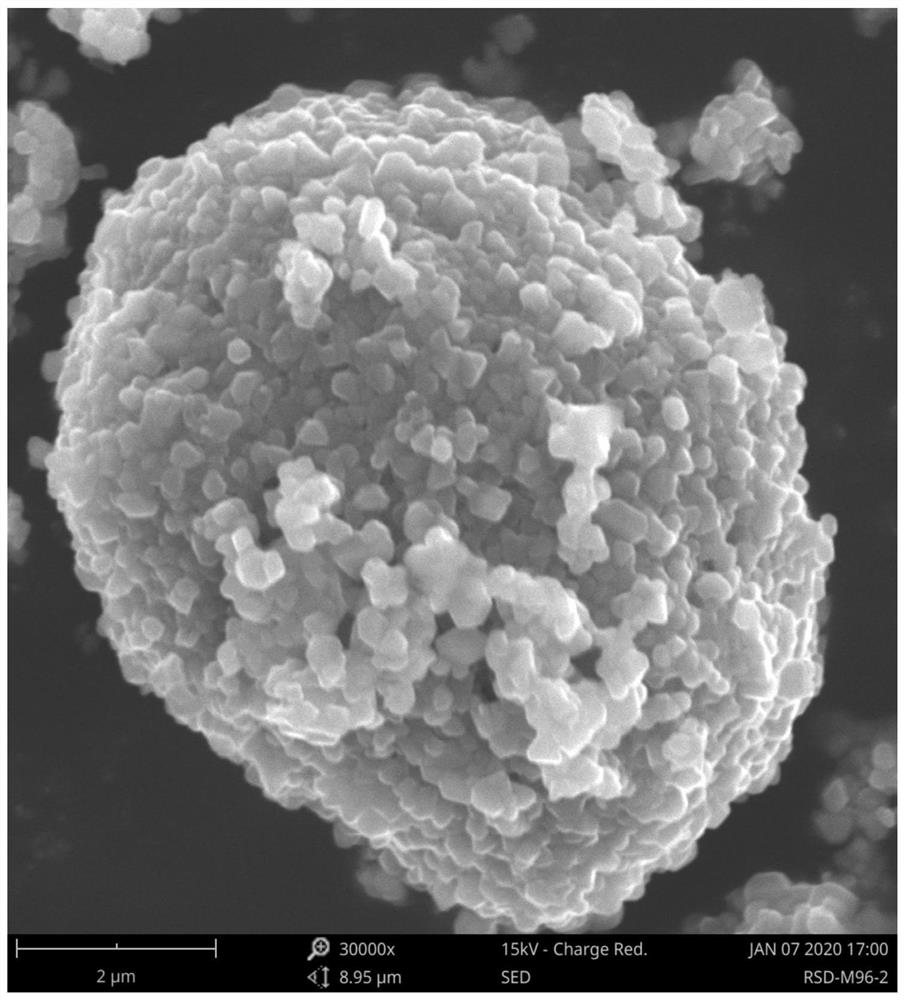

[0043] Take 416.3g of battery-grade nickel sulfate hexahydrate, 27.38g of battery-grade manganese sulfate monohydrate, 36.3g of battery-grade aluminum sulfate octadecahydrate, add deionized water, and prepare a 1L solution, which is converted into nickel sulfate, manganese sulfate, and aluminum sulfate The total metal ion concentration in the mixed aqueous solution is 1.8mol / l, which is solution A; take 144g of analytically pure sodium hydroxide, add deionized water, and be prepared into a 1L solution, and the converted sodium hydroxide concentration is 3.6mol / l, which is for solution B. Add 450ml of bottom water (deionized water) into a 3L reactor, first add 5.28g of metal Ni powder and 4.944g of Mn powder into the reactor, and then pump the A and B solutions into the 3L reactor at the same time in parallel for co-precipitation reaction. The reaction conditions are: stirring intensity: medium, feeding time 30min, reaction time 2h, aging time 1h, reaction temperature 80°C. Va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com