Silane modified polyether adhesion sealant

A silane-modified polyether, bonding and sealing technology, which is applied in the field of building decoration materials, can solve the problems of affecting human living environment and living environment, failure to form good bonding, environmental damage, etc., to achieve good bonding, bonding Good bonding effect and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A kind of preparation method of silane modified polyether adhesive sealant provided by the invention, the preparation method of described silane modified polyether adhesive sealant comprises the following steps:

[0031] S1. At room temperature, add plasticizers and fillers to the mixing kettle, control the rotation speed of the planetary stirring to 300rpm, and the rotating speed of the dispersing disc at 600-800rpm. After stirring for 10 minutes, raise the temperature to 110°C, and adjust the rotating speed of the planetary stirring to 500rpm. Rotate at 800-1000rpm, turn on the vacuum, dehydrate at 110°C for 2 hours, measure the moisture content to below 200ppm, cool to below 50°C to prepare the base material;

[0032] S2. At room temperature, add a dehydrating agent to the base material in step S1 and stir evenly, then add silane-modified resin and stabilizer in turn, adjust the planetary stirring speed to 600rpm, the speed of the dispersion disc to 800-1000rpm, and s...

Embodiment 1

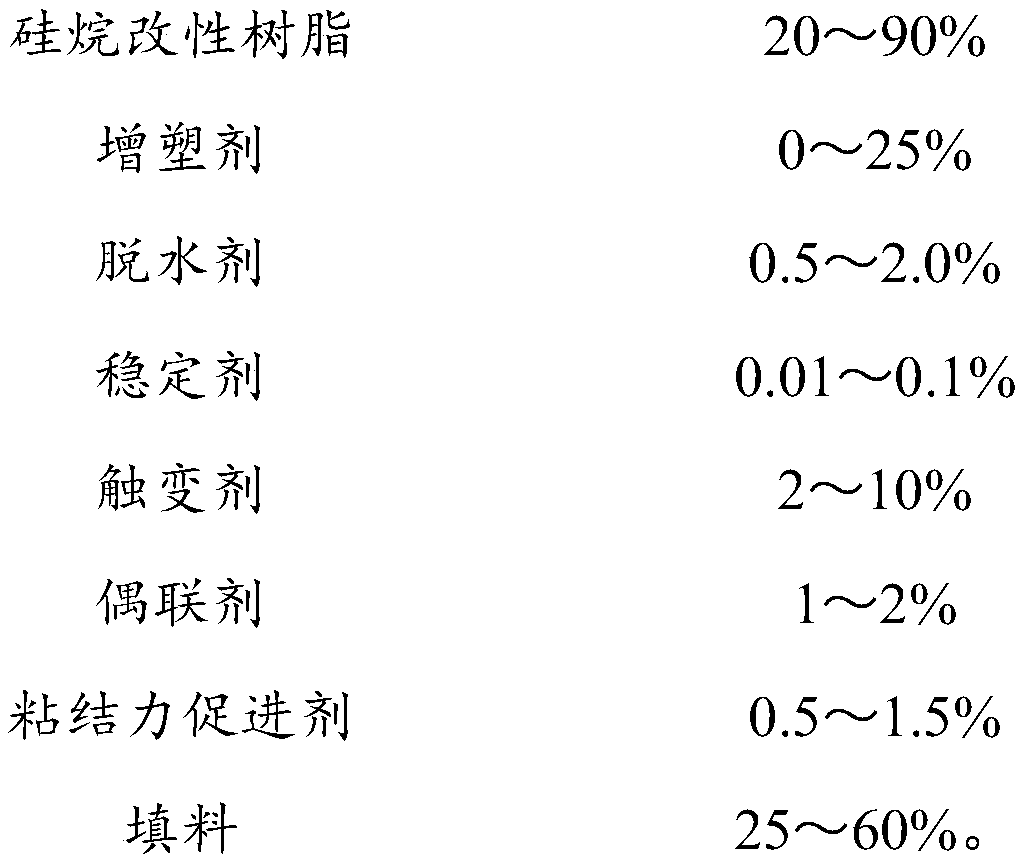

[0037] In Example 1, the silane-modified polyether sealant comprises the following components:

[0038]

[0039] In this example, first add silane-modified polyether resin and plasticizer PPG2000 into the mixing tank according to the formula amount, after mixing evenly, add fillers in sequence, the fillers include: ground calcium carbonate, nano-calcium carbonate and titanium dioxide , after stirring evenly, add fumed silica and polyamide wax as thixotropic agent, heat to 110°C, stir and vacuum dehydrate for 2h.

[0040] Then protect the mixed material in the mixing kettle with nitrogen gas, cool it to below 50°C, add dehydrator A171, coupling agents A1110 and A187, and adhesion promoter, stir evenly, add stabilizer B75, and continue stirring for 10 minutes. Then add catalyst U220H, vacuumize, continue to stir for 10 minutes, then fill with nitrogen to normal pressure, discharge and pack to obtain silane-modified anti-mildew sealant.

Embodiment 2

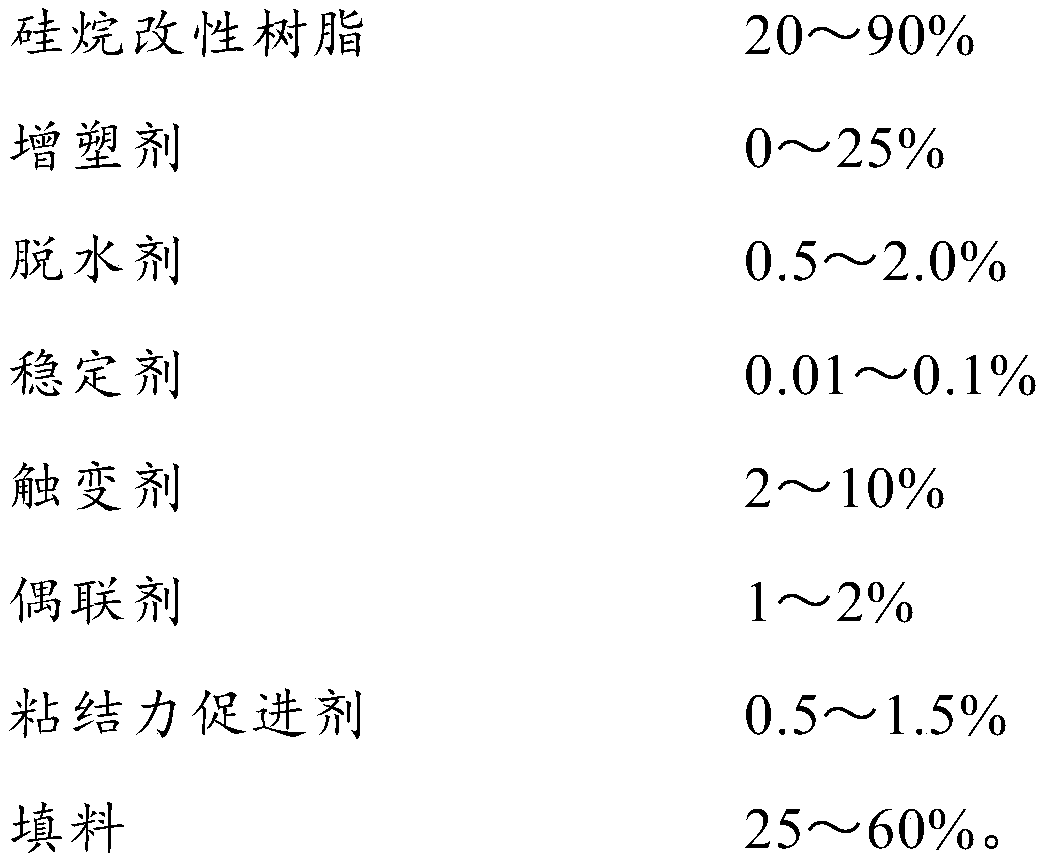

[0042] In Example 2, the silane-modified polyether sealant comprises the following components:

[0043]

[0044] In this example, the preparation method of the silane-modified polyether sealant is basically the same as that in Example 1, the only difference being that the silane-modified resin is mixed uniformly with the plasticizer and the filler and dehydrated, and the temperature drops to Add after reaching below 50°C.

[0045] It should be noted that, in this embodiment, the silane-modified polyether sealant has good mildew resistance and high performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com